Fasteners have been used in panel applications for many years to fix panels together or to fix other components to panels. Very often, during removal of the panel, the fastener breaks or worse still, the panel is damaged.

Following the introduction of legislation increasing automotive manufacturers’ responsibility for the end-of-lifetime disposal of their products, JET PRESS has increased their range of parts where disassembly for maintenance or disposal is designed into their function.

The End-of-Life Vehicles Regulations states that a vehicle producer is required to make a convenient network of facilities available for dismantling and recycling; end-of-life vehicles can be taken to one of these facilities at no cost to the final owner. These facilities make sure that end-of-life vehicles and their components are disposed of in an environmentally-friendly way.

Previously fasteners were often a one use ‘fix and forget’ solution, but now the emphasis has been put on reducing environmental impact through easy and low cost disassembly.

An important additional virtue of these reusable fasteners lies in the time and money that can be saved where regular disassembly is required such as access of panels for maintenance.

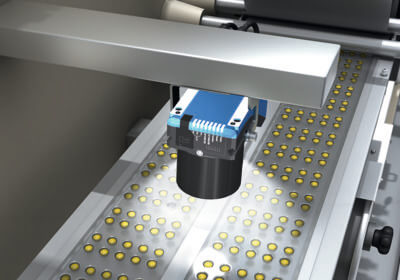

As well as holding a vast stock of standard fasteners suitable for easy assembly and disassembly, bespoke solutions are also in demand. JET PRESS recently designed and manufactured a two-part fastener solution in heat-stabilised nylon for use in the German automotive industry. A key customer requirement for this under-bonnet application was for specific push-on and pull-off forces for maintenance access. 3D printed prototypes served to quickly offer proof-of-concept before full production.

Andrew Mitchell, Sales & Marketing Director for JET PRESS says “We have a range of parts that have been designed with disassembly in mind. These have been designed for easy placement and removal of panels without destroying the panel or the clip. They can be used time-and-time again for effortless fixing of panels or components to panels”.

The standard range includes Plastic Trim Panel Fasteners, Fascia and Trim Panel Clips, Scrivets, Removable Plastic Rivets, Quarter Turn Fasteners, Weld Stud Cable & Pipe Clips and Ratchet Style Quick Assembly Nuts.

JET PRESS is committed to conducting business in a manner deemed ethically and environmentally responsible. To achieve this goal they have developed an environmental management system that meets the requirements of ISO 14001:2004.

To find out how fasteners designed for quick assembly and disassembly can help your business, please contact JET PRESS on 01623 551 800 for advice and free samples.