Jo Stephenson, MD PHD Marketing, Director of FIAUK (Flexographic Industry Association UK), and Partner to Easyfairs

The packaging industry is no stranger to revolution.

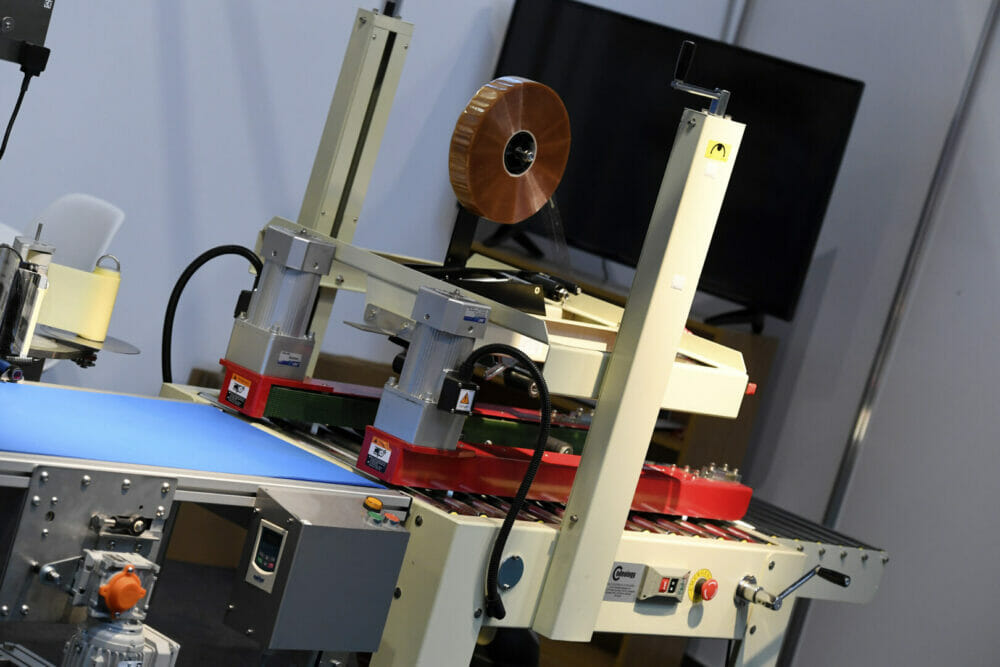

Some arrived with a bang, and others with a whisper, but many have come and gone since the advent of the commercialised cardboard box in the 19th century. Today’s advanced production lines have made previous generations of technology obsolete several times over, with automation workflows, precision-engineered machines, and smart logistics all augmenting the production of each modern packaging solution. It is unsurprising, then, that it is uniquely prepared for another revolution set to burst into life.

The fourth industrial revolution, or industry 4.0 or 4IR as it’s become known, proposes rapid acceleration of business through technology interconnectivity and next generation automation. Serving up digitalisation, cloud-based technology, augmented and virtual reality solutions, as well as artificial intelligence and 5G (if you are blessed enough to work in the right location!), Industry 4.0 sees the potential for organisations to thrive through streamlined and connected processes that minimise human intervention. This is due to the creation of greater resilience and productivity, with sustainability embedded into core operations, and new hyper-personalised experiences and intelligent products, processes and services becoming the backbone of business.

Digitising every step of a business process enables companies to reimagine how their products and services are designed and engineered, sourced and supplied, manufactured and serviced (if required) once shipped. But are we really thinking that far ahead in the packaging and label industry? Do we have that vision of the future and are we working on the trappings of industry 4.0 in our businesses today to ensure we stay ahead of the curve – especially, in the context of the challenges presented to the industry in the last two years?

But for a few exceptions, the answer has to be no. Being honest with ourselves, automation has always been the driving force of the industry – volume and speed often being the name of the game driving competitiveness. However, this has been about individual machines or process capabilities, not the joined up, hyper-connected, data-driven world that Industry 4.0 proposes.

There is no doubt that printing, converting and packing machines are getting faster, more consistent, versatile and user friendly – indeed printing or packing at a touch of a button is nearly a reality. However, the connected workflow across machines, business functions and to the external world, across customers and suppliers, is still left wanting. And yet, the industry is crying out for design and production agility to meet today’s brand and retailer needs.

Over the past two volatile years, suppliers across the industry have been hit with well-publicised disruptions – from paper, plastic, and components outages, across to manpower shortages for logistics and shipping, through to the torrid time we all endured through the pandemic. Surely this volatile world should have taught us that digitising, automating and connecting had to provide more stability and reliability to our supply chains? It should be a catalyst for change and investment in driving robustness and stability into operations, while optimising for versatility and agility. So, what is holding the industry back?

Interestingly, there can be a myriad of reasons that packaging, label and fulfilment companies resist the move to digital transformation. Clearly, the obvious sticking point can be the sheer investment levels required to make the switch. This is not just investment in hardware and software, but the time and skills required to have the planning and implementation process nailed down can be considerable. Core to this is really being able to accurately map out the business processes and have the vision for what can be achieved – the benefits that can be accrued from moving from an analogue set-up to a completely digital one.

With today’s ageing population in the packaging industry in particular, the IT literate, skilled leadership required to deliver the programme can often be missing too, and the resulting culture change needed to embrace new technology and new working patterns can be daunting. The industry already has skilled labour shortages – adding new IT requirements to the mix can feel like a step too far in what is already a challenging market environment.

One roadblock (often in play but suppressed in discussions) is the natural fear of the unknown. Driving a comprehensive digital transformation across a business, especially a multi-site organisation, can be scary. Combine this with worries over the impact on labour and having a lack of skills to handle the ‘new world’ can mean businesses resist change. The reality is that digitisation doesn’t necessarily mean making workforces redundant today (although the jury is still out on long term effects of technological unemployment1). Recent studies have indicated that labour is routed to more value-adding tasks or shifted to growth opportunities, as a result of the transformation process. What is eliminated is waste in all its forms – physical, time-related, over-processing, motion, and defects – and what is achieved is a more streamlined, efficient and satisfying work environment.

The final threat to change often cited is the risk of digital disruption – hacking, data and IT security and stability. Does moving to an entirely data-reliant digital model actually present risks to the business, rather than reduce them? The only answer to this can be investing in the right infrastructure with the right partners to bring data confidence into the plan.

The reality is that the packaging industry is ready for change. Whether it‘s economic and global supply challenges, the ageing workforce, inability to attract young talent or a general recognition that ‘the times are a’changing’, the scene is set for digital disruption. The industry already has some great OEMs and software suppliers leading the way – connecting machines, workflows and creating the seamless communications needed across sites, geographies, departments, functions and assets. What we need now is some brave leaders with a clear understanding of what can be achieved and how, and Industry 4.0 can quickly become a reality delivering the competitiveness, resilience and versatility that today’s industry so badly needs.

Leaders from across the cutting edge of packaging will gather together on February 15 & 16 at Birmingham NEC to discuss this new frontier for the industry at Packaging Innovations & Empack, Featuring Contract Pack & Fulfilment. Attendee tickets are available to book now, for free, at www.packagingbirmingham.com.

References

1 Impact of Industry 4.0 and Digitization on Labor Market … – MDPI

https://mdpi-res.com › sustainability-13-07703-v4

About the author

Joanna Stephenson is a former Product Director at Dow Chemical and Marketing leader at Sun Chemical and LINPAC Group. Jo works across the print and packaging supply chain both in the UK and internationally working with over 40 companies, which gives her a unique insight to the key trends and challenges today’s industry faces. For more information on Jo’s work, please visit www.phdmarketing.co.uk