Leading global manufacturer of fastening solutions, Atlas Copco, has launched a pioneering range of ‘Low Reaction’ (LRT) tools.

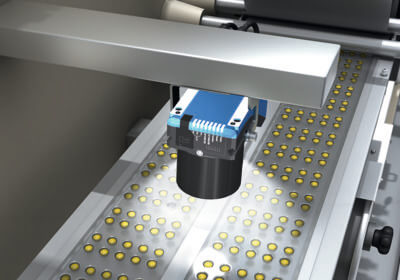

The new line-up of battery and DC-powered tools has been developed specifically as part of Atlas Copco’s Smart Connected Assembly concept, to improve both operator ergonomics and factory optimisation.

This includes a Transducer Battery Pulse (TBP) based tool that features a hydraulic pulse unit rather than gears and an oil-filled chamber, enabling higher torque of up to 55Nm with vibration levels below the minimum standard. Delivering five million pulses before maintenance is required, operating performance is up to five times longer between service intervals.

For applications involving hard joints, the integration of Atlas Copco’s TurboTight® torque management technology means that the tool, rather than the operator, absorbs the reaction force. Designed to avoid operator influence, the new range of tools also features Atlas Copco’s TrueAngle® technology, which uses a gyro signal to read operator movement, thereby increasing the accuracy of angle readings and improving controlled tightening, as well as avoiding damaged threads, re-hits and premature shut-offs.

David Embley, General Manager, Atlas Copco Tools UK, commented:

“Our customers are seeing increasing complexity in their product mix and demands for higher quality. A batch count of one is quite typical in today’s world of choice, so to compete, manufacturers need to produce the best quality at the lowest cost, in the quickest time. The goal is zero defects and full traceability, along with better agility to face the challenges of globalisation, new technologies and competition.

“At the heart of Atlas Copco’s Smart Connected Assembly is a focus on achieving quality, productivity and traceability in complex assembly processes. Advanced tooling, software solutions and error-proofed production meets the needs of our customers in a digital world. Low reaction tooling is a key part of our vision and process control and data driven services add to the mix to equip businesses with the solutions they need. We look to maximise productivity and increase customer efficiency, whilst reducing human error and ensuring operator safety. Our customers need tangible return on investment, which is why we introduced our six pillars of value.

Atlas Copco Low Reaction Tools