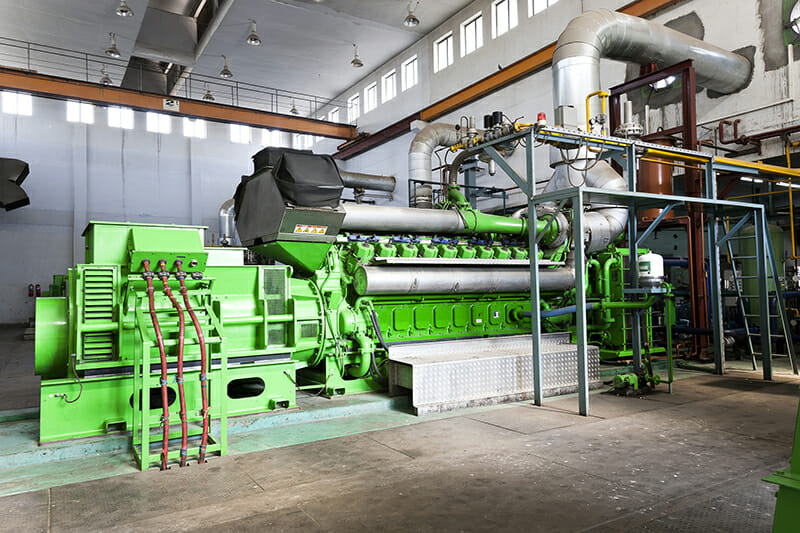

No one would argue that couplings play a crucial role in the drive train, connecting the prime mover to the driven equipment to deliver reliable and efficient operation.

Drive couplings generally go un-noticed, often operating in adverse and demanding environments, absorbing the dynamic effects of the mechanical stresses unique to their application. It is only when the coupling appears to fail, that questions are asked, and the debate begins. Did the coupling actually fail, or did it perform as designed?

In this article David Proud, General Manager of Reich Drive Systems UK, explores the two opposing points of view to determine if the coupling really is the villain, or indeed the hero of the hour.

It is true that a coupling is like many other proprietary engineering items. They are essential for successful operation, for example in the same way that a spring is within a valve, yet generally unseen and often forgotten, that is until the drive train is interrupted.

Drive couplings, when specified correctly, will operate reliably, generally with little or no ongoing maintenance, for extended periods. Once installed and running, little thought will be given to the reasons for selecting a particular coupling, or indeed the operational criteria used as part of the selection process. However, as for any mechanical item, drive couplings are designed to perform within a pre-determined operational envelope, albeit with a built in factor of safety.

If, during operation, the mechanical or environmental influences change significantly, especially for an extended period, the coupling will eventually fail. In many instances, the coupling will be seen as the culprit, however it is essential to remember that the coupling is also the “fuse” in the drive train, and the fact that it has failed may mean that it has actually saved other far more expensive equipment from significant damage.

If, and when a coupling does fail, it is essential that a detailed review of the complete drive train is undertaken to establish the true cause. It could be the case that the coupling was put under undue stress due to changes in operating conditions a result of heat, over torque, in service misalignment, higher than anticipated speeds, or perhaps the overall environment within which it has been operating has changed significantly. Any combination of these criteria could lead to the coupling operating beyond its design parameters, and whilst it was still operating it was effectively masking other potentially more serious issues.

So, in many cases, the coupling, operating as designed has acted as a mechanical fuse, interrupting the drive train and ensuring that the equipment either side of the coupling are protected from harm – the hero of the hour.

To ensure that the coupling you choose will operate as required, and importantly, protect the drive train if things start to go wrong, it is essential that consideration is given to all aspects of the application.

David Proud has also authored a series of complementary informative article covering topics such as: specifying drive couplings, the consequences of incorrect coupling selection, overcoming vibration, the costs of unplanned downtime and the effects of torsional vibration. These articles can be found on the company’s Linkedin (https://www.linkedin.com/company/reich-drive-systems-uk-limited) and Twitter (https://twitter.com/reich_uk) social media platforms.

With a history spanning over 70 years, REICH has built up unrivalled expertise in the design and manufacture of drive couplings for use across a wide range of industries and applications. The company has earned an enviable reputation not only for the quality and performance of their product range, but also for their ability to provide application and customer specific solutions through the company’s D2C (Design to Customer) philosophy.

Website – www.reich-uk.com

(Articles from Reich’s David Proud cover a series of topics relating to coupling selection etc.)