FOR HIGH SYSTEM PRESSURE DUTY APPLICATIONS

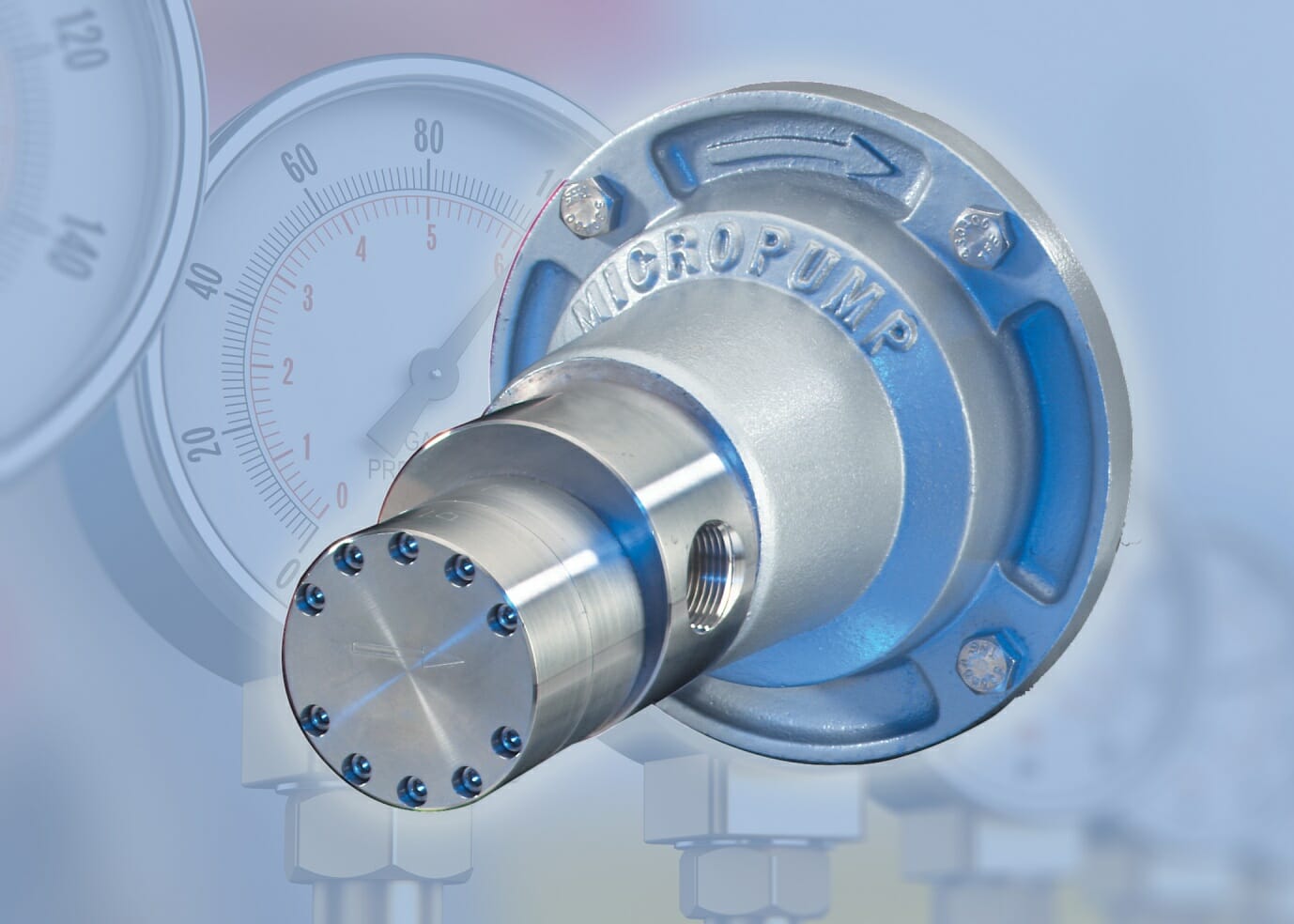

The unrivalled MICROPUMP range of magnet drive gear pumps has recently been extended to include new options which provide exceptional pumping performance for high system pressure applications. The GLH Series compact, magnetically driven external gear pumps are designed for fluids handling applications with system pressures up to 103 Bar (1500 psi) and maximum differential pressures to 8.5 Bar. They can deliver flows from 2 lit/min up to 22.0 lit/min (at 2850 rpm) on liquids with a maximum viscosity range up to 2500 cp, at temperatures up to 121ºC.

GLH Series pumps are designed to deliver a rugged, reliable and leak-free performance for any high-precision pumping application and, thanks to their compact, miniature size, can be easily incorporated into the design of high-precision fluids handling systems. Typical applications include sampling from crude oil pipelines and on sub-sea vessels, refrigerant recovery duties involving transferring pressurised liquids from cooling systems and mechanical seal flushing to cool or clean seal faces.

The external gear design provides the benefit of a smooth, pulse-free and highly accurate output, so the distribution of the pumped fluid is even and constant, compared to the more unpredictable pulsed flows from other types of pump. Also, the cavity style gear design is easy to service, the incorporation of a magnet coupling removes the need for a shaft seal and so provides safe, leak-free pumping whilst the wide range of wetted materials ensure exceptional chemical resistance.

The GLH Series can be coupled with multiple drive and motor options while a choice of configurations means they can meet the most challenging applications. For example; three standard gear sizes, multiple gear, body and ‘O’-ring materials, optional high-torque magnets and NEMA and IEC drive mounts.