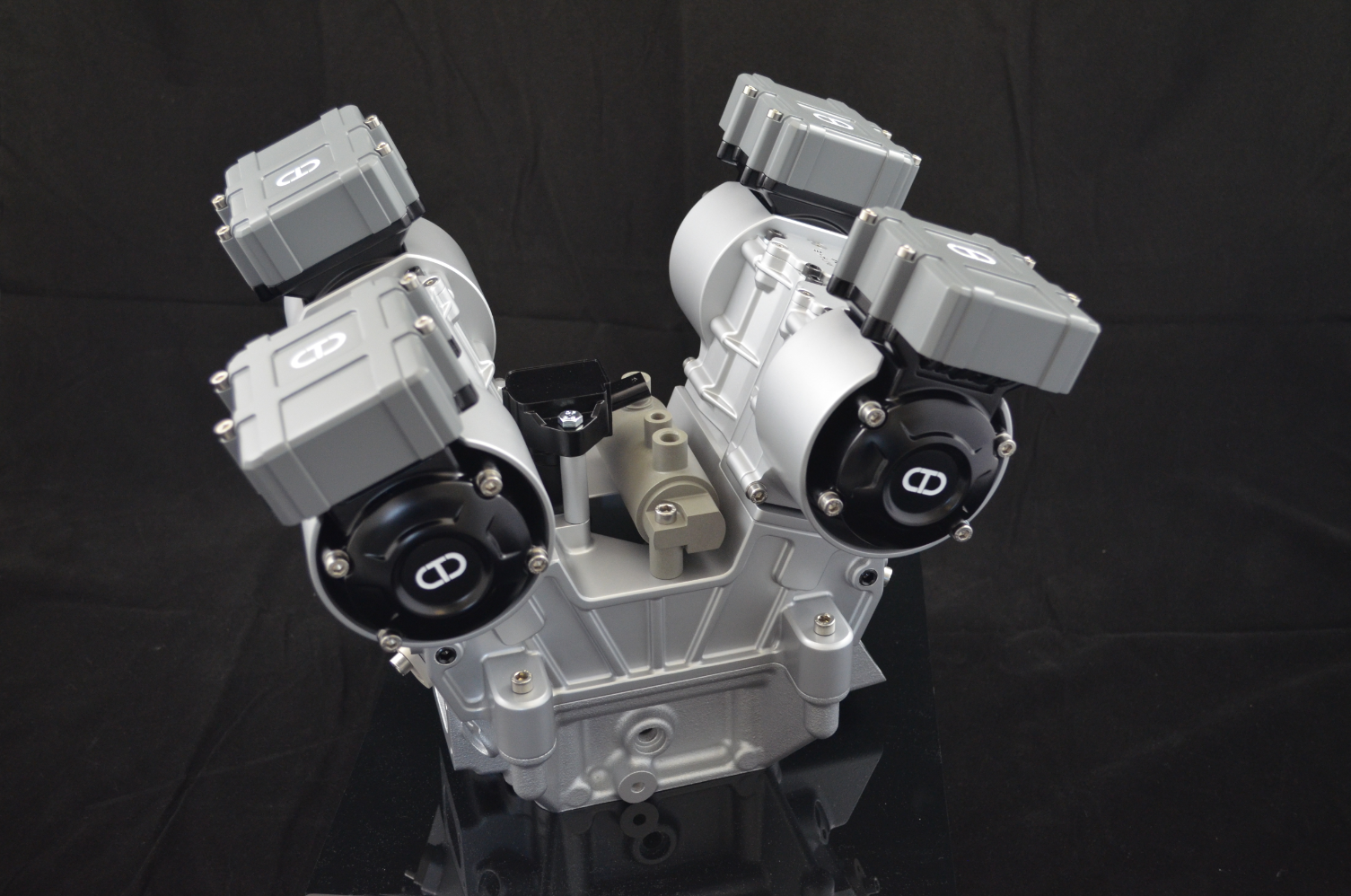

An intricate 3D model of a valve system to boost engine operation and cut carbon dioxide output has allowed an automotive company to showcase its pioneering technology to the world.

As governments and organisations seek to improve performance and efficiencies across all industries, Camcon Automotive has ‘achieved the impossible’ by bringing the last key element of engine combustion under digital control.

The company’s revolutionary core solenoid technology has seen the creation of the iVT (intelligent Valve Technology) system, allowing fully electronic control of valve events and realising the potential for improved engine operation and reduced CO2 output.

Camcon worked alongside Brighton-based Furnace Design to come up with the component before turning to Ogle Models in Hertfordshire to produce a scale replica.

Matt White, Senior Prototype Engineer at Ogle, said: “As the part was to be used for promotion at trade visits, exhibitions and prospective client meetings, it was imperative that the part looked realistic. This required a high level of paint work to mimic the multiple metallic finishes; cast metal, injection moulded parts and steel.

“To effectively 3D print the part, the CAD needed to be broken down and each component printed separately. Our skilled and experienced model makers worked hard to ensure the parts all fit seamlessly together.

“The main cylinder head was produced using SLS which not only allows for complex geometry but is self-supporting with high tensile strength. The accuracy achieved was +/- 0.12mm per 100mm.”

Camcon required parts of the model to be dismantled and reassembled to fully display the complex interior of the model, with Ogle undergoing a rigorous testing process to ensure accuracy.

Mr White added: “It’s great for our team to work on such revolutionary projects that we know will end up changing or shaping their industry. It was a pleasure to work with Furnace Design and deliver the part on time and on budget.”

The part is now flying across the globe to appear at a string of high-profile exhibitions.

Owen Evans, Director at Furnace Design, said: “We have worked with Ogle before as they are highly regarded within the industry. We knew who to turn to when we needed a complete start-to-finish service and wanted to see the finished part as accurately presented as possible. Ogle were the first port of call. Their team also managed to hit a very tight deadline which was remarkable.”

For more information about Ogle Models visit https://www.oglemodels.com/