Lee Spring is currently working around the globe playing a pivotal role in the manufacture of critical components and supporting quick lead times essential in the COVID-pandemic 19 fight.

Lee Spring employees have sprung into action to prioritize critical products needed for medical devices. Many Lee Spring customers supply equipment needed for all areas in this fight including life-saving devices, testing and diagnostic equipment, research and development, and for the supply of hospital equipment.

Steve Kempf, Lee Spring CEO stated that “our top priority has always been the safety and well-being of our employees, customers and communities. We are focused on this now more than ever. While we have always known that our customers – and in turn, our springs – play an important role in people’s daily lives, the often critical nature of this role has been starkly revealed through the current crisis, so we are very proud to support them in every way possible right now.”

As critical needs have shifted rapidly in the early stages of this pandemic, Lee Spring has been able to also shift manufacturing to meet those critical needs. Lee Spring employees have become front line hero’s in this fight as they have gone above and beyond to ensure that both the workplace is a safe environment and also by working hard to ensure on time delivery for critical components. In the earliest days, it became clear that a number of medical devices, especially ventilators, was going to be a very high priority. This is a complex device that requires many engineered components, including a number of springs. Medical suppliers from around the globe were in need of our parts to fill the supply chain very quickly.

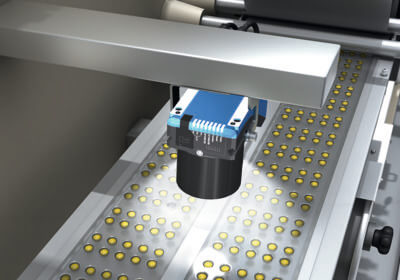

As the weeks unfolded, the demands and needs have been shifting quickly to other components. Testing equipment has become a major priority around the globe and many also require specialized and custom springs. Lee Spring has been supporting medical customers for decades and many of those customers are at the forefront of this pandemic fight. Lee Spring engineers have worked closely with many of these critical medical products for years and in many cases have been involved in the earliest designs and R&D stages. Lee Spring often works on custom designs from inception through research and development, all the way to final long-run production supply.

Lee Spring is uniquely positioned for each design and manufacturing stage by offering more than 25,000 stock springs available from inventory for immediate delivery, to custom designs to meet detailed and often challenging design parameters. Lee Spring can help to design a spring, suggest materials and finishes, plus provide working prototypes quickly.

To learn more, request a catalogue or quote, visit leespring.co.uk, email sales@leespring.co.uk or call +44 (0)118 978 1800.