Eagle Eye Integrity Specialists are one of the first companies in the world to get their hands on the latest in cutting edge UAV inspection technology, the DJI Matrice 300, expanding their already impressive fleet of Unmanned Aerial Vehicle’s.

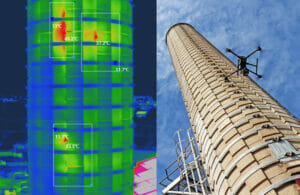

As specialists within the engineering, petrochemical, and marine sectors delivering Non-Destructive Testing (NDT), Eagle Eye Integrity Specialists utilise industry leading UAV technology to conduct high level unintrusive inspections on essential operating assets and structures such as flare stacks, pressure vessels, storage tanks and much more. Operated by CAA approved pilots and experienced NDT Technicians, their drone fleet delivers close inspection capabilities to identify potential defects, structural cracks, corrosion and leakage, moving freely around the structure for a detailed 360 view recording high resolution thermal and digital images.

“Our clients receive an invaluable end to end service, inclusive of UAV and NDT with detailed reporting. We deliver high level essential inspection services that cannot be conducted by any other means; a vital catalyst to increased production and onsite safety. We are now an integral part of many organisations inspection schedules, conducting repeat inspections throughout the year.” Explains Scott Standing, Managing Director of Eagle Eye Integrity Specialists.

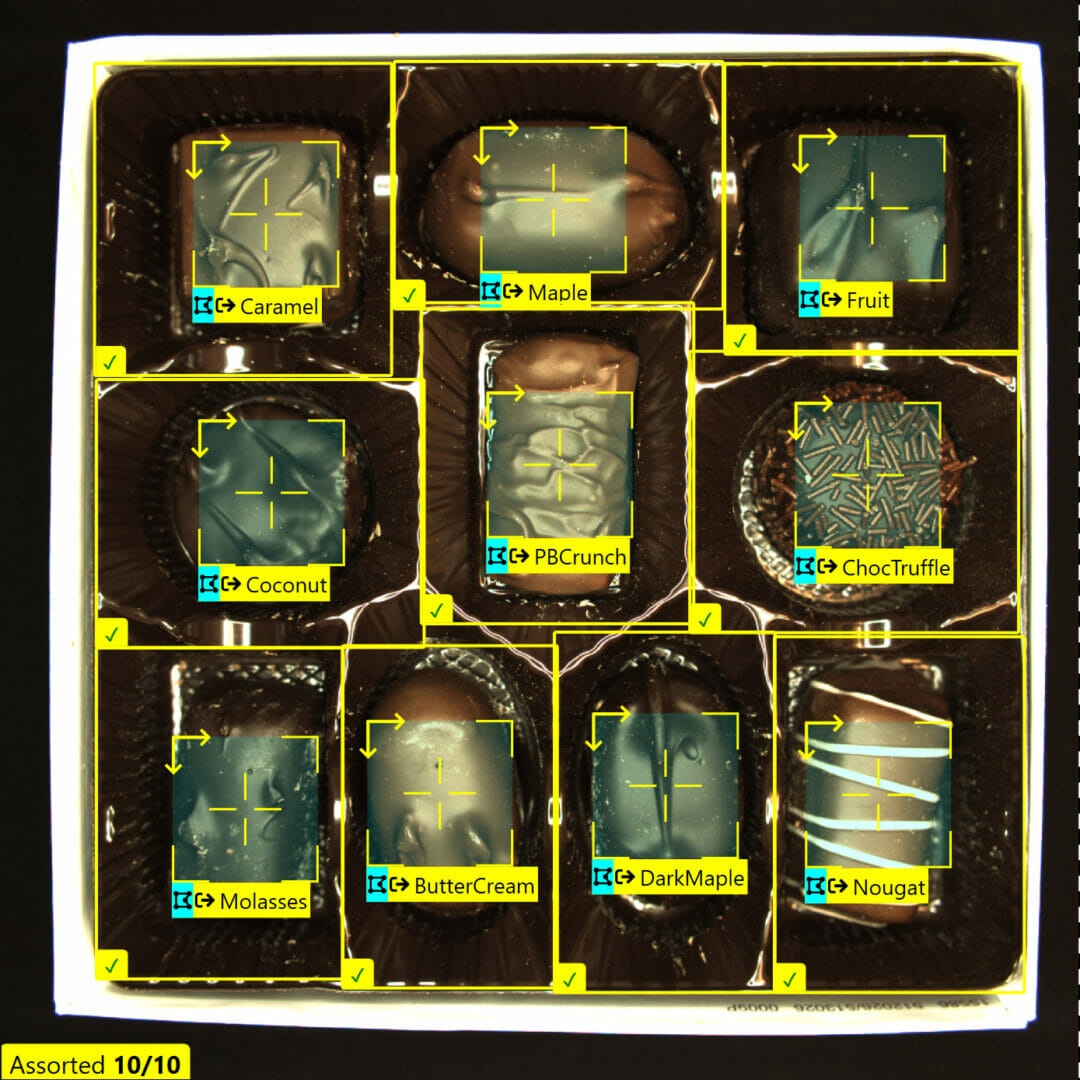

With the addition of thermal imaging technology, inspections and surveys can be carried out whilst operating assets are live, clearly highlighting defect areas which can’t be identified unless offline, which ultimately affects production. As a result, Eagle Eye Integrity Specialists greatly reduce costs and minimise risk, potentially eradicating the need for costly production shutdowns, avoiding the need for scaffolding, working at height and over the side work. In addition, the drone features advanced Artificial Intelligence to provide AI Spot Check’s to automate routine repeat inspections and capture consistent results every time. Onboard AI recognises the subject of interest and identifies it in subsequent automated missions to ensure consistent framing to accurately gauge and record defects over time either using visual digital, thermal or ultrasonic.

Eagle Eye Integrity Specialists mobile control centre also offers clients on-site access to their full inspection, watching, tracking or controlling the digital footage themselves whilst the experienced pilot conducts the controlled flight, providing the next level of inspection service.

The UK based integrity specialists are quality assured by Lloyds register under UKAS (ISO 9001 & ISO 45001), delivering UAV, NDT and ManPower solutions with an international network of experienced specialists throughout Europe and a strong foothold in the Netherlands and Belgium.