Once again, ODU exhibited at DSEI, so as to show-off their latest developments in military connector technology. But if you missed the exhibition, here’s a summary:

The ODU-AMC® T-Series Connector – Beyond 38999.

The ‘T’ stands for Three-on-One as three locking variants of plug [push-pull, break-away or screw-lock] can fit the same receptacle, in shell-sizes that give space-envelope savings over comparable density MIL-DTL-38999M connectors, but with the same, or improved, technical performance.

The ‘T’ stands for Three-on-One as three locking variants of plug [push-pull, break-away or screw-lock] can fit the same receptacle, in shell-sizes that give space-envelope savings over comparable density MIL-DTL-38999M connectors, but with the same, or improved, technical performance.

Cables can use a standard MIL-M85049 back-shell or ODU over-mould and the crimp contacts can be standard MIL-AS39029, or an ODU design.

Now, in-vehicle OEM’s can utilise the same bulkhead fitting across all equipment,

leaving the locking mechanism to be determined by the plug-in equipment.

Even Higher Data Rates

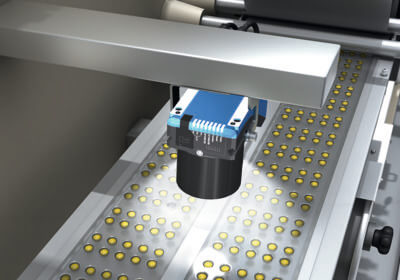

Having already produced the ODU-AMC® High Speed Data series that can combine and transmit all common protocols, with transfer rates up to 14.4 Gbits/s, DSEI will showcase a further development, the ODU AMC® Series T Expanded Beam Connector. It combines the advantages of a classic expanded beam – insensitivity to dirt, scratches etc. with the high-performance attenuation of a physical contact (< 0.3 dB). Result – 3 to 4 times the number of glass fibres in an identical installation space, so increasing the transmission capacity significantly, while adhering to the attenuation budget.

Soldier Communications.

A new power-efficient connector for soldier communications.

ODU AMC® NP

Easy handling and robust, with apps such as:

- Tactical soldier batteries

- PDU (Power Distribution Units)

- CWB (Conformable Wearable Batteries)

- C4ISR peripherals

It is compatible with open-architecture standards such as NATO STANAG 4695, Nett Warrior and GOSSRA

Supplier Partner

ODU also offers a complete service – including connectors, cable, over-moulding, watertight-potting and metalwork – supplying your sub-system from one totally reliable source – shipped to line.

Consultation, requirement analysis, product design & development, prototype manufacture, pre-production batch delivery, technical documentation – taking care of everything necessary to produce a great system solution specifically for you.

However, the company’s skill-set, as an independent connector manufacturer, includes one further special ingredient – flexibility – the ability to sit down with the customer and design a way out of a problem, the ability to produce a connector that is truly fit-for-purpose and to deliver that both on-time and within budget.

So, if you’re faced with a connector or packaging conundrum, then why not get in touch and tell them about your problems – they may have an answer.