A growing number of car manufacturers are deciding to utilise high-voltage equipment with a view to enhancing the comfort of driving or general vehicle users’ experience. However, it is connected with a higher demand for additional electric power supply. This problem is not going to be solved by adding new energy sources – which results in increasing vehicle weight and dimensions – but by a more effective use of the existing solutions.

This is why EPC (Electronic Power Control) systems used as performance adjusters have become more common. These systems are exposed to EMI regulations of OEM car manufacturer to not interfere with other devices in the vehicle. Therefore, chokes are used to reduce these interferences and attenuate the noise generated by the device. Material capabilities are key to comply with EMI regulations and given space and weight targets, research and development is meanwhile underway to produce the core material, whose aim is to produce smaller, cheaper and, most importantly, more efficient products.

The result of these efforts is the 7HT material used in KEMET chokes in the SC series and other customized products. Compared with the previous 5HT material this ensures 40% better noise attenuation with the same equipment parameters – in particular its size. Depending on clients’ requirements, KEMET is able to the right magnetic solution for individual project needs. This level of performance is retained even at 150°C, which makes it a perfect solution that can be installed close to vehicle engines and within high power and drive train DC/DC converter

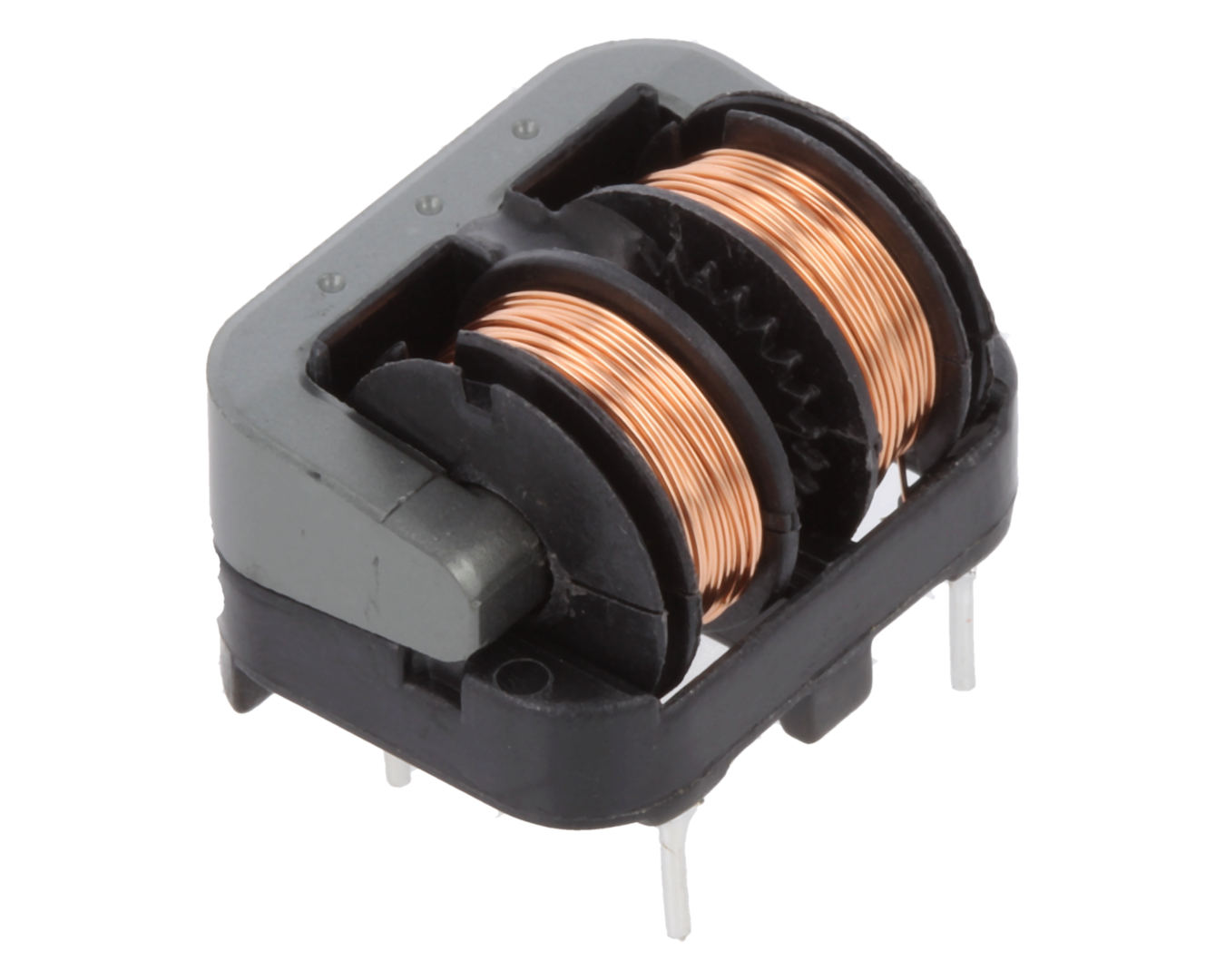

Common and differential mode chokes

A choke comprises a ferromagnetic toroidal core around which a wire is wound. According to the Faraday’s law of electromagnetic induction, current flow generates a magnetic field, and the ability to generate it is expressed in Henry [H]. Each variable magnetic field results in generating variable electromotive power in a circuit, i.e. current flowing in the reverse direction (opposite to the primary one). Electro magnetic interferences caused by switching semiconductors of higher frequency from induct a magnetic field and flux into the material that convert to core losses and a heat rise of the magnetic material. EMI energy is converted into heat and such as filtered from the power lines.

In differential chokes, a wire is wound only on one side, which results in the fact that, regardless of the current flow direction, noise is filtered by current converting to magnetic energy and finally heat. Although noise is absorbed in both the higher and lower frequency ranges the supply of DC or AC voltage causes a continues magnetic field and losses and requires materials with high saturation capabilities, usually Iron power cores are used and other materials with high saturation.

