) ALIO Industries’ ultra-precise motion control systems are indispensable in a variety of health and life science applications due to their unparalleled accuracy, reliability, and repeatability. These systems enable ground-breaking advancements by ensuring meticulous manipulation and positioning, vital for the success of genome sequencing, the manufacture of medical and clinical devices, and digital pathology.

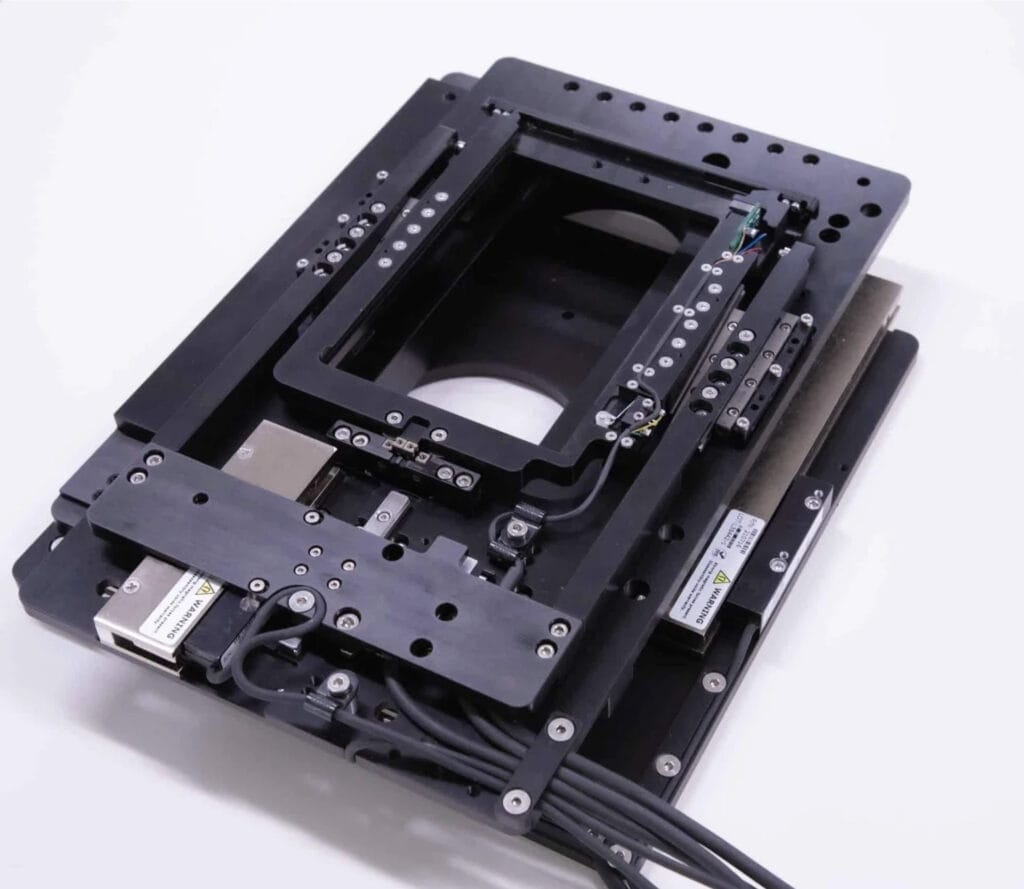

Genome Sequencing. For genome sequencing — where even minor variations in the stage velocity or drift of the trigger clock can cause poor imaging — ALIO is renowned for providing market-leading motion control solutions. The company promotes increased throughput, reduced run time, and lower costs per run coupled with high quality and repeatable imaging by creating a smoother, continuous scan process using a monolithic XY stage and a low friction vertical Z-stage for focusing. Z focusing can compensate for both variation in the sample and the flatness variation of the XY stage. The ideal technology for achieving the optimum move and settle time is a linear motor stage with a magnetic counterbalance. The linear motor allows for maximum acceleration and deceleration and provides exceptional position stability.

