Joe Salemi, OEM Sales Manager, ZYGO

Manufacturers can be seen as vertically integrated when they have control over a majority of the value chain that extend beyond the pure production element. They are usually in the middle of this chain, and if vertically integrated, can augment their reach and influence — ultimately increasing their effectiveness on behalf of customers.

True vertical integration in the product development process for optical systems suppliers is perhaps the single most compelling competitive advantage. Customers benefit by securing access — from one source — to engineers with expertise in optical system design and engineering, metrology, component design and fabrication, thin film coating, and final assembly and test. This means that design for manufacturability (DfM) can be optimized, which enhances the integrity of end-use products, and also reduces the likelihood of time consuming and costly errors in the product development process and later transfer to manufacturing at scale.

In the world of optical systems, the key is often the attainment of extremely exacting micron-level alignment tolerances while maintaining nanometer wavefront precision. Each stage of the product development process can open up the possibility of mission creep and slippage when it comes to accuracy parameters. So, vertical integration ― with various aspects of the product development process controlled by one supplier ― and cross disciplinary teams working together on the overall process rather than a discrete aspect of it, is an exercise in risk mitigation.

Ultimately, a vertically integrated optical system supplier has a better grip on process control, typically can reduce costs, can benefit from improved efficiencies, and can manage the internal supply chain to ensure delivery predictability. The end result will have an impact on the cost and/or optimization of finished parts and systems.

OPTIMIZING OPTICAL SYSTEM DESIGN

Optical system suppliers have to attain optimized quality cost-effectively, and often to tight schedules. The key is to be able to combine knowledge and technological capabilities to produce innovative products. Equally important, they need to ensure customers introduce these products to market before their competitors ― increasing market share and profitability.

Rolling back from these goals, the importance of optimized design is vital. When looking at the entire product development process for an optical system, no meaningful cost savings can be made after the prototype production phase without damaging the quality and performance of the end product. In other words, the bulk of the cost of an optical system is determined by its design.

It is possible that a conceptual design is passed that geometrically produces a perfectly functional part. However, unless it has been assessed by experts in each stage of the product development process through to final manufacture and assembly it is likely that it will not benefit from efficiencies and cost saving possibilities that a holistic product development perspective would allow.

This once again plays to the importance of early and continuous communication between design, engineering, and manufacturing teams which is promoted by successful optical systems suppliers and is only possible in vertically integrated organizations.

PARTNERSHIP & COLLABORATION

Vertical integration is critical to ensuring an optimized customer / supplier relationship which should be viewed as a true collaborative partnership. Partnership in this context means that the customer can work in an open and collaborative way with — and draw on the experience of — experts in each aspect of the product development process, the advantages of having these experts under one roof being obvious.

An open and collaborative partnership is not so much what suppliers do but “how” they do it. To be seen as open and collaborative, suppliers have to engage the customer in direct conversation, speak clearly and frankly, and acknowledge risks and unknowns (along with the plans to mitigate).

PROJECT MANAGEMENT

Customers should seek to get a handle on how a supplier transitions products from design to manufacturing. As already discussed, the key advantage of vertical integration is that the product development team should start to get involved in the project around the time of the preliminary design review (PDR). This team should develop a parts tree, outline an assembly procedure, compose an acceptance test plan, and produce preliminary travelers to manage production data. These documents should be refined as the product progresses through design, and are then used to build prototypes and procedures, and traveler data requirements are updated to reflect what was learned in prototyping.

EXAMPLE CASE STUDY

ZYGO works with numerous customers on a variety of optical system manufacturing projects, and most of this work is confidential, so no specific insight can be given. The company does, however, have a unique perspective from which to paint an example scenario that illustrates the importance of vertical integration in project success. Due to its 50-year plus association with optical systems manufacturing.

A start-up Genome Sequencing company (NewGenCo Inc.) has just received a funding round and now has to execute on its plan to build 15 prototype instruments for deployment over the next 10 months. Optical system design is not a core competency within the NewGenCo team, yet a high performance optical system will be critical to instrument performance.

The company is working to a tight timeline, and has a board of directors looking over its shoulder, so mistakes are not an option. NewGenCo Inc. approaches a short-list of possible optical system manufacturers, and after careful deliberation and assessment of the alternatives chooses ZYGO.

