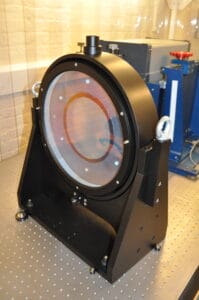

The OS series of large-diameter mirror mounts from Optical Surfaces Ltd. are proven to provide a secure platform for larger, high-precision flat, off-axis, and spherical mirrors in stability-critical applications. Manufactured in robust, black anodized aluminium, OS series mounts have traditionally been available in four standard sizes to accommodate mirrors up to 300mm, 400mm, 500mm and 550mm diameter.

The new OS350 and OS450 mounts provide researchers with a smaller and lighter stable mounting platform for mirrors between 300 – 400mm and 400 – 500mm diameter. No longer do you have to purchase the larger and heavier next size up!

- Two different mirror mounts from the OS Series (courtesy: Optical Surfaces Ltd.)

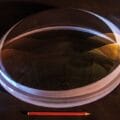

- A new OS350 mount holding a mirror coated to be reflective in the Near Infrared spectral waveband (courtesy: Optical Surfaces Ltd).

All six OS series mounts make it possible to rapidly align a large diameter mirror within a few arc seconds. Each mount comes with a baseplate to facilitate rapid and simple mounting onto an optical table. Angular alignment of mounted mirrors is quickly and precisely achieved about the vertical and horizontal axes using dual-action adjusters with fine-screw and ultrafine differential micrometre action.

OS series mounts are supplied with adjustable feet to facilitate rapid and simple mounting onto an optical table. As an option – OS series mounts may be motorised to facilitate remote operation in hostile environments or for use in limited space applications where manual adjustment may be difficult.

For further information on the expanded range of OS series mounts please visit https://www.optisurf.com/index.php/products/product-6/mounts-and-mounted-optics-gimbal-d300/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com.

Optical Surfaces Ltd has been producing large diameter optical components, optical systems, and mounts for more than 60 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk. This provides an environment where temperature is naturally thermally stable, and vibration is extremely low. With such stable conditions testing of high precision optical components and mounted mirrors becomes quantifiable and dependable. In addition to these natural advantages, Optical Surfaces has invested in an extensive range of test equipment and have developed methods to ensure accurate and reliable testing.