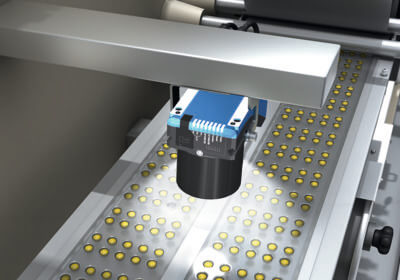

Wave and Reflow Soldering are huge parts of the PCB industry. The only reliable way to get your circuits to stick to your board and stay there is by soldering them on. Without soldering, there are no printed circuit boards.

There are two main types of soldering for PCBs: wave soldering and reflow soldering.

Soldering successfully can be hindered by the presence of oxygen as it increases oxidation and therefore spoilage, especially if there’s any presence of moisture in the environment that would spark the corrosion reaction. The solution to this problem is to introduce nitrogen gas, a safe, dry and noncombustible gas, to effectively displace oxygen and create an environment that is much more conducive to soldering.

Titan N2 provides a wide range of nitrogen generators that are ideally suited to this application and are used across the industry with great success. Integrated oxygen analysers with alarm function and shut off features alert you to any potential purity issues and ensure that purity is never an issue in your manufacturing cycle.

Our process simply removes oxygen from standard compressed air, leaving you with a supply of dry, high purity nitrogen with consistent purity. Using PSA (Pressure Swing Adsorption) technology for this process, our products offer reliability and low service costs with a typical lifespan in excess of 10 years.

Generating your own supply of high purity nitrogen on site and on demand, means there’s no need to rely on third party gas companies or be subjected to unexpected price increases. Payback is typically within 18 months of initial purchase making ROI an attractive incentive when considering your options. There are no health and safety issues, no cylinders to move and change and no liquid nitrogen deliveries to worry about.

For further information on our nitrogen generators, contact us today.

+44 (0) 333 2000 502

info@titan-n2.com

www.titan-n2.com