Highlights

Solution

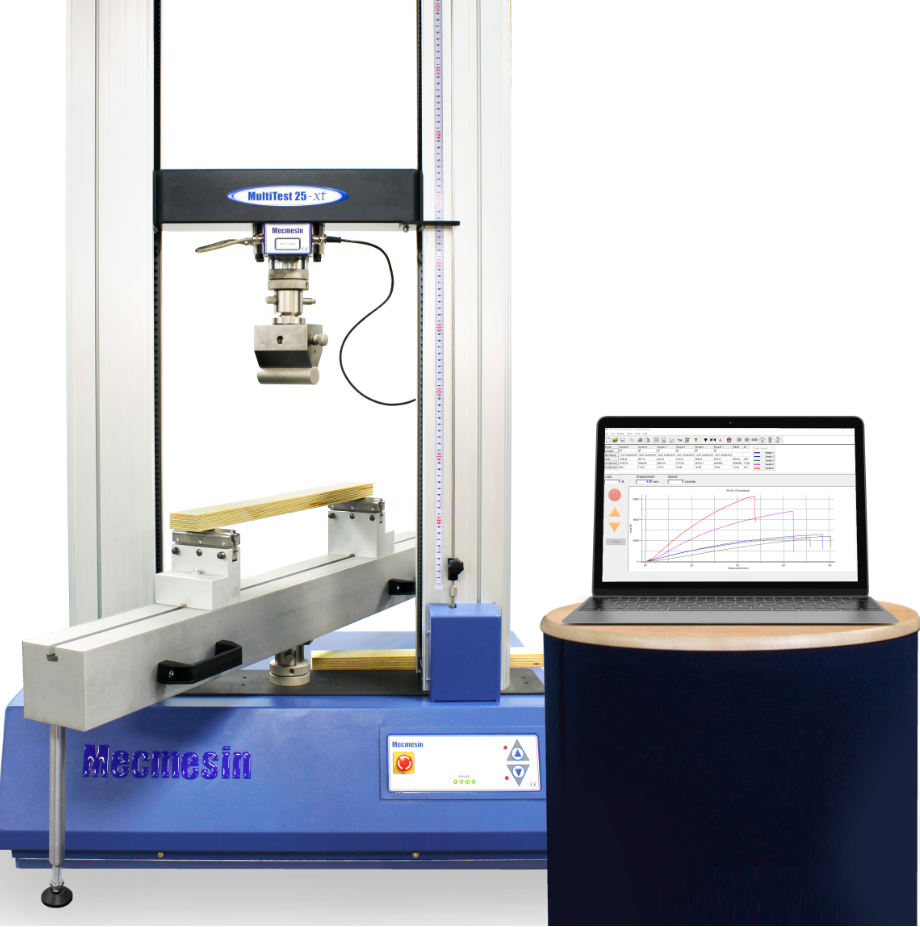

- High-capacity twin-column software-controlled tensile tester

- Heavy-duty bend fixture

- Custom roller-guided peel jig

Benefits

- Software control runs the tests to the standard methods

- Reliable, accurate and repeatable testing to industry and in-house customer standards

- Automatic calculation of the relevant properties of the specimens

- Consistent output of results report in customer-designed format

Requirement

One of Mecmesin’s Lithuanian customers is a leading manufacturer of wooden furniture. Specialising in finished particle board (FPB) impregnation and lamination, it produces primarily for a Swedish end-customer brand, delivering, amongst other items, over 5 million kitchen cabinets a year.

Particle board is a waste-wood product made by heat pressing wood chips, shavings or sawdust and resin together to form structural sheets for a variety of uses in ready-made furniture. Compression is applied multiple times to the particle board sheet to create the tightest possible bond between the resin and the wood fragments. As the boards are significant components in load-bearing kitchen and household furniture construction, it was important for this manufacturer to test their physical strength to ensure they meet the rigorous performance standards required.

Solution

Bend test

The European Norm EN 310 stipulates the method for determining the bending strength of wood-based panels by 3-point bend testing. Mecmesin’s MultiTest 25-xt tensile tester was the ideal choice as a bench-top model capable of applying the necessary compressive load and having the versatility to perform a range of other peel and tensile tests.

A bend jig having a 400 mm span and cylindrical roller supports and anvil was used. The Emperor software of the MultiTest 25-xt automatically calculated the bending strength and modulus of elasticity for inclusion in the customer’s test report.

Peel test

A further test was conducted in accordance with the consumer brand’s standards to measure the peel strength of melamine-faced strips which are bonded to the FPB structure. A dedicated peel jig was produced which allowed the veneer strip to peel at a constant 90-degree angle, whilst the Emperor software detected the areas of high and low bond strength to calculate the overall peel values.

Related test solutions

Furniture suppliers wishing to test to a greater range of standards also consider the following methods:

- EN 311 Tensile test to determine surface soundness of wood-based panels.

- EN 319, ISO 1607 Tensile strength – perpendicular to particleboard and fibreboard.

- ASTM D1037 – Compression parallel to surface, plus fastener-holding tests.