Robot systems have become an essential part of a growing number of production processes, as manufacturers leverage the capability of the robot to offer high levels of flexibility and reliability.

A successful robot system installation will deliver the performance, productivity and quality levels required to justify the initial investment, however for this to be achieved there needs to be a close working relationship and a clear understanding of expectations between the end user, the robot supplier and importantly, a qualified system integrator.

This article by Stäubli’s Simon Jenkins explores the relationship between the different project stakeholders and discusses what end users should look for when selecting a system integrator.

When the industrial robot first made an appearance, although revolutionary at the time, their functionality and capability was somewhat limited. In many cases robots would be purchased directly from the manufacturer and often integrated by the end user to perform relatively simple pick and place, handling or palletising tasks.

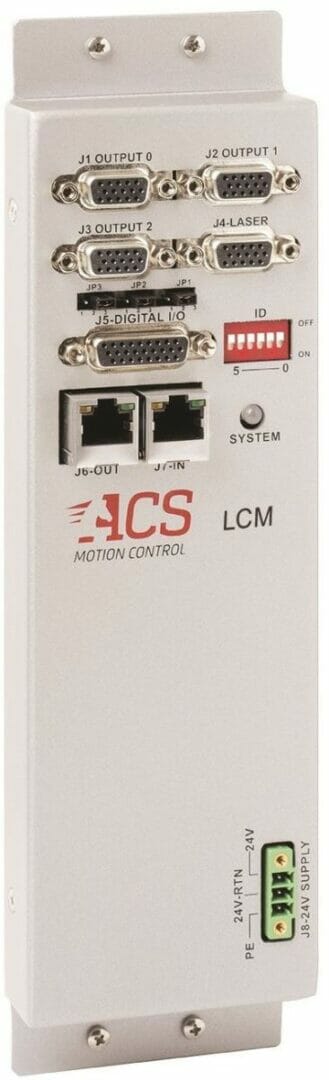

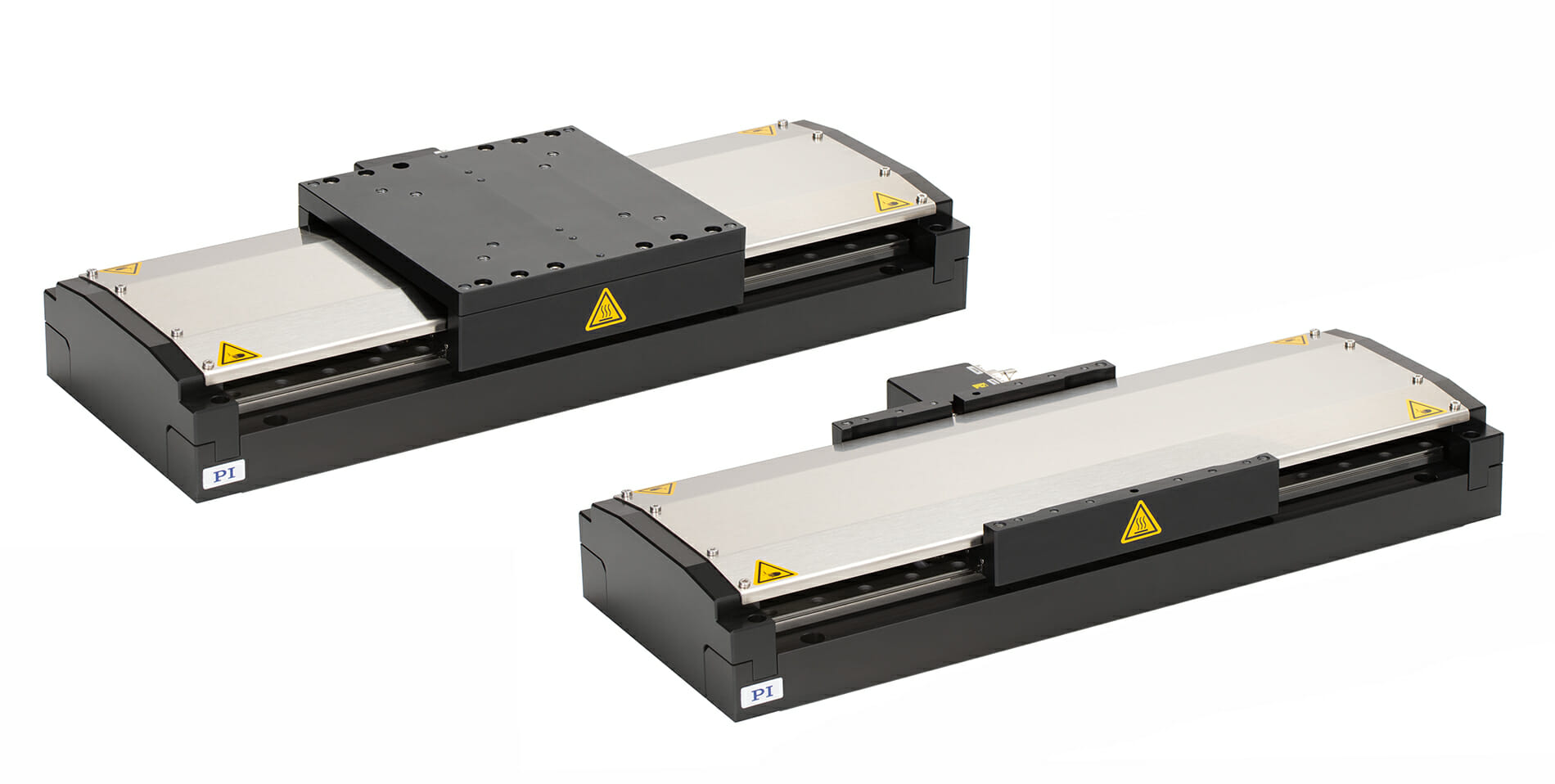

By comparison, today’s robot systems are mature, high performance production tools with a proven track record within a multitude of applications and industry sectors. The sophistication of current robot models, together with their ability to interface with other proprietary technologies such as machine vision systems and lasers etc. requires a different approach to integration if the optimum solution is to be achieved. This is where the system integrator now plays a crucial role.

However, the choice of system integrator can mean the difference between a smooth and successful project, which meets all of the specific criteria in line with anticipated project costs and timescales, and a potentially difficult and costly process. Simon Jenkins comments: “It is important that end users seek to work with a system integrator with a proven track record in their sector. This means that they will already understand the nuances of the sector and be familiar with appropriate standards and regulatory compliance measures. In addition, the integrator should ideally have previous experience of working with the robot supplier.”

