Advanced technology and sensitive applications requirements increase the need for EMI reduction

A look back at Magnetic Shields news and significant activities for this past year include university and lab projects, ISO certification, custom parts and fabricated shields, and expanded shielding product line sizes offered to mitigate low frequency field disturbances. As the new year approaches, we look forward to continuing to build strong relationships with our clients, partners, OEMS, engineers in the functions of design, electric, electrical, technical professions, scientists, physicists, students, professors and more.

Our brands such as cold rolled MuMETAL®, Co-NETIC®, and Cryo-NETIC® alloy material compositions contain high, or mid percentages of soft magnetic nickel-iron alloys, except for NETIC® which is a high iron alloy that can be used in layers with spacing between to attain high saturation in combination with high permeability mumetal when necessary for stronger magnetic field forces. Whereas the Cryo-NETIC is a high Ni-Fe alloy used in extreme low temperature conditions or applications. Foil, sheet, and plate are readily available for rush orders and next day shipping when the project timeline and specifications indicate sourcing industry referenced MuMETAL for performance shielding. Magnetic Shield has you covered.

High Tech University and Lab Projects

Significant news stories that were shared this last year briefly detailed our successful shielding installations at two prominent USA scientific technical universities. Our new state-of-the-art MuROOM® installation at the University of Illinois (UOI) Champaign-Urbana USA, Electron Microscopy (EM) facility within the notably renown Materials Research Lab (MRL) was completed. The UOI’s progressive research environment is considered to be at the forefront of industry in materials science, condensed matter physics, and materials chemistry.

The MuROOM project built by Magnetic Shield Corporation USA, was constructed using our high permeability MuMETAL® for advanced low-field testing applications. A large scale custom modular MuROOM was built to their design specifications with perfection annealed sheet that is ready for design installations. Our high nickel-iron composition sheet material is processed through our specialized heat treatment which produces the optimum shielding necessary to conduct high technology experimentation. Our MuROOM team builds the modular room on location at your designated area or facility.

In addition, the next large scope project was finished at Virginia Polytechnic Institute in the Carilion School of Medicine and Research center (VTCRI), located in Roanoke, VA. VTI designed and built the MuROOM® in partnership with Magnetic Shield Ltd. UK, and in cooperation with Magnetic Shield Corp. USA. Our MuROOM USA team from Magnetic Shield constructed the modular room on-site to their exacting specifications.

National and government lab facilities, R & D institutions, and universities world-wide continue to trend showing increased interest in our specialty shielding alloys, Zero Gauss Chambers, and engineering lab kits for prototyping in addition to the MuROOMS.

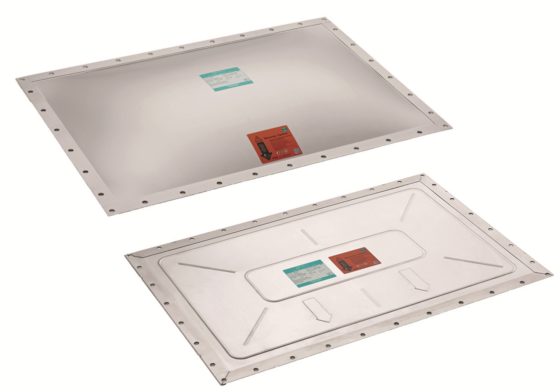

Prototyping, Custom Shields, and Rapid CNC Production

Since 1941 Magnetic Shield has been helping tech professionals resolve problems with EMI low field disturbances and bringing quality solutions to world-wide markets. We continue to offer our full capabilities from parts prototyping and fabrication, custom designed shielding enclosures, specialized hydrogen annealing, CNC low to high batch production, to manufacturing parts finishing, services and tooling.

Highly in-demand raw alloy materials are stocked in various forms for low field shielding protection of parts, components, devices, equipment, machinery and systems. Both stress-annealed and perfection annealed or hydrogen heat treated foil and sheet which are fabrication ready are stocked in warehouses either at the Chicago corporate office or the west coast California area. Other forms, shapes and products can be sourced in thicker plate, continuous coil, round bar, tube, mucans, mucores, and wiring products including our proprietary AA CABLE SHIELD®.

ISO Advantage

Retaining our ISO 9001:2015 earned certification is a major factor in helping us to increase consistent and accurate transactions and processes with methods to track and report items that need closer attention. The ISO program is ongoing and long term in order to manage and enhance our internal processes and operations, resources, and quality initiatives in our efforts to provide the highest level of client support and superior performance shielding solutions in the market.

Expansion of Product Lines

Our MuMETAL® brand continues to grow with added coil, bar and plate forms. Expansion of thicknesses and sizes include our stock alloy types in foil and sheet, and the Zero Gauss Chamber. Read about our products below.

- MuMETAL Deep Draw Quality Coil, continuous coil length quantity

- MuMETAL Round Bar, ten sizes / thicknesses available

- NETIC S3-6 Stress Annealed Sheet, layer with mumetal to absorb stronger fields

- MuMETAL Perfection Annealed Foil (fully annealed)

- Co-NETIC AA Perfection Annealed Foil, fabrication ready

- Stress Annealed MuMETAL Plates, thicker plate for high permeability applications

- Cryo-NETIC Stress Annealed Sheet, prototype and design ready

- Zero Gauss Chamber, our smallest three-inch diameter chamber available

Get Technical Recommendations

Our technical expertise is sought regularly for shielding material selection, design drawing reviews and tips, special technical considerations and applications. Request a technical consultation with an expert advisor by filling out our request information form and attaching any drawings or relevant documents. We look forward to serving our clients in 2020 and beyond.