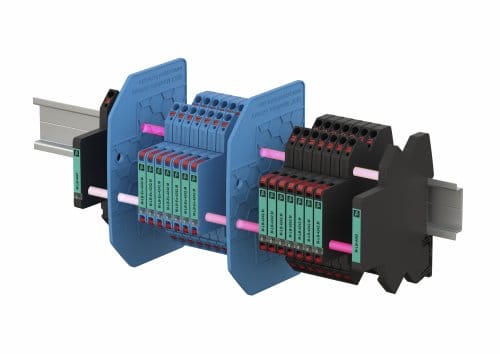

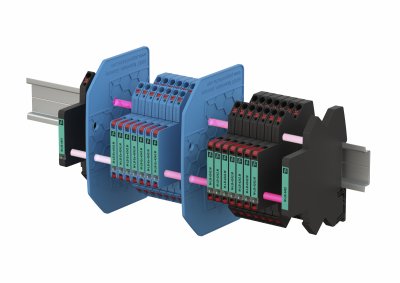

Modularity, loop disconnect function, and fault monitoring for signal lines up to SIL 3 in accordance with IEC/EN 61508 – these features are combined in the new M-LB-4000 surge protection system from Pepperl+Fuchs. The devices limit induced transients from various causes on signal lines, for example, due to lightning or switching operations. The 2-channel modules support higher plant availability: Since the protective function is completely housed in the plug-in protection module, there is no need to for rewiring during the replacement.The M-LB-4000 consists of a two-part surge protection and a two-part fault status monitoring system.

The protection module contains all protection components. It can be replaced without tools while the base module remains in operation. The device has a status indicator on the front panel. When pulling the protection module, the relevant signal circuit remains interconnected via the base module mounted on the DIN mounting rail. The disconnection process does not lead to any signal interruption, meaning that a protection module can be replaced without impairing plant operation.

The M-LB-4000 allows easy commissioning and servicing using a loop-disconnect function and uninterrupted protection module replacement during ongoing operation.

If the protection module is rotated by 180 degrees and plugged in, the signal circuit will be broken via the integrated isolating function. This simplifies servicing work and loop checks and allows insulation tests to be performed during commissioning or repeated testing.

The two components of the fault status module monitor the status of multiple surge protection barriers. The kit consists of two parts; the optical emitter / receiver and the optical deflection unit. If a fault occurs in one of the barriers to be monitored, the optical signal is interrupted and the fault is identified. The fault status module provides an LED status indicator, enabling visual inspection of the surge protection to meet the normative requirements for regular testing. In addition, a status message output is available, so that the block in which the fault occurred can be identified. One fault status module can monitor up to 50 modules.

At 6 mm, the small width of the modules saves space in the switch cabinet. During retrofitting, existing common disconnect terminal blocks can be replaced regardless of space requirements.

Caption: Two components of the fault status module (each external) monitor the status of the protection modules. Here, there are two blocks for intrinsically safe circuits and signals from/to the safe area

Download URL

https://myconvento.com/public/get_file.php?id=enc2_Y2t4R2FYVmxVWFZOUlRacmNsaDFaMUpHV2tkM1FUMDk&download=1

Caption: M-LB-4000: Two-part fault status module (external) and base with protection module in the middle, for intrinsically safe circuits and signals from/to the safe area

Download URL

https://myconvento.com/public/get_file.php?id=enc2_VVZocWJtcG1XRXRNUjI5dWIzSmhaV1pTWVZGRVVUMDk&download=1

About Pepperl+Fuchs

With 6600 employees worldwide, Pepperl+Fuchs recorded sales of EUR 790 million in 2021. The Pepperl+Fuchs Group is one of the leading companies for industrial sensor technology and explosion protection. The headquarters in Mannheim, Germany, represent the core of the company’s technical expertise, where engineers and specialists research and develop the latest technologies and products. Originally a small family business founded in 1945, Pepperl+Fuchs is now represented on all continents by more than 40 subsidiaries on 6 continents. Our global presence gives us the best of both worlds: the highest technical standards plus efficient, cost-effective production facilities. Pepperl+Fuchs has developed into a partner for worldwide users of automation technology, and offers the most comprehensive portfolio of tried-and-tested components for the demands of manufacturing automation and process automation.