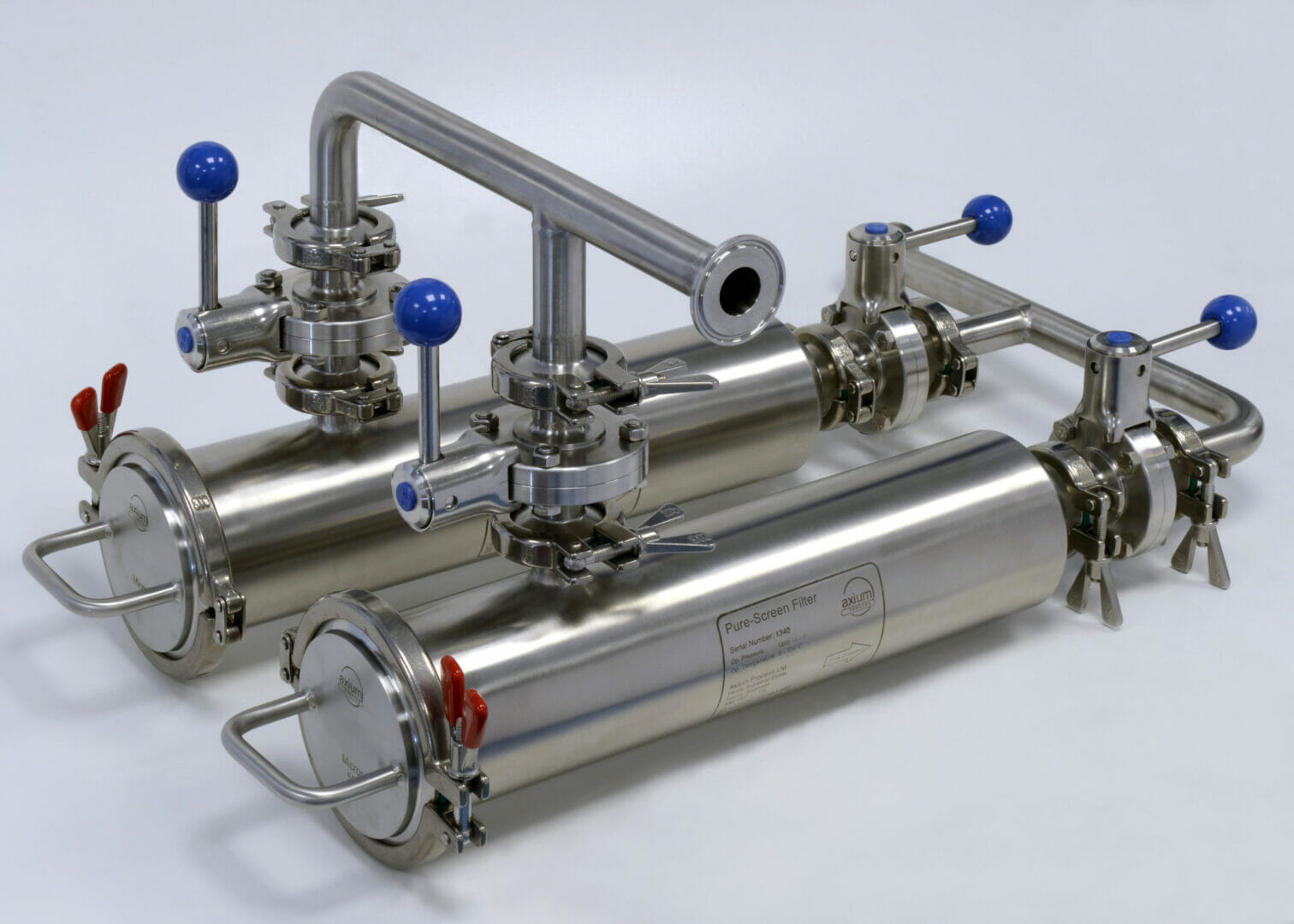

Axium Process has developed its range of hygienic stainless steel filters ensuring ease of use, simple maintenance, dependability and outstanding quality is at the forefront of its design.

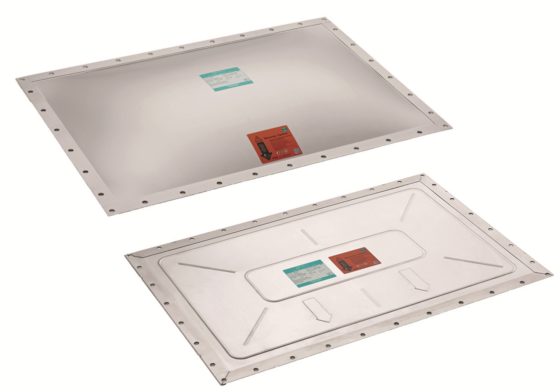

The standard filter range is available with short delivery times in order to meet customer demand and has a 90 degree or in-line housing option with fully interchangeable and replacement elements. The elements, which can be safely removed without specialist tooling, cleaned or steamed in place and quickly put back into service reducing unnecessary downtime, are available in wedge-wire, sintered mesh and perforated tube providing a filtration range from 5 microns up to 8000 microns.

Axium’s filters provide a reliable solution for critical applications such as a pre-filter for pumps or debris capture for CIP. The popular wedge-wire design is widely used for applications where product consistency and smoothness is essential and for powder dispersing applications.

The sintered mesh screen is ideal for high or low-temperatures and is used in the pharmaceutical, food and beverage industries for the removal of suspended solids, micro-flakes, fibres and for glass contamination prevention. For process security duties or coarse filtration applications, the company’s perforated tube screen provides a robust and flexible solution.

When more complex filtering is required, Axium’s innovative filter systems can provide improved process efficiencies and substantial cost savings by reducing downtime, maintenance and screen renewal costs. The filter’s robust construction enables automatic or manual backflush facilities which can be fitted to the filter without fear of damaging the elements.

Axium’s filter systems include duplex, triplex and multiplex options and are engineered to give a small footprint, high flow rates and substantial dirt holding capacity. Systems can be customised with support framework, sample points, drainage, vent valves and pressure gauges.