CAE provider EPLAN has been at the forefront of engineering design technology for many years. Much of the company’s sustained pre-eminence is a result of listening to its customers and potential customers, to gain an understanding of their pain points and requirements. As part of this listening process, the EPLAN Customer Advisor Board has identified a number of specific issues that panel builders are having to deal with in their day-to-day work.

Panel builders are looking for ways to make wiring easier and faster, whilst reducing errors. As long as control cabinets have existed, they have been wired according to a wiring schedule. Although it shows the engineer exactly which connections need to be made, it does not tell them anything about the physical situation. The wiring engineer must therefore first make a translation from theory into practice, and in order to see the end result, experience is needed!

EPLAN Smart Wiring, which is a browser-based solution for wiring optimisation. Smart Wiring visualises the wiring and makes all the necessary data 100% digitally available. Users benefit from a significant drop in error rate and the substantial time savings from the solution not indicating desired connections, but a realistic functional wiring sequence based on the actual cabinet layout.

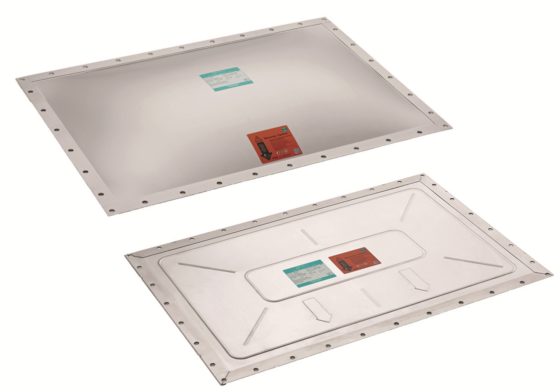

Engineering in EPLAN Pro Panel represents the ideal solution as it enables engineers to design and layout switchboards and control panels. It handles all wiring, component mounting and busbar configuration details, and produces 3D views so that engineers and customers can see exactly what the finished panels will look like, even before work begins on building them. The design can be seamlessly taken over into production without first converting as-designed into as-built.

In addition, using CAE software like EPLAN Pro Panel addresses another important pain point for panel builders as it aids the testing process by ensuring uniformity of design approach and execution. It also ensures that specific requirements relating to the mounting and wiring of components are always met and that errors are detected early in the design phase when they can still be corrected easily and inexpensively.

Another key challenge that the EPLAN Customer Advisory Board has identified for panel builders is the ongoing shortage of skilled personnel. Despite the long-term decline in much of engineering manufacturing, there continues to be strong demand for engineering skills in the UK economy, especially in the fast-growing electrical and electronics industries. Skill shortages are apparent at all levels but especially in skilled areas like panel design, building and wiring.

Fortunately, today’s CAE software helps panel builders to address this burden by helping design engineers to use their time more productively and reducing the skill levels needed for panel assembly and wiring. EPLAN Pro Panel and EPLAN Smart Wiring cannot directly aid recruitment, but they can help every panel builder to get the very best from the employees they already have.