Flaps, covers, sliding doors: fully automatic movement with Industrial POWERISE®

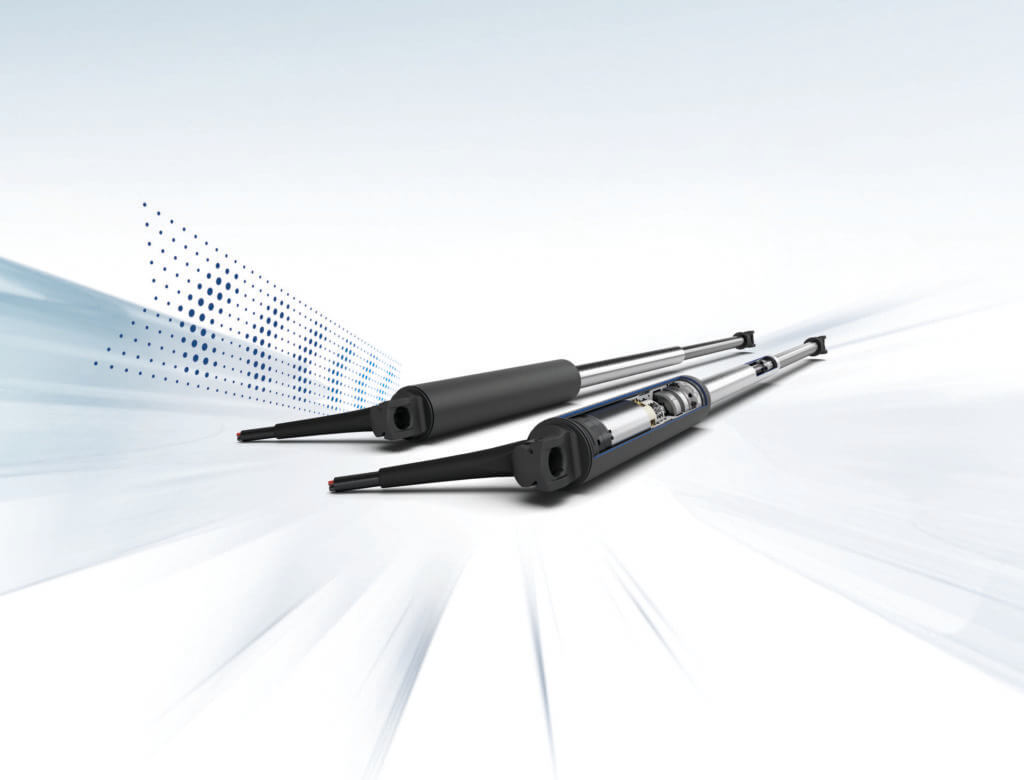

Stabilus presents Industrial POWERISE®, the new product family of electromechanical drive systems for industry. Mechanical engineering and automation manufacturers benefit from safe, comfortable, and fully automatic movement of maintenance flaps, covers, adjustment units and sliding doors. The globally successful Automotive POWERISE® drive is installed today as a lift gate drive in almost all passenger car brands.

Electric lifting and lowering – fully automatic movements

Industrial POWERISE® enables, improves, and automates the opening, closing, lifting, lowering, adjusting and holding of movable components. The base variant IPR35 is now available starting in October 2023. It offers internal sensors and is the ideal solution for moderate forces of up to 2.5 kN. Additional variants will follow in 2024 with expanded functions and for high force requirements: from IPR35 Smart and IPR40 to the smart “flagship” IPR40 Smart. In the American markets, the corresponding product launch is expected to take place six months later.

Maintenance-free and suitable for combination with gas springs

Industrial POWERISE® stands out for its maintenance-free operation suitable for industrial environments, with protection up to class IP69k. Manual adjustment protects the user and machine even in emergencies like power outages. Because the electromechanical drives can be connected to Stabilus pneumatic springs, dynamic forces can be combined with load compensation – a unique system offer within the industry.

Standard variants with individual options

Various combinations of technical functions and parameters are available even in the standard variants. “Our customers can choose from available spindle pitches from two to 30 millimeters, multiple connection options and different forces, strokes and speeds” says Jürgen Roland, VP of the Business Unit Industrial at Stabilus Group.

The IPR35 and IPR40 product variants are recommended as the standard for manufacturers who install their own controllers in their products.

Customized adaptation or a custom series

Through the expert brand ACE, mechanical engineers can even purchase small quantities from the factory in different lengths and configurations. Hahn pneumatic springs support customers in individual adjustments, expected to be available from spring 2024 – such as custom lengths, motors with a range of available voltages and torques, and different spindle pitches. In addition, Industrial POWERISE® allows for joint development of drive series, which Stabilus then manufactures exclusively for the individual customer.

Through customization, the Stabilus Group is reinforcing its position as a Motion Solution Provider. Industrial customers can receive coordinated overall solutions for their movement control needs. The product family builds on the success of the IATF certified Automotive POWERISE® drive. In around two decades, over 50 million units of the drive have been produced and installed for almost every major manufacturer, down to the mid-range passenger car segment.