From initial engagement, it becomes obvious that with ZYGO, NewGenCo has a reliable product development partner that advocates a transparent and pragmatic collaborative relationship. Right away NewGenCo is introduced to a design team that reviews and optimizes the current design to enable predictable manufacturabilty, and who would otherwise be capable to take a blank piece of paper from concept to production.

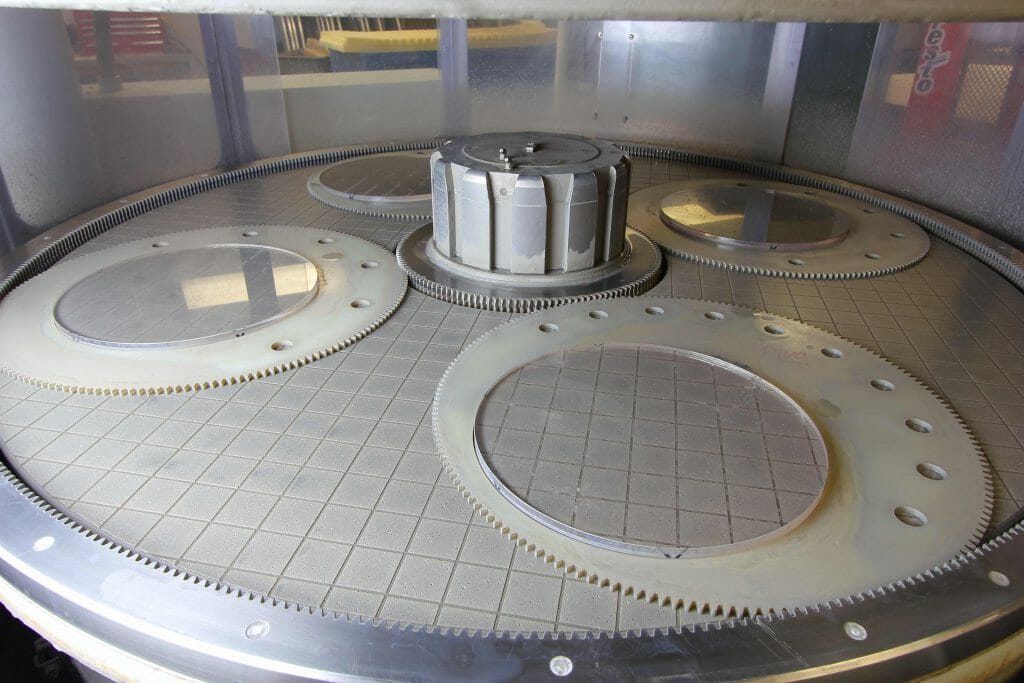

ZYGO’s Instruments business segment supports the program with custom metrology that can be trusted and will verify the optical system throughout the entire product development process.

All potential complications are negated through the use of a dedicated Technical Program Manager who ties the whole project together keeping it on track, on schedule, and on budget.

There is no better example of the enormous value of a vertically integrated optical system supplier, ensuring accurate, timely, and cost-effective optical system application development, and removing the headaches that many OEMs experience when confronted by optical system development challenges.

THE ZYGO ADVANTAGE

In addition to owning and controlling the key competencies which make for a vertically integrated optical system supplier, ZYGO also provides perhaps the world’s best plano (flat) optics through ZYGO Precision Optics; the world’s best aspheres and spherical optics through ZYGO Extreme Precision Optics; and the world’s best optical systems for NewSpace, Defense, Life Sciences, and Semiconductors through the ZYGO Electro Optics Group.

Importantly, ZYGO also has a decades-long reputation in the manufacture of best-in-class optical metrology instruments, which introduce measuring capabilities that elevate metrology from a necessary evil to a technology that can enable innovation in optical system development.

Verification and validation are an area of huge importance in optical system development, with some suppliers offering “by design” estimates or “let’s try it and see” when facing measurement challenges. Having the capability to develop custom test methods and equipment for truly validating critical specifications in-house alongside other vital competencies is critically important. As the time-worn expression states, “you can’t make it if you can’t measure it”, and the better the access to sophisticated metrology tools the better the final outcomes.