Jenkins continues: “Clearly, as the robot manufacturer, Stäubli engineers are the experts in understanding how to get the most from the robot in terms of programming and performance. Therefore, our part in the three way partnership of end user, robot supplier and system integrator is initially to ensure that the correct robot model is identified to meet the unique characteristics of the application and operational environment.

We then continue to work with the chosen system integrator to fully understand the detail behind the application, identify robot features and functionality to enhance the application, and of course contribute to the generation of the final user requirements specification. From the end user’s perspective, it is essential that they clearly communicate the project requirements, objectives and goals to both the robot supplier and system integrator.”

Although the robot(s) will become part of a larger system to be built and installed by the system integrator, the robot supplier still has a key role to play in the training of operators and maintenance personnel to ensure that they get the most from the robot(s). Training by the robot supplier supports both the system integrator, in ensuring installation proceeds smoothly and that anticipated cycle times are achieved, and likewise the end user, by helping them to become self-sufficient in the operation and maintenance of the robot systems.

(Stäubli has formed close working partnerships with integrators across multiple market sectors)

Simon Jenkins concludes: “Stäubli has formed working partnerships with a number of highly respected and sector specific system integrators throughout the UK. These long term relationships mean that the integrators have in-depth experience of applying our robot systems within a broad range of often challenging and high performance applications. We will always be happy to introduce customers who may be considering the introduction of robot systems to one of our trusted partners.”