Embedded vision is an important driver of digitization and automation. Many manufacturers and companies can make their products “smart” with Embedded Vision through visual sensors, or for automating their production processes. Seeing robots, drones, and autonomous assistants, help industry to become more competitive. Smart devices, or AR/VR applications open new, high-potential consumer and industrial markets.

The development of products and solutions with Embedded Vision must be fast and efficient; and, be cost effective for companies to fully exploit these competitive advantages. Therefore, many companies and OEMs work with components and suppliers from the Far East. However, this approach also poses challenges. Often, customers complain about inadequate communication; the prolonged coordination of details; delays in delivery; and, poor quality. In particular, various expectations of the product, quality, and ease of integration appear to exist.

In practice, Embedded Vision requires sufficiently flexible and versatile evaluation platforms. Customers need integrated sensor and optical solutions, testing platforms, suitable IP, and technical support. In addition, they require advice about configuring their machines to “see”. Other reported examples are poorly developed drivers, or insufficient documentation. These problems hamper fast and efficient vision development, and generate additional costs.

This situation is particularly difficult for customers with strengths on the system side, or working with Embedded Vision for the first time. Other companies do not have the time or resources to delve deeper into vision development. Subjectively, personal service and technical support often do not seem to exist from China or Taiwan, or that customer service is restricted only to high-volume customers. Therefore, medium-sized companies miss an opportunity to forge a direct relationship with the supplier, and consequently complain about catalogue sales without technical support.

The question is; how can embedded vision products be developed quickly, with high-quality and be cost-effective with local partners? Here, FRAMOS is able to help customers realize a custom vision solution with direct support and competitive prices, with both local and offshore production capabilities. Ultimately, by providing maximum flexibility, the solutions are achieved faster and are more favorable to customers – a similar outcome is true for smaller quantities, resulting from clear communication and effective project management from the top on down. Customers can eliminate the potential drawbacks of working with suppliers from Asia, and still get a competitive price.

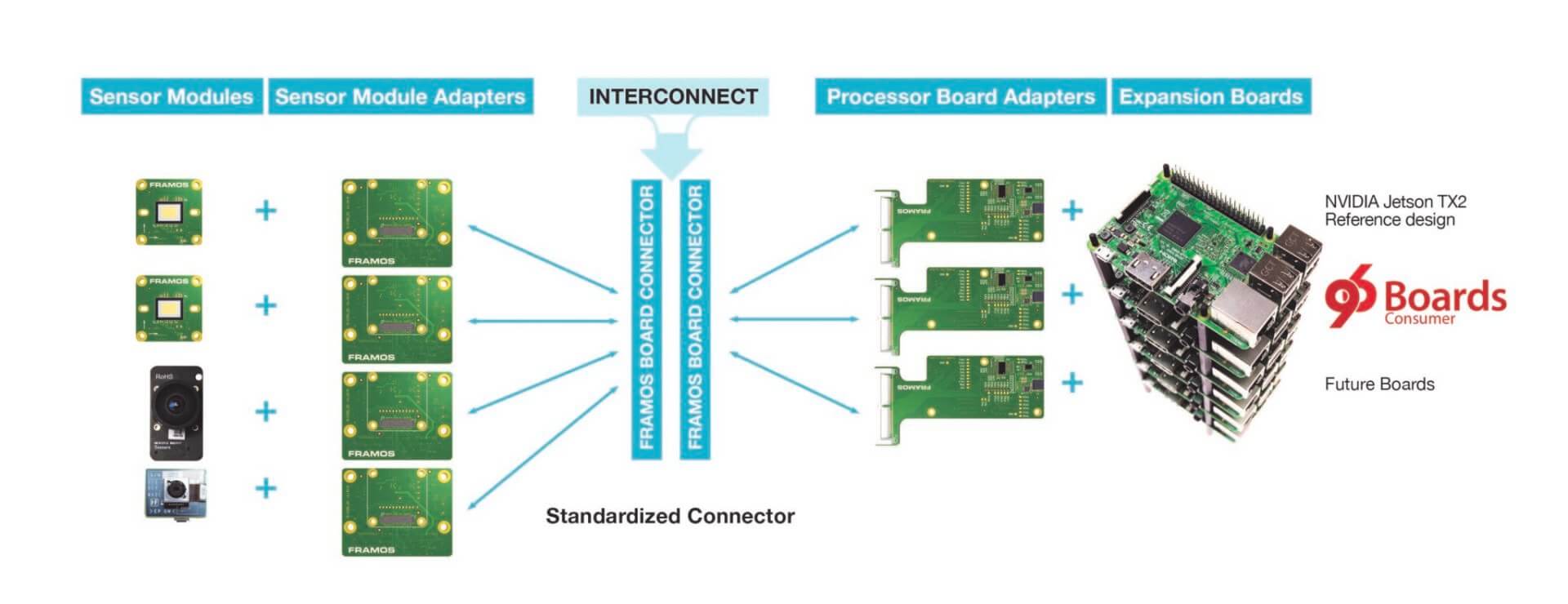

Superior technical development helps to solve this balancing act: FRAMOS has developed a broad range of sensor modules and adapters that complement each other. They provide a direct connection to all common processor platforms for Embedded Vision. The costs for prototyping, testing, and the integration of imaging into products up to series production are significantly reduced. Customers can rely on the vision experience of FRAMOS and local partners; concentrate on their core business; and, conserve their own resources. In addition, they reduce material and development costs, and concurrently benefit from a shorter time-to-market. Consequently, new and future sensors can be quickly designed-in for innovative embedded vision solutions – predictable results with no technical surprises.