Manufacture of Medical and Clinical Devices. Accurate motion control is also crucial in manufacturing medical and clinical devices like diagnostic imaging machines and video endoscopes. For such exacting applications, ALIO provides the AngularesTM Hybrid Hexapod®, which features precision crossed roller bearing guides, optical incremental or absolute encoder feedback on all axes, linear motor and/or servo ball screw drives, unlimited programmable tool center point locations and coordinate offsets, and zero backlash on all axes. This makes the AngularesTM capable of unlimited XY travel, Z travel of 62 mm (which can be increased to 208 mm using other tripod models); tip/tilt travel of 60 degrees (+/- 30 degrees) with continuous 360 degree Theta-Z; XYZ bidirectional repeatability of less than +/- 100nm; velocity up to 100 mm/second XY and Z; and less than 10 nanometers linear and 0.1 arc-seconds angular minimum incremental motion.

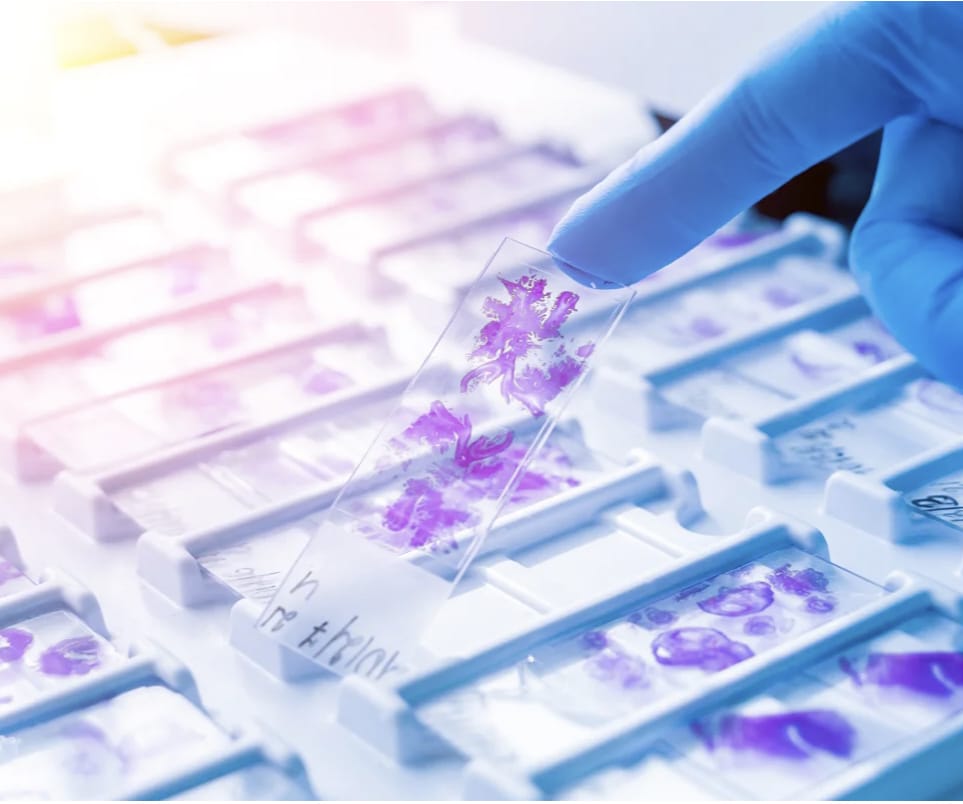

Digital Pathology. ALIO also has a wealth of experience in the area of digital pathology, where the ability to manipulate specimens and imaging devices with unparalleled precision is essential.

Bill Hennessey, President of ALIO says, “ALIO’s motion control systems enable researchers and pathologists to precisely position specimens and imaging components, ensuring accurate and consistent data acquisition. This level of control is particularly critical in applications such as high-resolution scanning, automated sample handling, and image stitching, where sub-micron accuracy is needed. By eliminating motion-induced errors, ALIO’s systems enhance the quality and reliability of digital pathology data, ultimately leading to more accurate diagnoses and accelerating medical research.”

Digital pathology machines demand precise motion control capabilities due to the need for nanometer-level accuracy in specimen scanning and imaging. These systems must precisely position microscope stages and imaging components to ensure that high-resolution images of tissue samples are acquired without motion-induced distortions or artifacts. Any inaccuracies in motion control can compromise the quality of digital slides, potentially leading to misdiagnosis or reduced research validity. Additionally, in automated digital pathology workflows, such as slide loading and sample handling, precise motion control is essential to avoid specimen damage, contamination, or misalignment.

ALIO boasts a range of ultra-precise motion control systems that can cater for even the most demanding digital pathology application.