This situation is different in common mode chokes, as in such chokes two coils are wound instead of one with opposite magnetic flux inducted that cancels each other out. This means that only an interference current, common mode current is leading to magnetic flux and a heat rise in the material. Saturation capabilities only need to be as high as the interference current. Depending on the interference behaviour those are described as asymmetric interferences that need differential mode chokes or Y-capacitors and symmetric interferences that need common mode chokes or X-capacitors to attenuate and comply. The majority of KEMET chokes operate in the common mode, so they offer a perfect solution in applications where removal of noise and related electromagnetic interferences is necessary. Depending on the product the differential mode (leakage) behaviour of a common mode choke can be used to design dual mode chokes that combine both attenuation behaviors. Application of the 7HT material significantly enhances their performance and decreases their size while keeping the saturation behaviour stable and under control.

Ferrite material magnetic permeability

In order to ensure effective noise reduction, a material that is compatible with the target frequency band must be selected. Depending on its magnetic permeability, a given ferrite material will be effective within a given frequency band. Mn-Zn materials demonstrating higher magnetic permeability in lower frequency bands, Ni-Zn materials with lower magnetic permeability attenuate better in higher frequency ranges.

Ambient conditions and choke operation

A considerable advantage of chokes with 7HT common mode chokes is their ability to operate at large current loads (up to 25A and more). Operating conditions for such chokes are defined by:

- maximum ambient temperatures (in this case it is 150°C)

- Isolation requirements due to supply voltage and OEM requirements

- temperature rise resulting from choke power losses

Chokes with 7HT cores are smaller than those with 5HT cores, which makes them more vulnerable to ambient conditions. SC series models available in the KEMET assortment as customized solutions. This considerably facilitates their broad-range application in strenuous conditions, e.g. in engine systems. For automotive applications, the SC series chokes are only available in a customised version. To make designs and development cost affordable for customers certain quantity conditions would apply to proceed with an individual project. For more information on KEMET chokes, visit the distributor’s site – tme.eu.