A global packaging company is monitoring VOC emissions (volatile organic compounds) continuously at its facility in Ireland – primarily to manage and improve the plant’s environmental performance and to demonstrate regulatory compliance. Due to a changeover in equipment, a short-term requirement arose for VOC monitoring with a flame ionisation detector (FID) that was hired from Signal Group in the UK.

Feedback from the project indicated that the Signal analyser proved to be accurate and reliable, and provided the packaging manufacturer with a problem-free transition as it updated its monitoring regime. However, there was a delay in the work, and the rental of the Signal analyser was extended for several months.

The plant’s VOC emissions arise from printing and laminating processes, and are treated by an oxidiser, after which an FID analyser measures the total organic hydrocarbon content post-oxidation. By monitoring the emissions continuously, the plant’s operators are able to refine their processes to improve efficiency, and to minimise emissions.

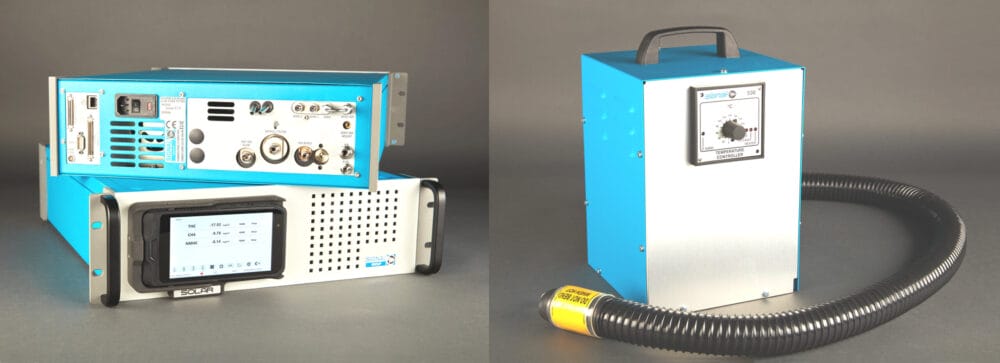

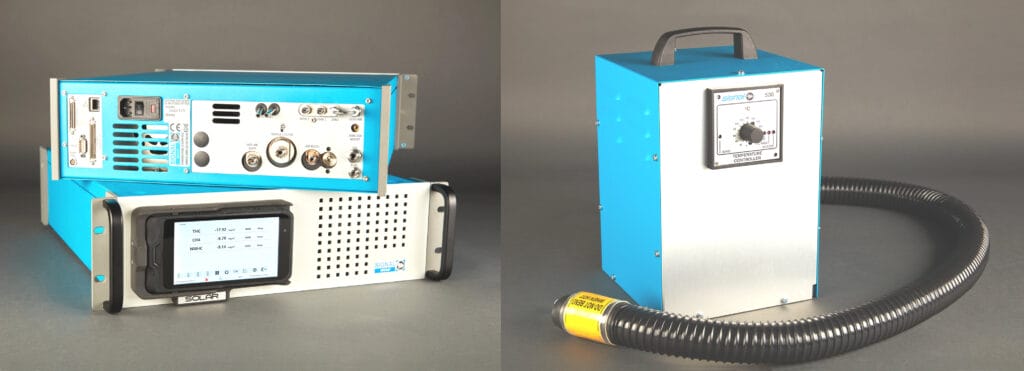

The hired Signal equipment included a heated FID analyser, a heated line with controller, and a filter. “We manufacture all of these items, whihc means that the complete system is delivered ready-to-go, so that clients can be assured of compatibility, accuracy and reliability,” explains Signal MD, James Clements. We have hundreds of these systems in operation all over the world, so our staff are highly skilled and experienced in delivering support.

“As the world strives to meet the COP28 goals, manufacturers are looking to reduce their carbon footprint, as well as the carbon footprint of their supply chains. Lowering VOC emissions is one of the ways in which companies can help achieve these critically important objectives.”