“As soon as you open your mind to doing things differently, the doors of opportunity practically fly off their hinges.”

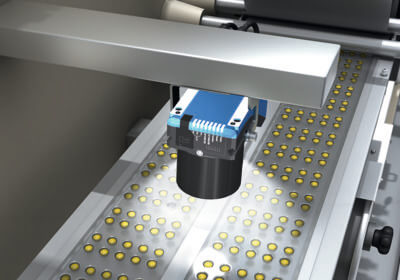

Low profile or irregular shaped workpieces present a familiar set of challenges to engineers. Will it provide maximum holding force with little such little grip? Can we machine the face of the clamp to suit the workpiece? Do the clamps restrict access? Will they damage small delicate workpieces?

Hillcliff’s extensive range of low profile clamps provide the opportunity for engineers to find quick, easy and economical answers to these questions. Using a new system of clamping could make for a better system and so maximise your machining time.

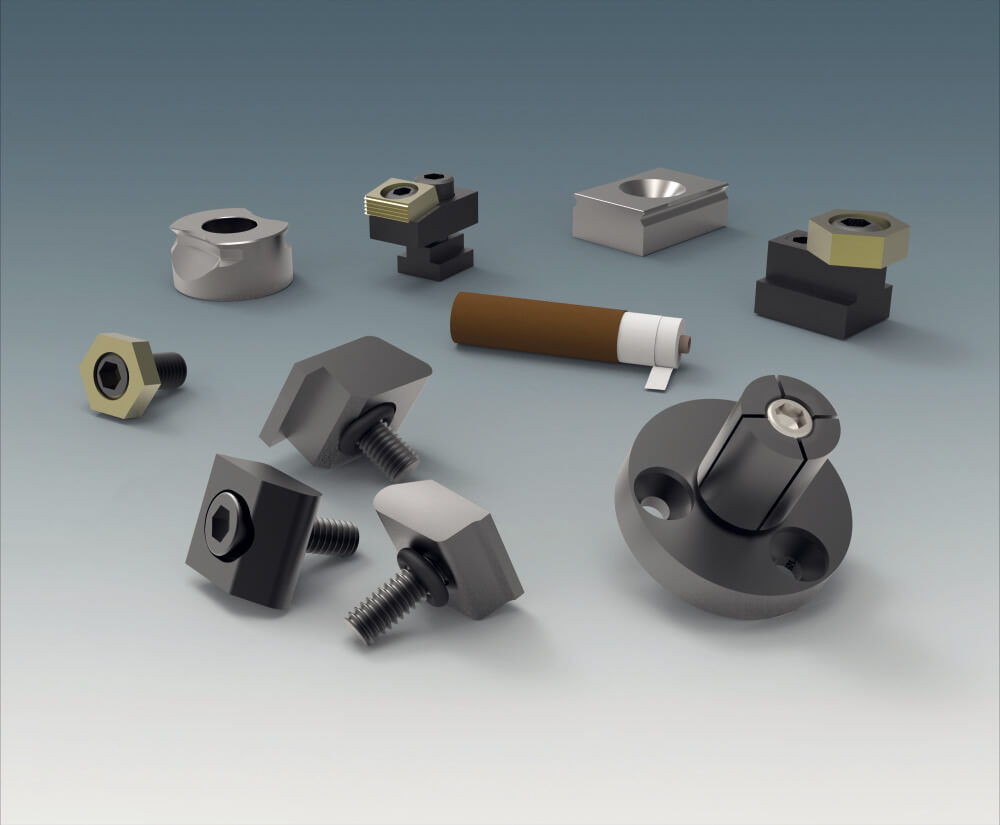

The Pitbull clamp is a revolutionary fixture clamp that is ideal for aggressive machining. This low profile clamp provides positive down force with holding forces up to 50kN. The tool steel blunt edge is less likely to mark work pieces, whilst the knife edge version bites into the work piece for more grip.

Talongrip clamps are often used in conjunction with the Pitbull clamps, they allow for aggressive clamping on as little as 1.5mm. The Talongrip clamp has a further option to increase your functionality of your 100 and 150mm vices, a simple bolt on system that allows you to perform aggressive machining.

Our mini finger clamps use a unique three finger setup ensuring components are both pulled down and clamped in the same motion. The face of the clamp is made of three parts or fingers, two outer flexible fingers for pulling down the component to the work table, and one solid central finger, or clamping stop; to provide side hold force.

The Fixture clamps are the ideal solution for multiple part clamping, with their hex head, using a cam action to provide strong and fast work holding. There are two options of fitments dependant on the situation, one using a tapered screw and the other using a t-nut for machine beds.

The compact, economical Uniforce clamp holds two parts with an equal clamping action. There is a machinable option available that has extra material on the clamp jaws, this allows for the face of the jaws to be machined to suit the workpiece.

For more information on any of these products or if you would like to request a free comprehensive catalogue showcasing the whole ranges, send an email to info@hillcliff-tools.com or call us on 01483 266780.