We have been developing industrial control systems for many years now, continually staying ahead of the curve by embracing new technologies and applying best practice. Our award-winning ‘digital engineering’ approach here at Trant Automation Control & Technology (ACT) has reaped considerable benefits for clients who rightly expect best-in-class solutions for mission-critical infrastructure.

For example, we are now only one of two companies in the UK able to machine, assemble and certify explosion-proof (EX) enclosures for hazardous environments.

It is testament to Trant ACT’s in-house expertise that we have secured full partnership with Technor Marachel, a first-class supplier of EX enclosures and equipment, giving us the ability to complete projects in just a few short weeks, rather than months.

We have gone from strength to strength in other areas as well, winning large orders in the water, oil and gas, process automation, nuclear, energy and pharmaceutical sectors.

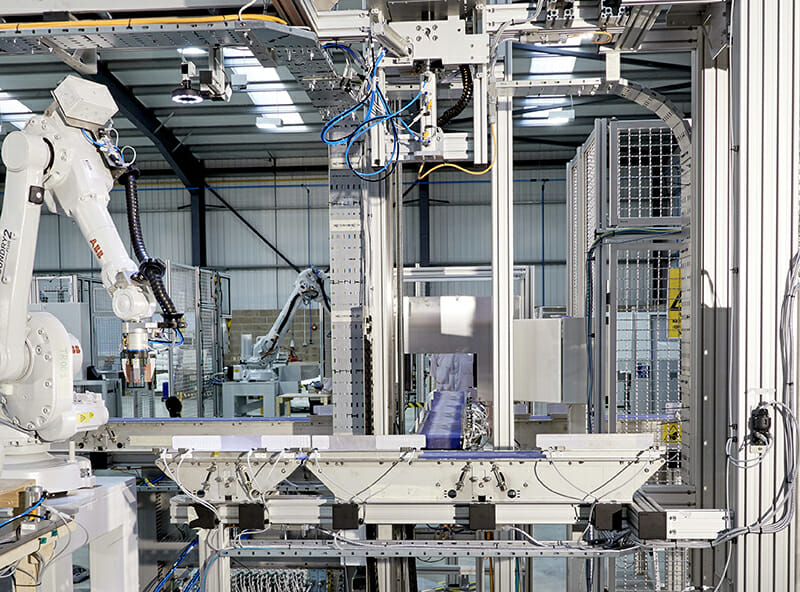

Dealing with all aspects of design, build and testing of automation systems, we are able to create bespoke solutions for all types of industrial automation.

We specialise in control panels, from small bespoke pumping station panels, controlled by relay systems, to large-scale motor control centres, controlled by industrial controllers and graphic user interface.

With our in-house software development team, we can configure a range of PLC, HMI and SCADA equipment from manufacturers such as Rockwell Automation, Siemens, Mitsubishi and Schneider.

The ability to keep both the manufacturing and software development under one roof gives Trant ACT a major competitive advantage.

In addition to our industrial software development capabilities, Trant ACT has also branched out into the world of 3D simulations.

This enables us to simulate entire plant environments and equipment in full 3D, with complete interaction with PLC systems.

Even more exciting than this however is our ability to render these 3D environments in virtual reality at our dedicated VR facility.

From visualisation of projects prior to build, to HAZOP investigations, training and even remote site visualisation and operation, the possibilities for this new technology are endless.

Stuart Rice, General Manager of Trant ACT, said: “These are exciting times are for the company, with a sustained increase in staff, a substantial increase in orders and an extensive tender book.”

For more information about Trant ACT, part of the Trant Engineering parent company, and the products and services that it can provide to solve your industrial automation needs, please contact [email protected]