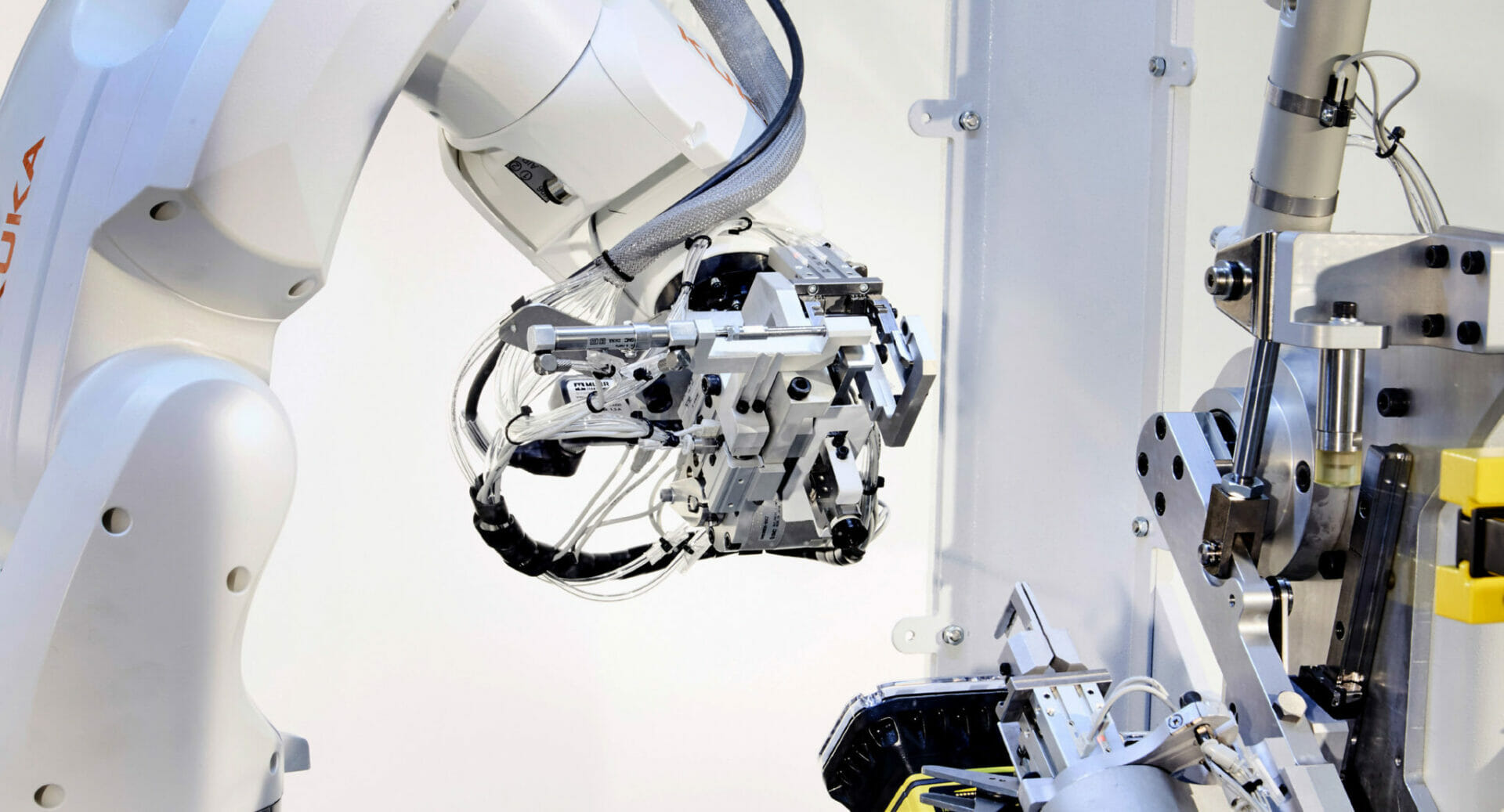

Electric linear drives are replacing conventional pneumatic cylinders in more and more applications. The reasons include poor efficiency, high costs for commissioning, reconfiguration, service, and maintenance, and the limited control capabilities of pneumatic systems.

Although pneumatic drives have a lower initial purchase cost than that of a linear motor, their on-going energy and service costs are much higher and their long-term life is much shorter. They also need constant maintenance and adjustment to maintain process stability.

The linear motor also offers a much simpler solution when considered as a complete system.

As a leader in the development of high performance linear motors, LinMot have been offering simple to install cylindrical linear motor with a single cable connection. More recently they now offer even simpler option of a combined drive and motor, only requiring a cable connection directly from the PLC to the motor drive.

The electric linear motor also offers much more flexibility with smooth and very fast programmable motion. This offers improved production stability and monitoring and lower product waste costs. Typical performance is for example is achieving a 400mm stroke in less than 300ms, consuming less than 200W. This can be achieved with total repeatability with very little noise, low maintenance and no adjustment needed.

Energy and running costs can be even more important and an analysis of the investment and energy costs over their service life, shows that industrial linear motors from LinMot can pay for themselves within a few months or even weeks, even in simple point-to-point motions between two positions. For example, moving 400 mm with a 15 kg of mass in motion, operating at 30 cycles per minutes and 50% duty cycle (= 2,000 ms cycle time) shows that the savings from the use of an industrial linear motor, compared to the use of a pneumatic cylinder, are 2,300 EUR and 5,900 EUR at 12 and 24 months of service respectively.

What may not be immediately realised is the increased lifespan that is possible with an electric linear motor. With no seals and smoother motion, hundreds of millions of cycles of operation can be achieved with complete repeatability during the lifetime.

In summary, for linear motions in many applications, the very efficient, all-purpose electric linear motor in tubular form is a good substitute for pneumatic cylinders.

For more information, please contact Quin Systems, the UK LinMot distributor on 0118 977 1077 or sales@quin.co.uk. Website: www.quin.co.uk