(December 14th 2023, Muellheim, Germany) For companies looking for high volume production of zero failure rate precision metal parts and components, micrometal GmbH is announcing refinements it has made to the photo-chemical etching (PCE) process which takes it to the next level in terms of tolerance attainment.

Traditional PCE offers unparalleled precision and consistency when compared to standard metal processing technologies, which is crucial when manufacturing high-quality metal parts in today’s technologically advanced industries. Additionally, the process is cost-effective and efficient, allowing manufacturers to meet increasing demand for complex and detailed components quickly and at a lower cost. However, micrometal is constantly innovating the process, and is now able to claim process parameters at the next level when compared to traditional PCE processes.

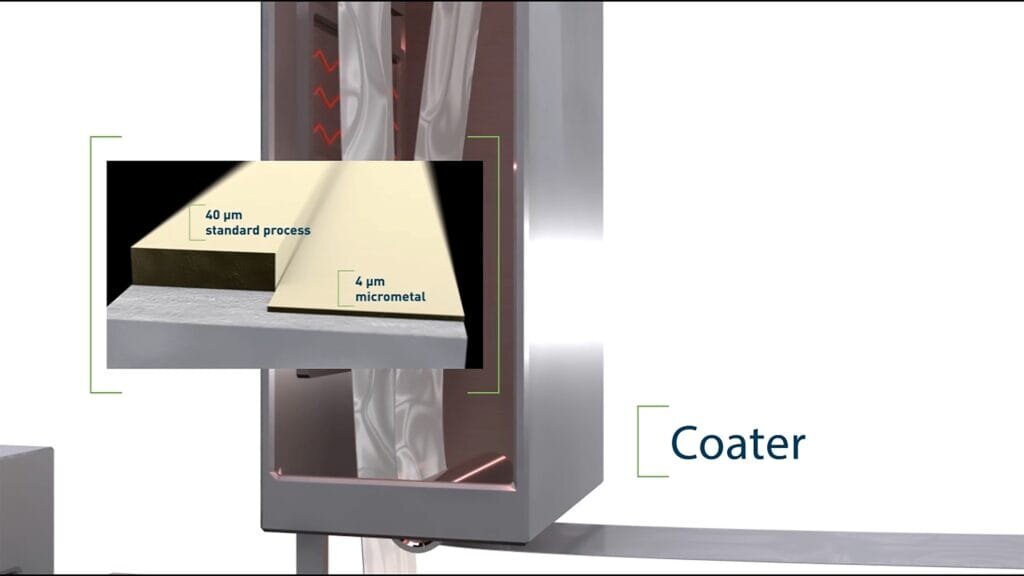

One key reason for this is the company’s patented use of a special liquid resist system. Jochen Kern, Head of Sales and Marketing at micrometal explains, “Through the use of our liquid resist system, we can obtain ultra-thin (2-8 micron) photoresist layers enabling a higher degree of precision in the chemical etching process. It allows the achievement of extremely small feature sizes of 25 microns, a minimum hole diameter 80% of the material thickness, and single digit micron tolerances repeatably. In addition, along with the company’s optimised exposure system it can avoid the parallax problems typically associated with alternative PCE processes.”

Traditional PCE uses relatively thick dry film resist which can compromise ultimate part precision and the tolerances that are available, and it is only able to achieve 100-micron feature sizes and a minimum hole diameter of 100-200% material thickness. micrometal’s next generation PCE process enables ultra-precise contours to take shape, and as such the company can produce metal parts with unique features and a level of complexity that cannot be matched.

Kern continues, “Because of this we consider our PCE process to be an enabling technology, producing hitherto impossible metal parts and components, and therefore driving industrial innovation for customers.”

micrometal’s liquid resist in its PCE process is a crucial innovation that elevates the precision and quality of metal part fabrication. The resist acts as a barrier, protecting selected areas of the metal during the etching process, and its liquid form allows for a uniform application, even on complex geometries. This uniformity is pivotal for achieving tight tolerances, ensuring that each part meets exact specifications with high fidelity.

Liquid resist outperforms traditional hard masks and dry films, especially when dealing with very fine features. Its ability to coat smoothly over surfaces without the risk of voids or defects leads to a more precise and detailed etching. As a result, manufacturers can produce parts with tighter tolerances, which is essential for high-stakes industries such as semiconductor manufacturing, precision engineering, and medical device production, where even minute deviations can compromise the functionality and safety of the final product.

Kern concludes, “By integrating micrometal’s liquid resist, manufacturers gain a competitive edge through enhanced precision, reduced failure rates, and the ability to meet the rigorous demands of advanced technological applications. We are constantly refining the PCE process which we see as having enormous value in the stimulation of innovative parts and components across industry, and invite engagement from all manufacturers looking to take the next step in the production of geometrically complex, highly functional, and innovative metal parts and components.”