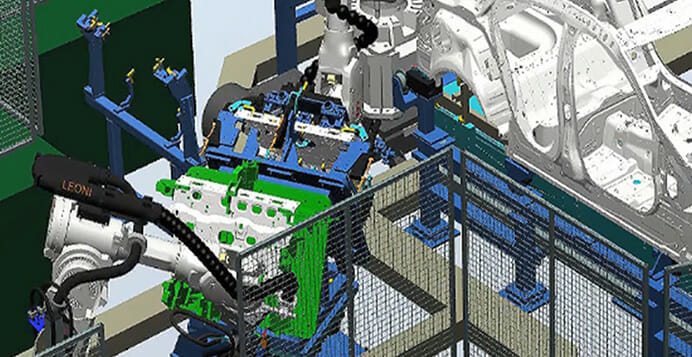

Virtual commissioning is a valuable technology commonly used on large projects, typical of those found within the major automotive manufacturers, where systems containing

hundreds of robots, PLC’s and complex devices are tested, validated and commissioned in a virtual environment. The benefits to these customers, who are generally working on

tight project timescales, are both clear and significant. In these instances it is not unusual for valuable savings on project timescales to be realised as a result of the virtual

commissioning process.

In this article, Tim Bednall – Sales & Marketing Manager for Wood Automated Systems UK explains how the virtual commissioning process developed by the company can

bring equally tangible benefits when applied to smaller automated systems, and why in time it is likely to become the standard approach for all automation projects.

The usual method of commissioning for automation systems has generally followed a traditional route. The system will be designed, individual components parts either

outsourced or manufactured, software, PLC and robot programmes created, and once the system build process is almost complete, initial commissioning will begin. Although

a clear, structured and well-understood process, it is time consuming, and at the point where true commissioning begins, the project timescales are likely to already be

compressed with the target completion date looming.

As many smaller automation projects become more complex, especially in instances where there may be multiple technologies being integrated, the justification

for and the potential benefits to be realised by using the virtual commissioning process become clearer. Therefore within today’s high-pressure and fast-paced environment,

simulation and virtual commissioning is likely to become an essential part of many automation projects. Not only do these processes help mitigate risk, they also significantly

reduce precious set-up time on site. Virtual Commissioning is the process of validating the operation of control system software against a model of the mechanism, machine or

system. In this context, the model could be a 2D or 3D CAD “Digital Twin” of the actual facility. In the context of Realising the benefits of virtual commissioning on automation projects

Industrial Automation, Virtual Commissioning is used to test the operation of PLC, Robotic controls and other complex devices system software by connecting virtual or real

controllers to the inputs and outputs of components and mechanisms that exist within a 2D or 3D virtual machine

A Virtual Commissioning model or Digital Twin of the system is created, and the inputs and outputs of its components and mechanisms connected into the PLC, running the control code.

The software is tested and validated through the Virtual Commissioning model. Test scripts can be designed up-front as part of the Functional Design Specification (FDS), including user interfaces, status and error messaging and fault diagnosis and recovery. Once the software had been tested and validated in the Virtual Commissioning environment, the PLC software and new

mechanical equipment is installed on site.

Wood – Automated Systems UK has made significant investments in simulation and virtual commissioning technology in order to prove automation solutions at the design stage.

The company’s simulation expertise, gained from the use of their systems across many complex automation lines, reduces risk, cost and timescales for customers embarking on automation projects, delivering peace of mind ahead of the actual installation. Engineers are able to use advanced software to explore and analyse a whole host of ‘what if?’ scenarios, allowing the

performance of each element of each solution to be optimised. Once the software for the particular programme has been written, a virtual model is created to demonstrate exactly how the

solution will work.

The virtual commissioning process also makes it possible to create production and maintenance scenarios that would otherwise be impossible or dangerous to implement in real

life. As well as reducing costs, rigorous simulation and virtual commissioning also minimise the risk of damage to machinery and overcomes potential safety related issues keeping the project on schedule.