Smart fridges, agricultural drones, or industrial robots – the working prototype and the first image present special challenges for developers embedding bare sensors into their devices. In this case, small sensor modules can both simplify and accelerate the process to a working prototype, providing the first image to smart devices in only 60 minutes.

The manufacturer of a fridge must have experience in refrigeration. For smart home appliances, it is no longer that simple. A modern fridge with integrated cameras can analyze the food; update the online shopping list; or, display suitable recipes. Developers of these smart devices need basic knowledge about imaging, sensor technology and the integration of camera technology into the refrigerator.

Initial integration of vision technology into smart devices often poses new challenges to development teams. They must realize a prototype; the basic functionality and the interaction of all components must work flawlessly. In the vision subsystem, a wide variety of components must be connected and verified. Electronic design, layout, and PCB production take time and resources. In particular, high-speed signaling and sensor connection require in-depth specialist experience. A lack of knowhow can prolong the timeline extensively.

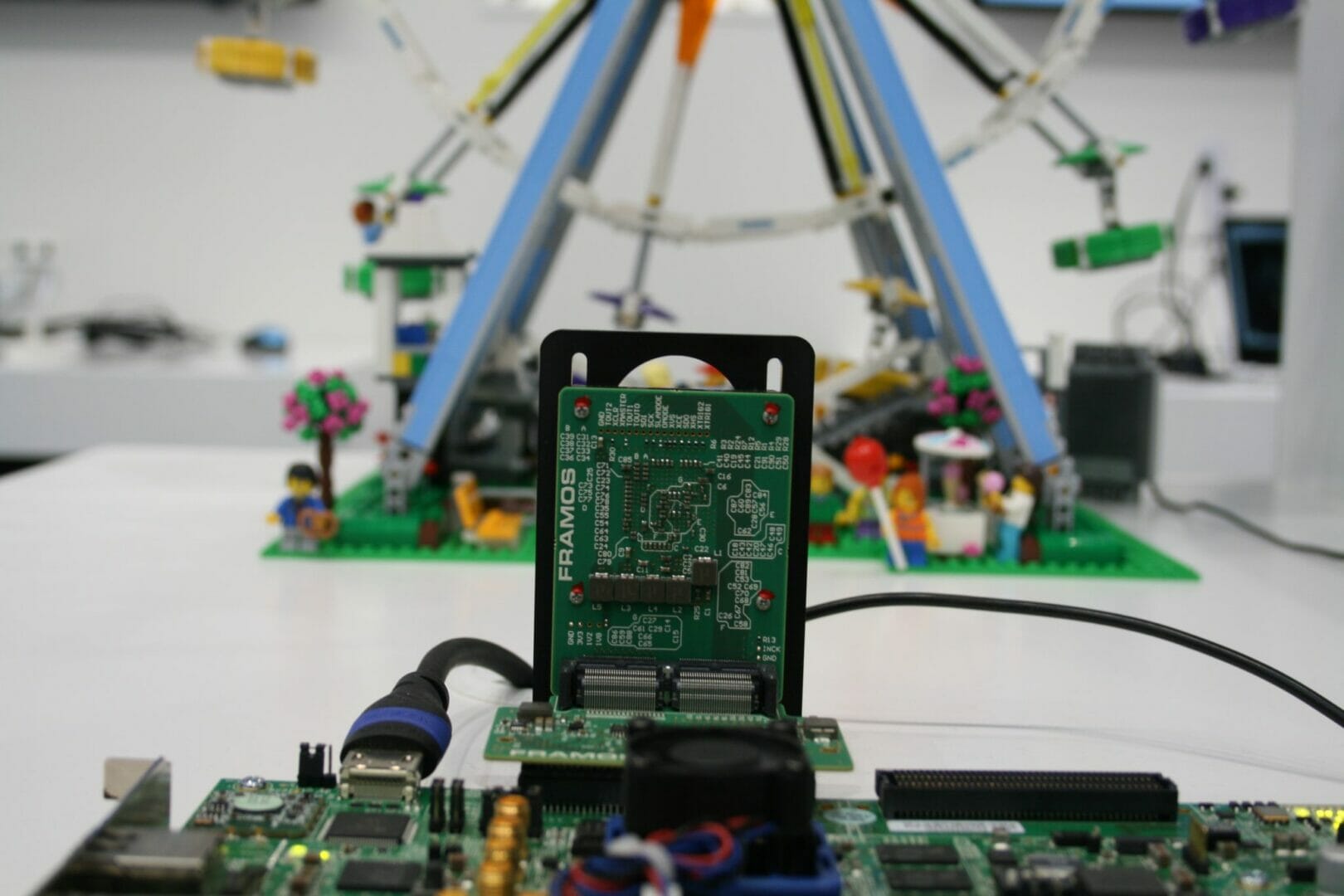

“We want to enable developers to qualify image sensors directly in their application, integrate them quickly and not have to worry about the basic vision technology,” says André Brela from FRAMOS. The company’s product line of interchangeable sensor modules and adapters facilitates the development of embedded vision products. According to Brela, developers that work with vision for the first time can implement initial prototypes with standard components, without a great deal of specialist knowledge. The product manager says that “it takes less than 60 minutes from unpacking the pre-soldered sensor modules to capturing the first image”.

Sensors and processors with a flexible adapter concept can be exchanged during testing to identify the best combination without affecting the interfaces. The software developers can operate independently of the hardware team. “With our sensor modules, OEMs and device manufacturers do not necessarily have to become sensor experts themselves,” says Brela. “We believe our customers are most successful when they concentrate on their core application, like producing really good refrigerators.” For the smart additional functions, the FRAMOS Embedded Vision product line offers immediately accessible hardware and drivers that combine a wide variety of image sensors with open processing platforms. It presents image processing to newcomers the chance to have the first prototype of a smart refrigerator up and running in a short time, and at low cost.