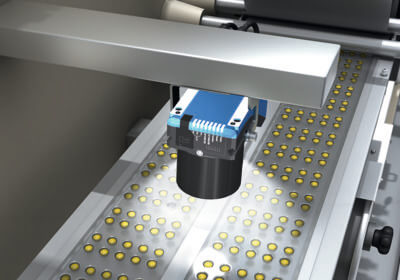

The TRS Engineering TechModern® Presses have been designed and developed to produce sheet metal and tube formed parts for aerospace; automotive and general engineering products for Tomorrow’s World. They introduce leading edge technology to enable panels and tubes to be developed to their optimum configuration using a computer on-board the press.

The on-board computer can be equipped to perform the comprehensive sets of engineering functions including the press operations as well as the component design and stress simulation and condition monitoring of the press in operation from anywhere in the world.

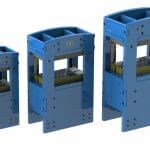

The Frame and Press assemblies, being of “flat pack and modular” construction, can be transported direct to the customer’s facilities, without the special wide/heavy load problems, associated with conventional presses of the same size, and assembled on site. Assembled, that is, onto an engineering workshop floor without foundations and fitted with its operating modules from floor level, obviating the need for high rise assembly platforms

They can be adapted to suit various configurations of component shapes, sizes and functional requirements and used for Hydroforming; Stamping and Deep Drawing.

Hydroforming uses fluid pressure to form the components that would otherwise be stamped and welded. The process offers a range of benefits including reduced costs and improved quality (more info in attachment “TRS Engineering TechModern®Presses for Tomorrow’s World”)

The Hydroforming processes were initially developed in the mid-1950s but did not become a widely established process in the UK, with some notable exceptions including in Newton Ayliff, County Durham in the mid-1980s. They were initially sparsely adopted in Europe, the USA and Far East and hydroformed products had been imported from these countries to the UK mainly at premium rates.

Increasingly the economic penalties to the UK balance of trade, of having to import Hydroformed parts for their superior quality, became apparent and detailed studies by TRS demonstrated that these could be reversed by applying leading edge technology and methodology to the processes.

So called hydroforming presses were often converted from hydraulic press designs and had limited versatility and

the need for a new generation press design, adopting computer software and eliminating the intrinsic difficulties present with the converted mechanical and hydraulic presses, became increasingly apparent.

Translating these needs into practice resulted in creating a new generation of presses which exceeded expectations to the point that the techno/economic advantages were in the presses themselves rather than in the formed products they make.

Overseas competitors have been eager to discover what TRS has been developing and it has been necessary to keep a low profile until the new press’s functionality could be demonstrated.

The origins, the history and the capabilities of the company + future plans/expectations

A comprehensive description of TRS Engineering is given in www.trseng.com

The Bloxwich based engineering company was established in England, within 5 minutes driving time of junction 10 of the M6 motorway in 1993, putting it within easy access to the road network and as a result of a lot of hard work put forward by the founders, the company has survived the industry trends and grown to what it is today.

The company was initially formed as a Jig & Tool making firm for motor industry. But the gradual progression of the company has seen it mastering the areas of Designing, Precision Engineering, Precision machining, Reverse Engineering, Prototyping, 3D Laser Cutting & Welding Services, Presswork and many other aspects of precision engineering.

The adaptable nature of the firm has taken it forward through hard times, along with an unmatchable level of dedication and commitment offered by the vastly skilled workforce. The awards won by TRS engineering over the past years is a real testament of their true commitment for providing highly innovative engineering solutions to its customers