For simple, affordable and accurate positioning, the EPCC electric cylinder from Festo is hard to beat. It features a high quality ball screw that has very low internal friction, enabling the EPCC to achieve higher dynamic response and short positioning times. Handling systems in particular will benefit from the weight-optimised design of the EPCC.

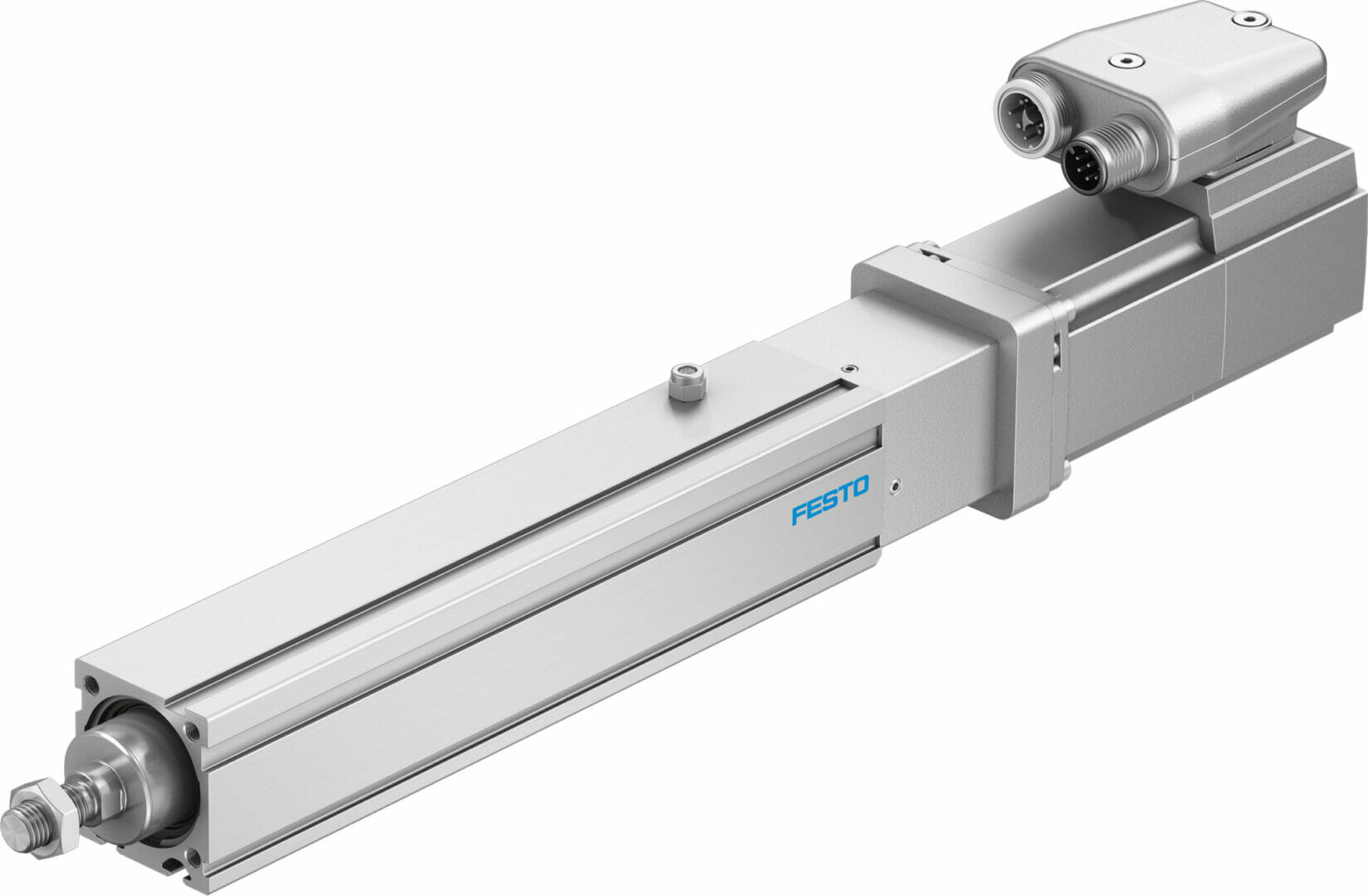

Available in four sizes, the EPCC electric cylinder comprises a non-rotating piston rod with a stroke of up to 500 mm and a plain bearing guide. The compact ball screw drive ensures quiet spindle operation and precise positioning, with life-time lubrication for a long service life. The integrated end-position cushioning reduces noise when approaching the end positions, as well as absorbing impact energy during homing.

The EPCC is designed for flexibility and offers system designers a wide range of motor mounting options for optimum integration. Users have the choice of an axial or parallel motor position, and can switch between the two at any time. Its integrated coupling and double bearing also make the EPCC physically compact. In addition, Festo’s unique “one size down” assembly principle means that the EPCC is easy to mount in combination with a spindle or toothed belt ELGC linear axis. There is no need for any additional adapters, making optimum use of space.

The EPCC also offers the option to subsequently introduce air pressure compensation using fittings and tubing. Ducted pressure compensation air offers major advantages because ambient particles or moisture are not sucked into the electric cylinder and no particles are emitted from the drive into the ambient air.

The EPCC electric cylinder has been developed as part of Festo‘s philosophy of seamless connectivity, i.e. the ability to connect a workpiece completely through to the cloud, from its mechanical connections and electrical interfaces to commissioning and controller programming. This simplifies the work of every machine builder and automation engineer when it comes to connecting the mechanical and electric technology, as well as the control levels and their interfaces with the hardware and software.