The Coronavirus pandemic has highlighted the benefits of working remotely utilising new and existing technologies to monitor and manage operations from a distance, whether a few meters away on the factory floor, or on the other side of the world.

While many forward-thinking businesses had already embraced the concepts behind remote working, the Internet of Things (IoT) and Industry 4.0, there is no doubt that Covid-19 has increased the speed of uptake in many sectors and shown the real benefits of this way of working to the most sceptical of observers.

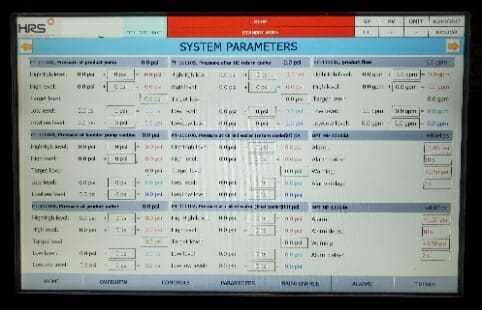

One feature which is increasingly being specified on HRS systems (such as pasteurisers, sterilisers, fillers and food processing systems) is the fitment of remote monitoring and telemetry systems. These are normally based on an ethernet connection, but where the necessary infrastructure is not available, an integrated data SIM can be used instead.

This allows clients to easily manage, operate and analyse equipment performance within their own business, something which is particularly useful for larger companies operating over multiple sites or even across different countries. Another benefit is that HRS engineering staff can easily access the system remotely for troubleshooting or to allow the installation of software upgrades for example.

Matt Hale, International Sales & Marketing Director at HRS Heat Exchangers, comments: “This remote functionality has been available for some time, but it is noticeable since the start of the Coronavirus pandemic how much more popular remote monitoring and operation has become. Our clients can be assured that we are able to meet their requirements in terms of remotely connecting to our heat exchangers and other systems.”