Fraser Technologies works with a pioneering, midlands-based aerospace engineering company to provide extremely high levels of cleaning performance for their mechanical components.

The company is world-renowned in high-speed jet engines, so the requirement for precision and superior levels of cleanliness is easy to understand. Each part needs to be spotlessly clean – with maximum particle sizes of just five microns – in order to perform its role. The team uses a coordinate measuring machine (CMM) to ensure each component is machined to very accurate tolerances. The tolerances for measurement are just five microns, so even small particulate material has an impact on this process.

With demand for ever higher levels of cleanliness and increased efficiencies across the business, the company identified that improvements could be made in some of their component cleaning processes. They had been using an aqueous system, however the failure rate on the MMI system was around 70% due to contamination, and Fraser Technologies was keen to trial a solvent solution, which they believed would deliver the best results.

Fraser Technologies recommended Opteon™ SF79®, which can remove particulate down to submicron levels without leaving residues, and has strong environmental credentials with a Global Warming Potential (GWP) of less than 15. Opteon™ SF79® was already used elsewhere in the business and had been approved on site, so they had confidence in its credentials and capabilities. Opteon™ SF79® has recently been superseded by SF80®, which has a GWP of less than 2.5.

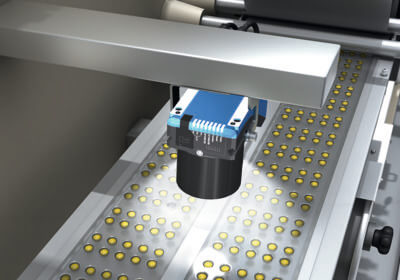

Along with the solvent, Fraser Technologies proposed an innovative, bespoke machine, which offered increased automation and much better linkage. This provided immediate time and cost savings and future-proofs the machine, with an option for faster washes and increased loads when required.

Since instalment in June 2019, the company has seen no failures on the CMM system due to poor

cleaning, and a 100% success rate for cleanliness for these components. It has also reduced rework and lead times, and allowed for increased volumes, saving significant time and money.

The company’s manufacturing engineer in charge of the process, said: “The 100% cleanliness success rate is exactly what we were looking for. The process is significantly more efficient, reducing lead times and costs.”

To read the full case study, please click here