The VCM-3 condition monitoring system (CMS) will be in live action on the NSK booth at EMO

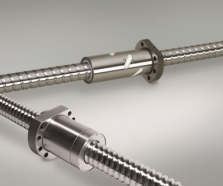

NSK is the only manufacturer to offer a complete development and supply service for

the essential parts that machine tools require, including high-precision, high-speed

ball screws. However, the company also helps customers to apply novel

technologies that support extended product life and the potential deployment of

predictive maintenance strategies. Therefore, central to the display on Booth C42 in

Hall 7 at EMO Hannover 2023 (18-23 September) will be a live demonstration of a

condition monitoring system developed by Brüel & Kjær Vibro (B&K Vibro), a

member of the NSK Group. Involving a pair of NSK ball screws, this fascinating

exhibit provides a compelling reason to visit the booth.

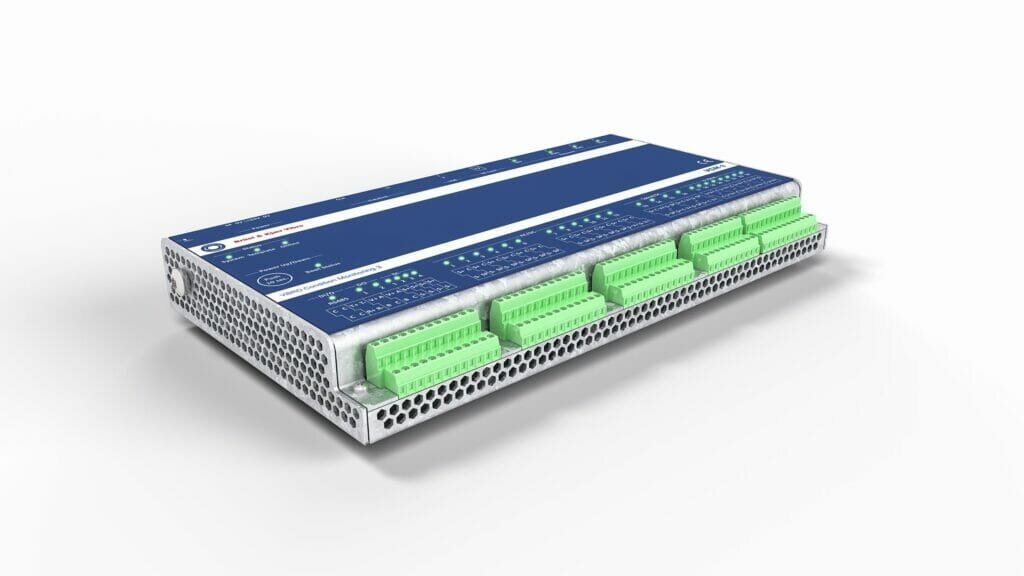

The live demonstration will centre on the VCM-3 condition monitoring system (CMS),

produced by Brüel & Kjær Vibro, a member of the NSK group and one of the leading

worldwide suppliers of condition monitoring solutions for rotating machinery. Specifically,

the VCM-3 plus vibration sensors will showcase proven credentials for monitoring linear

motion equipment such as NSK ball screws. The system, based on compact, cost-effective,

cutting-edge technology helps turn vibration data into real business value.

On a wider level, the VCM-3 provides automatic machine fault detection and diagnostics,

NSK S-HTF series is the world’s first ball screw application involving Tough Steel

technology

adding a new dimension of healthcare awareness to machine shop assets. Users do not

require any previous diagnostic expertise: the system uses specially defined measurements

that not only facilitate the early automatic detection of developing faults, but also give a

diagnostic indication of the fault type and its severity. The VCM-3 is simple and fast to

configure. A built-in OPC UA server enables seamless integration of VCM-3 data to DCS,

SCADA, data historian and other systems. The system is also expandable using other

components of the broad B&K Vibro solution portfolio to provide plant-wide condition

monitoring.

Ball screws will of course be a core technology on the NSK booth. Making its debut

appearance in Europe will be the company’s next-generation ball-screws for high-accuracy

machine tools. Offering reduced motion errors and no ‘second glitch’ phenomenon, these

new ball screws help enhance the surface finish of workpieces, in turn reducing or

eliminating the need for secondary polishing/burnishing operations.

Another ball screw on the booth will be the NSK low-temperature series. Features include

45% less friction loss (heat generation) in comparison with conventional systems at the

same rigidity. Also making its European exhibition debut at EMO will be the company’s HFT

series for high-load drive applications, which offers up to two times longer life than

conventional ball screws.

Further NSK ball screws on the booth will include the S-HTF range, which takes advantage

of NSK’s proprietary Tough Steel to help combat high loads and contamination.

NSK DIN-standard ball screws ensure dimensional and tolerance class suitability for

European machine tool applications

NSK will also shine its EMO spotlight on linear guides, including the new DH/DS long-life

series. With a world-leading dynamic load rating, the DH/DS delivers over twice the running

distance of the company’s conventional NH/NS series. NSK will also present its proven RA

series roller guides featuring highly dust-resistant seals.

The company is world-renowned for its bearings and EMO will provide the European launch

pad for NSK’s ROBUSTDYNA ultra-high speed, high-load capacity angular contact ball

bearings. Ideal for machine tool spindles, these ground-breaking new bearings feature

bigger bearing balls to increase maximum load capacity by up to 15% in comparison with

the previous-generation solution.

A further major introduction at the show will be NSK’s ROBUSTGRD grease for high-speed

spindle bearings, which improves seizure resistance and reliability in coolant environments.

The booth will also showcase NSK’s SURSAVE (TSR) bearing cage for angular contact ball

bearings that deliver energy savings, high speeds and reduced vibration during use on

machine tool spindles. A range of various NSK super precision bearings and high-speed

motor bearings will round-up the showcase for machine tools, alongside thin angular

contact ball bearings for robots.

About Brüel & Kjær Vibro

Brüel & Kjær Vibro is one of the leading worldwide suppliers of condition monitoring

solutions for rotating machinery. The comprehensive product range comprises vibration

sensors (acceleration, velocity and displacement), vibration monitors, handhelds and rackbased plant-wide integrated monitoring solutions. These products plus a suite of

comprehensive services fulfil the most demanding applications for safety, condition and

performance monitoring of rotating machinery.

Based on more than 80 years of experience and a world-wide sales and support network,

Brüel & Kjær Vibro’s monitoring solutions have successfully reduced downtime and

maintenance costs and increased machine reliability for our customers world-wide.

For more information, visit www.bkvibro.com