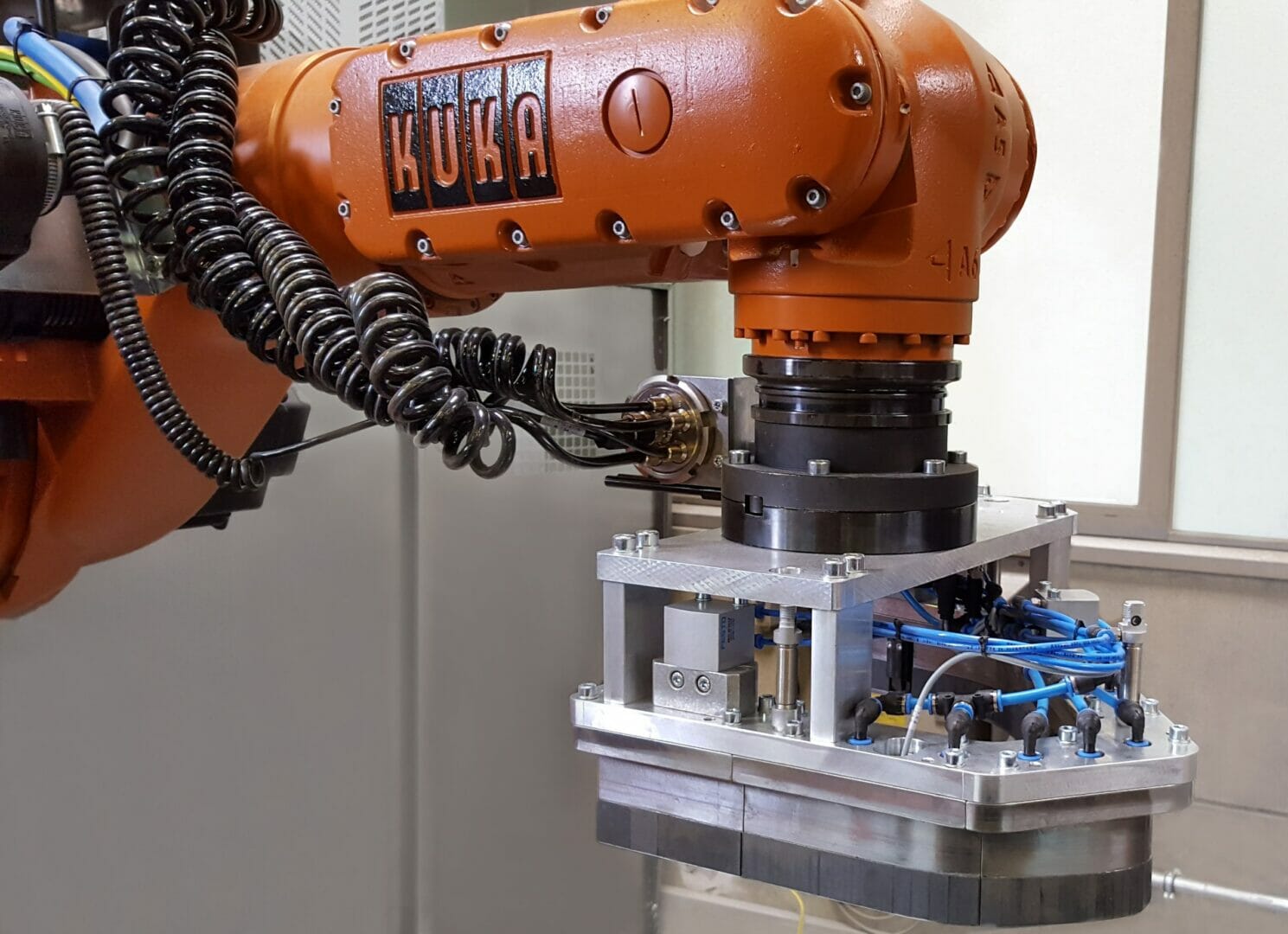

SHL AG develops and manufactures individual designed robot systems that take charge of grinding, polishing, deburring and various other services, including loading and unloading or palletizing.

While looking for the best possible connection at the interface between the pneumatic and the electrical components driving these workpiece-guided systems, SHL came across EISELE GmbH. The in Germany-based company has more than 80 years of experience with high-quality solid metal push-in connectors.

Modular kit system ensures flexibility

The Eisele MULTLINE ADAPTIVE + E is a fully modular multiple and multi-media connector with adaptive inserts. The components, which have a round base body and consist of a plug and socket, are made of aluminum and are also available in stainless steel. They are modularly designed and can flexibly integrate various tube diameters, connection types and media such as compressed air, vacuum, gases, cooling water, liquids and even connectors for electrical and electronic cables in one interface. The adaptive inserts are available in nickel-plated or dezincification-resistant brass, as well as stainless steel, depending on the medium. The push-in connectors of this innovative and flexible modular kit system are mounted virtually without tools and allow a simplified and accelerated tool and format change.

Since the middle of 2015, SHL has been pairing their pneumatically operated workpiece grippers, which are equipped with a manual exchange system, with the MULTILINE ADAPTIVE + E kit system for multiple and multi-media connectors

Photo: Eisele

SHL is particularly fond of the fact that the Eisele MULTLINE ADAPTIVE + E let them combine the electrical signals and the pneumatics in one coupling. “It is essential for our plant engineering that we can use the multiple connectors to freely combine different nominal diameters. Based on the standardized M12 round connectors, there is a wide range of possible connectors and two M12 power plugs for the electrical supply with up to 630 V. Thanks to the plug concept behind this solution, none of the conductive connections need to be soldered or clamped. To our customers, this offers a substantial savings in time as these connections can be replaced quickly if in need of service”, reveals Bernd Schätzle at SHL. It is particularly important for SHL that the tube connectors are dynamically resilient to pull and pressure so that they can withstand heavy stress during use. Overall, the multiple connectors at the front end of the robots gives a boost to the robots’ flexibility and process reliability.

Safety first – maximum system safety

The safety of SHL’s high-tech robot systems is a top priority. And this is why one property of the multiple connectors is indispensable for the design of the system: As soon as robots and workpiece gripper are separated at the interface, the compressed air supply on both sides of the connector is automatically cut off thanks to the optional shut-off function in the adaptive inserts of the MULTLINE ADAPTIVE + E. This function is very important for us, because the gripper can no longer move after disconnecting from the robot. If air were to leak after uncoupling, the gripper could move and the workpiece might come loose, potentially resulting in accidents”, details Bernd Schätzle.

Precision, good workmanship and maximum reliability – these are the qualities that convinced SHL.