Pumps are an essential part of many food processing lines: not just for liquids, but also viscous materials such as spreads and dips, and materials containing solids such as fruit and vegetable mixes. Using the wrong pump can have expensive consequences in terms of both potential damage to products or equipment, or higher than expected energy costs.

A good pump needs to meet the requirements of the product, as well as normal food handling hygiene requirements, such as Clean-in-Place (CIP). There are many types of pump, but not all of them are capable of maintaining product quality at a reasonable cost, plus maintain the required pressure in the system. These challenges resulted in the production of the BP Series of piston pumps from HRS Heat Exchangers, which have been proven in hundreds of food processing environments handling everything from peppers, strawberries and baby carrots to sauces, dips, fruit purées, and many other products.

A positive solution

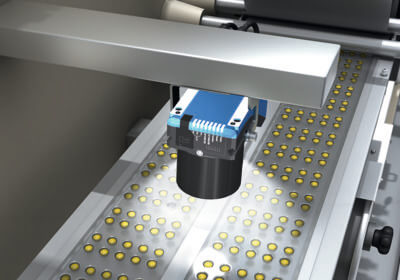

The HRS BP Series is a purpose-designed reciprocating positive -displacement pump, with an expanding cavity on the suction side and a decreasing cavity on the discharge side. Material flows into the pump as the cavity on the suction side expands and is forced out of the discharge side as the cavity collapses. The BP Series features a hygienic design which incorporates a separator fitted between the piston and the hydraulic chamber to ensure that there is no contact between the product chamber and the hydraulic oil. Once the pump is in operation, no part which comes into contact with oil comes into contact with the product.

The standard BP Series has an adjustable flow rate between a minimum of 200 litres/hour and a maximum of 12,000 litres/hour, and features a high pressure drop of up to 30 bar. It is suitable for a wide range of high viscosity, shear sensitive and large particle-containing fluids. Clap valves allow pumping of whole fruits or vegetables, and an alternative piston pump with a pneumatic cylinder can be supplied for low pressure applications of less than 5 bar.

Multiple production lines, one pump

Following the success of the standard BP Series in a range of applications, HRS Heat Exchangers are pleased to have developed two variants. The first of these is the BPM Series, a mobile version of the standard BP Series pump. This is mounted on a mobile skid unit for easy movement, allowing it to be used across multiple production lines and locations, something which is increasingly popular with food manufacturers producing short runs of specialist products. Thanks to the new BPM Series, companies can enjoy the benefits of a BP Series pump across multiple production lines without the need to invest in a dedicated pump for each line, resulting in considerable capital savings.

Viscosity no problem

The second addition to the range is the BPH Series. This has been specifically designed for highly viscous products, such as hummus, and especially those which are produced and packed at low temperatures.

Matt Hale, International Sales and Marketing Director at HRS Heat Exchangers, explains: “When dealing with highly viscous materials, particularly at low temperatures such as hummus at 5 deg. C., the product’s thickness can make it hard to prime the pump when starting production following cleaning. The new BPH Series overcomes this. It uses a gravity-fed hopper, together with a screw conveyor, to initially push product into the body of the pump. Once the cavity on the suction side has been filled, the pump is primed and will then operate as normal with a constant stream of product.”

With the addition of the BPM and BPH Series of pumps, HRS Heat Exchangers are now able to offer an increased range of pumping solutions for a variety of uses in the food sector.