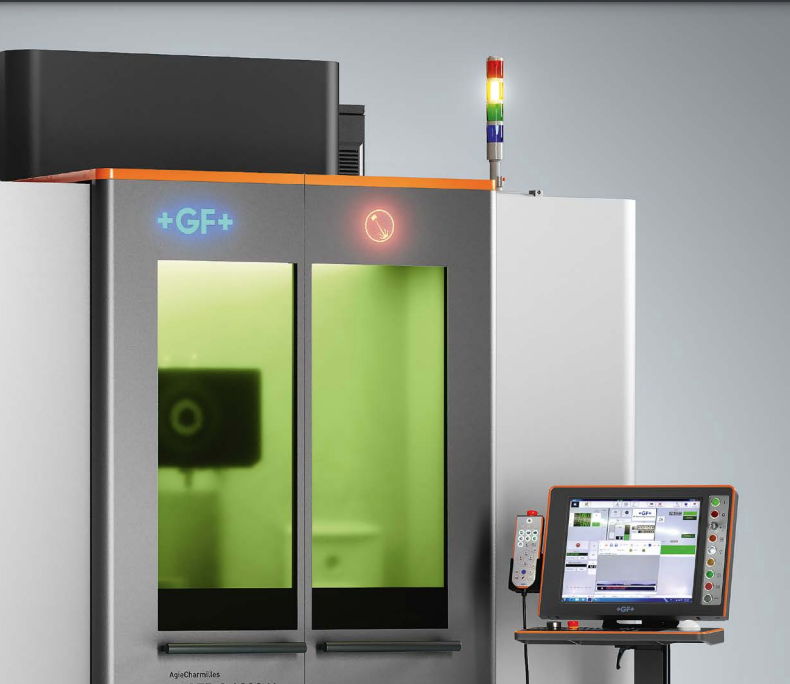

Fimark announces a significant advancement in their technology as they upgrade the power output on their GF Machining Solutions’ state of the art L1000 5 axis laser texturing machine.

This upgrade has doubled the machine’s power from 50 to 100 Watts, resulting in increased processing speed and throughput. As a result clients will benefit in several ways:

Increased Workload Handling:

The enhanced throughput enables Fimark to handle larger workloads, accommodating projects of a larger scale than before.

Streamlined Production:

Quicker processing times and increased throughput streamline the overall production process, reducing bottlenecks and enhancing overall workflow efficiency.

Competitive Edge:

With faster processing and increased throughput, clients gain a competitive edge in the market by delivering products more efficiently, potentially attracting more business opportunities.

Adaptability to Industry Demand:

Clients can respond more effectively to changes in market demand, adapting their production schedules and designs to align with industry trends and preferences.

Consistent Quality: Despite the increased speed, Fimark’s commitment to precision ensures that the quality of textured surfaces remains consistently high, meeting or exceeding client expectations.

Overall, the increased processing speed and throughput not only contribute to operational efficiency but also empower clients with the tools to stay competitive and agile in a dynamic market environment.

Not sure whether your business could benefit from this technology? Here are some examples of applications across industries:

Automotive:

With increased processing speed, Fimark offer a competitive edge in laser surface processing for automotive, particularly in texturing moulds for interior and exterior car parts and metal components like door handles, fascias and switch bezels.

Medical Implants:

The clean, digital surface structuring process provided by Fimark’s state of the art process ensures high-quality surface structuring for medical implants and improves osseointegration performance on 3D surfaces.

Mould Tools:

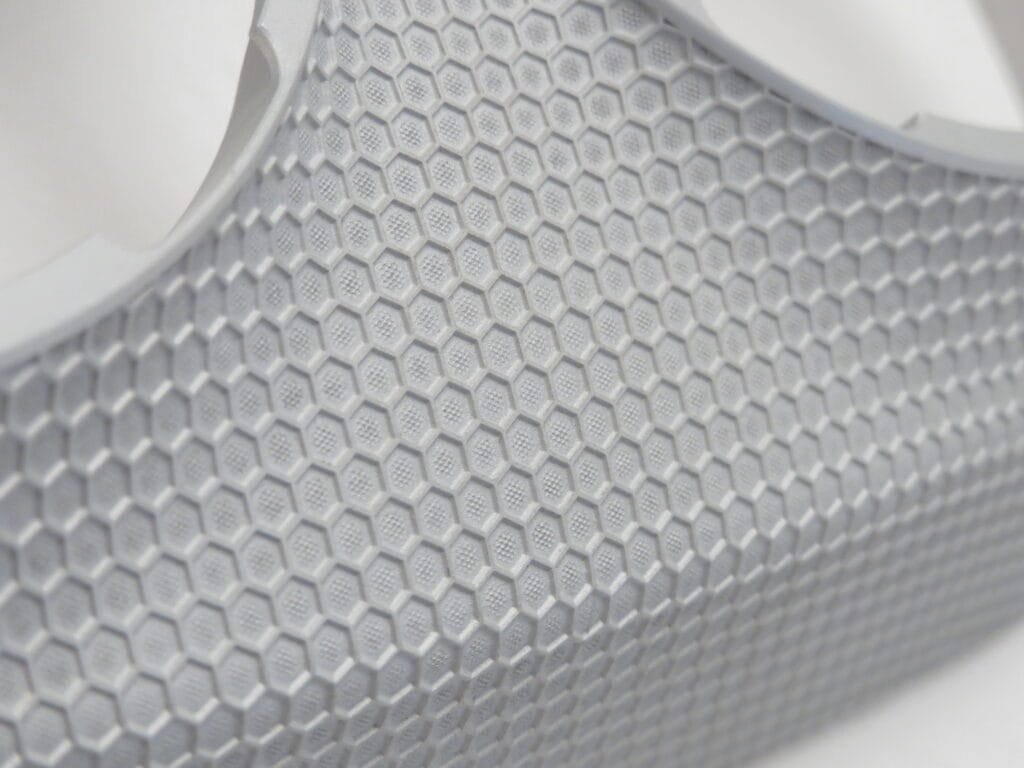

Fimark’s advanced Laser 3D Texturing technology reduces mould lead-time while creating intricate fine textures and engravings.

Watchmaking Innovations:

Precision engineering meets watchmaking as Fimark’s upgraded technology aids their intricate engraving services on watch dials. Their leading CAD technology on the L1000 proves particularly beneficial when precise depths of engraving are crucial ahead of a vitreous enamelling process.

Geometrical Patterns:

Fimark’s CAD software on the L1000 guarantees texture continuity between parts, offering precise control over the orientation and size of each detail, catering to diverse geometrical pattern demands.

PET Blow Moulds Integration:

Fimark’s technology achieves a new level of efficiency with PET blow moulds, eliminating manual intervention and ensuring a blemish-free, precise outcome.

Thinking of enquiring? These are just some examples of applications across industries. Contact the Fimark team today to explore how this upgraded solution can elevate your industry standards.

Connect with our team today: