Process factors to consider when specifying an adhesive

When specifying an adhesive, the primary consideration is functionality — will it act as an adhesive for the lifetime of the assembly? But it’s also important to consider how the material will work in production — its processability. Considering processability at the design stage can save time, money, and effort. Here Kevin Brownsill, Head of Technical: Learning and Development at adhesives specialist Intertronics, explains some important process considerations for design engineers when specifying an adhesive.

An adhesive’s processability covers everything from how it is removed from its packaging, to mixing, dispensing, and curing it. Understanding the processability of a material for your application involves weighing up production requirements, such as speed and scale, against the adhesive’s properties. If a material hits all of the technical criteria, but can’t be repeatably and accurately applied into a final part at a speed the production team are happy with, it’s probably not a good fit. Similarly, if the process can be perfected by hand during the R&D stage, but not easily replicated by automation, it is unlikely to work in large scale production.

Shortlisting materials

Typically, a design engineer will start the specification process by assessing the technical characteristics of a material as explained on its data sheet. While a great way to shortlist a handful of candidate materials, it’s important to remember that data sheets are not exhaustive — knowledge, experience, and tests are needed to establish if the data can be extrapolated for your unique application. A good adhesives supplier will understand the full complexity of the project, and make recommendations for materials and dispensing technology for you to evaluate based on all of the relevant factors.

In many cases, there will be multiple materials that offer the required functionality. We recommend trialling more than one material — you may find that two adhesives give similar technical performance, but one offers significant process or implementation ROI benefits.

Out of the box

Adhesives are supplied in everything from small syringes or vials containing a few millilitres to large 220 litre drums and beyond; but not every material is supplied in every size and packaging type. If the material you select is only available in 10 kg batches, but you require a 1 nl shot, you may wish to consider an alternative to reduce waste or having to invest in appropriate handling equipment.

Once you have established whether the material is available in suitable packaging, you can think about how to apply it. This involves trialling possible dispensing methodologies, which can be anything from simple time pressure dispensing, up to fully automated volumetric dispensing, depending on the repeatability and accuracy requirements.

A material’s viscosity often impacts its suitability for an application, both technically and in terms of the process. Adhesives are available in everything from water-like viscosity (e.g. a cyanoacrylate adhesive), to very thick pastes (e.g. a thermally conductive silicone). Each extreme can be difficult to process for different reasons. While a low viscosity material may cause problems with dripping, a high viscosity material may be a challenge to remove from the packaging or apply to the part. For example, if you need a material to flow into certain areas and its high viscosity means this can only be achieved with coaxing by hand, the process is unlikely to be scalable into high volume production. Your adhesive supplier can talk you through which materials will be easy to dispense for your application based on their physical properties.

Production process steps

There are numerous processing steps that may be required as part of an adhesive project, such as thawing, decanting, warming, and mixing. Typically, the fewer steps involved in the process the better, as it reduces labour, risk, and investment requirements. If a material requires a great deal of processing steps, the design engineer could look for an alternative that has similar technical properties but fewer processing requirements.

Single part adhesives are easier to dispense and handle than two-part ones, which must be mixed. UV curing adhesives, for example, enable a fast cure, no-mix process, that improves efficiency and overall economy. You may wish to trial these to see if they offer the required functionality.

