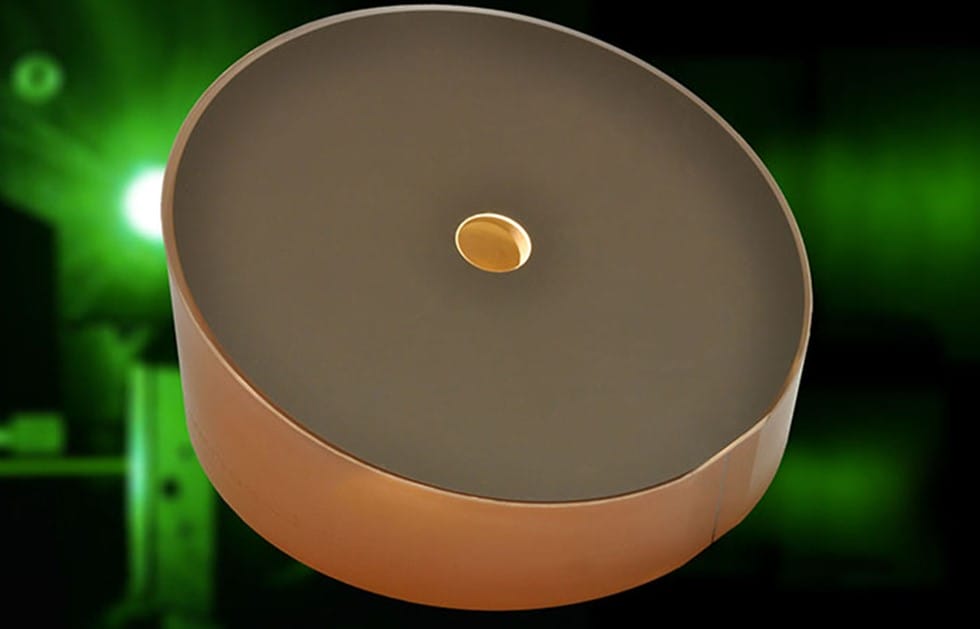

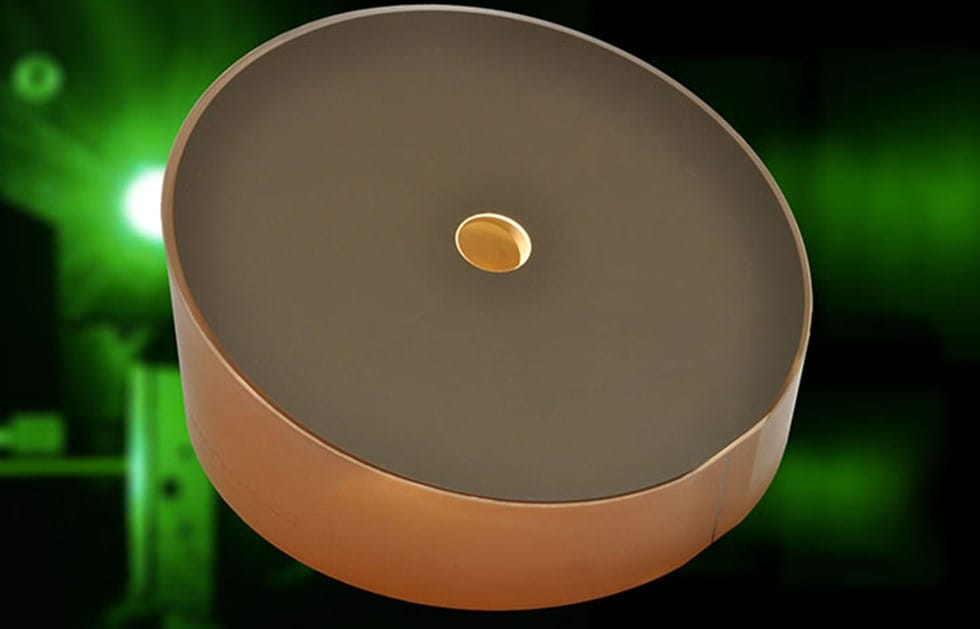

Benefitting from a uniquely stable production facility based deep inside a chalk cliff, Optical Surfaces Ltd’s skilled engineering team are world renowned for producing off-axis parabolic mirrors with surface accuracy, surface microroughness and surface slope errors at the limit of what is possible.

Drawing upon decades of experience – Optical Surfaces Ltd. is regularly selected by leading laser research groups including AWE, ELI, LULI, and CLF Rutherford to provide ultra-smooth focusing mirrors and other related optics for the most demanding high-power laser applications.

Wayne Harris – Managing director of Optical Surfaces commented “Few companies in the world can produce off-axis parabolic (OAP) mirrors of sufficient quality to enable Petawatt and Zettawatt lasers to focus their massive energy down onto targets only a few microns in size. The laser-plasma interactions under these conditions can produce energetic beams of electrons and protons as well as bright, coherent sources of X-rays enabling researchers to address fundamental questions in astrophysics and plasma physics”.

Continuing Mr Harris said “OAP’s offer the advantage of an unobstructed aperture and access to the focal plane. In addition, due to their completely achromatic performance, they are especially suitable for broadband or multiple wavelength laser applications. Many optical and system designers favour OAPs as they often provide the most cost-effective answer without any compromise in performance and present the ideal solution to many high-power laser beam focusing applications”.

To learn more about ultra-smooth off-axis parabolic mirrors for high energy laser research please visit https://www.optisurf.com/index.php/products/off-axis-paraboloids/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com.

Optical Surfaces Ltd has been producing optical components and systems for more than 50 years and is now accepted as one of the world’s leading manufacturers of high-precision optics for high power laser research facilities. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant, and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.

Extremely durable, high performance coated mirrors for use with high power femtosecond lasers (courtesy: Optical Surfaces Ltd.)