Explosion safety covers a broad range of applications. Following our first part, this article gives you an idea of important explosion safety precautions.

Depending on the results of the hazard and risk analysis, a number of proven precautions need to be taken. They are divided into explosion prevention and explosion protection. Preventive precautions are designed to prevent an explosive atmosphere and therefore to reduce the probability of an explosion. Protective precautions involve reducing the impact of a possible explosion to a more moderate level, so that the resulting damage is less severe. This includes conventional venting through the use of explosion vents, flameless venting, explosion isolation and explosion suppression. This kind of explosion safety is a vital necessity in virtually all plants.

As protective precautions are of such high relevance, we shall briefly outline the most common safety systems at this point:

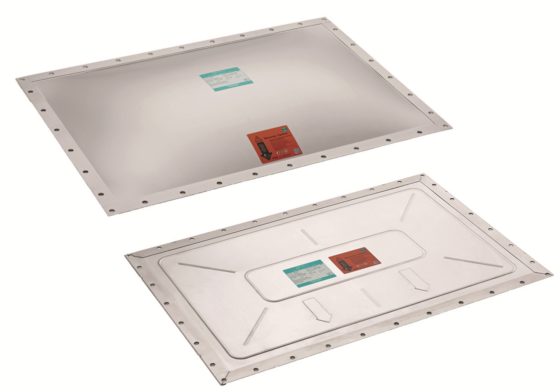

Conventional venting through the use of explosion vents

If a plant is situated outside buildings or if parts of a plant are next to an outer wall, one frequent safety precaution is to install explosion vents. If an explosion occurs, the explosion vent protects the system by opening. This reduces any overpressure within the vessel, and the explosion is released to the outside. As virtually no processes are the same, there are numerous types of explosion vents which differ in shape and material and also in their resistance to temperature, pressure and vacuum.

Flameless venting

If a plant is situated within a building, however, explosion vents are not suitable for pressure relief purposes, as the safety area around them is inadequate to relieve the emerging dust and flames.

Flameless venting is an option that is economical and effective. Let us have a look at one particular technology at this point: The special mesh filter that is used in a Q-Box, Q-Ball or Q-Rohr efficiently cools down any flames, preventing both flames and pressure from emerging and ensures particulate retention. The typical increase in pressure and noise is reduced to an almost imperceptible minimum, thus protecting both humans and machinery.

Explosion isolation

In a production facility the individual parts of the plant are always connected by pipelines. The purpose of explosion isolation is to ensure that the pressure and the flames cannot propagate and so that any adjoining parts of the plant are protected. A distinction is made between active and passive isolation systems.

An active system is alerted to an explosion at an early stage, when an explosion begins to develop. Passive isolation, on the other hand, responds purely mechanically to the spreading or loss of pressure. This also applies to explosion valves. Under normal operation an explosion valve in a pipeline is kept open by the available flow. When an explosion occurs, the valve is closed by the spreading of the pressure front, thus effectively preventing the pressure and the flames from propagating any further.

Explosion suppression

It means eliminating the explosion at its very onset. A highly effective extinguishing agent is released within milliseconds, nipping the explosion in the bud straightaway. If required, an explosion suppression system can also be used for explosion isolation purposes.