Time-based considerations

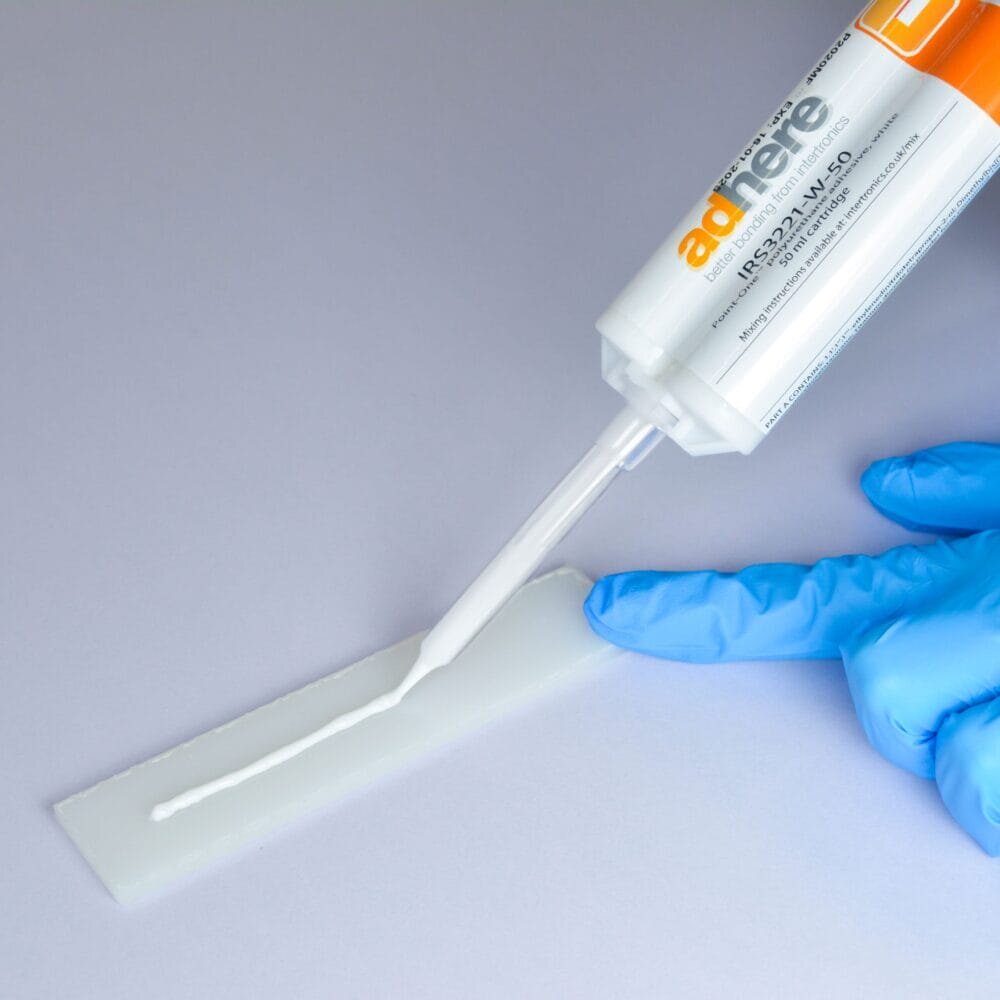

Two-part materials, such as epoxies, polyurethanes, silicones, and methacrylates, begin to gel and start to change in viscosity immediately upon mixing. An understanding of how a material changes over time can dictate how it is used. With two-part materials, for example, a metering and mixing system can be employed at the point of dispense.

You may need to consider the working life — the amount of time a mixed material remains low enough in viscosity so that it can still be readily applied with the appropriate accuracy and tolerance required in your application — and whether the working life suits your process. In some cases, you may need to modify dispensing technology to accommodate. For example, if you are dispensing with a two-part epoxy that cures in 5 to 10 minutes, you may wish to use a dispensing system with an automatic purge, to keep fresh material in the nozzle.

Another important time-based consideration is cure. There is a huge variation in the amount of time different adhesives cure, from seconds to hours, or even days in the case of slow-curing epoxies and silicones. A long cure regime means parts may need to be set aside to cure offline, taking up space and resources like jigs and tooling. Adhesive that have purely thermal cures will require some sort of oven, which carries both an upfront cost and an ongoing energy expense.

Ideally, the cure time will fit into production speeds and takt times, to avoid creating bottlenecks or large amounts of work in progress. There are rapid curing adhesives available, such as cyanoacrylate adhesives and UV curable materials, which can be attractive from a process perspective, but not always suitable from a performance or process perspective.

Health and safety

If your team will be handling the material, it is important to consider whether the adhesive will introduce additional health and safety requirements. Some processes may carry an increased risk of RSI, such as if a team member has to use excessive force to remove the material from its package. In this example, one potential solution is to switch to a pneumatic system. Alternatively, consider switching to an alternative material that is easier to handle.

Always review the latest Safety Data Sheet as part of the adhesive selection process. You will need to establish whether ventilation is needed, what PPE is required, and if there are any pertinent regulations. For example, from August 23 2023, users of polyurethane adhesives with a monomeric diisocyanate concentration of >0.1% require training. If the health and safety issues are a concern, you could trial alternative materials, for example Point One™ structural polyurethane adhesives use micro emission technology and therefore require no training.

Typically, the fewer processes that need to be done by hand, the better — a machine that metres and mixes through a nozzle offers better repeatability and health and safety than an operator doing it by hand.

Scaling up

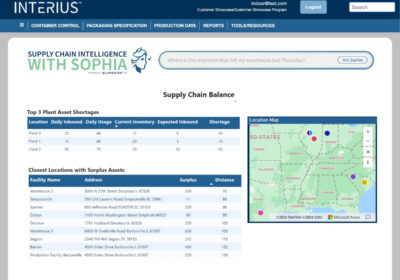

An understanding of expected production quantities can impact adhesive choice with regard to cure time, dispensing method, and even packaging. What works to make one component might look different from 100, and different again from 100,000.

If it is likely production will scale up, the design engineer may wish to specify a material that is readily automatable, so that higher throughput and volume can be achieved. Certain materials can be packaged for both hand application and in bulk, which can make the transition easier. For example, the two-part clear potting polyurethane Opti-tec 4200 is available in easy-to-use 50 ml cartridges and also in bulk kits of at least 1 kg. If you are looking to scale up a process later, your adhesives supplier can help you take an incremental approach, so that your current investment works as part of your future one.

Considering the processability of an adhesive at the design stage greatly reduces the chance of hurdles later down the line. To keep the process simple, you may want to consider automation, single part materials with no requirement for mixing, fast in-line cure and process friendly packaging. The earlier you contact an adhesives expert in your new product introduction journey, the better they can help you.

For more information on building an adhesives process, visit our website. Or, to speak to a specialist, call 01865 842842.