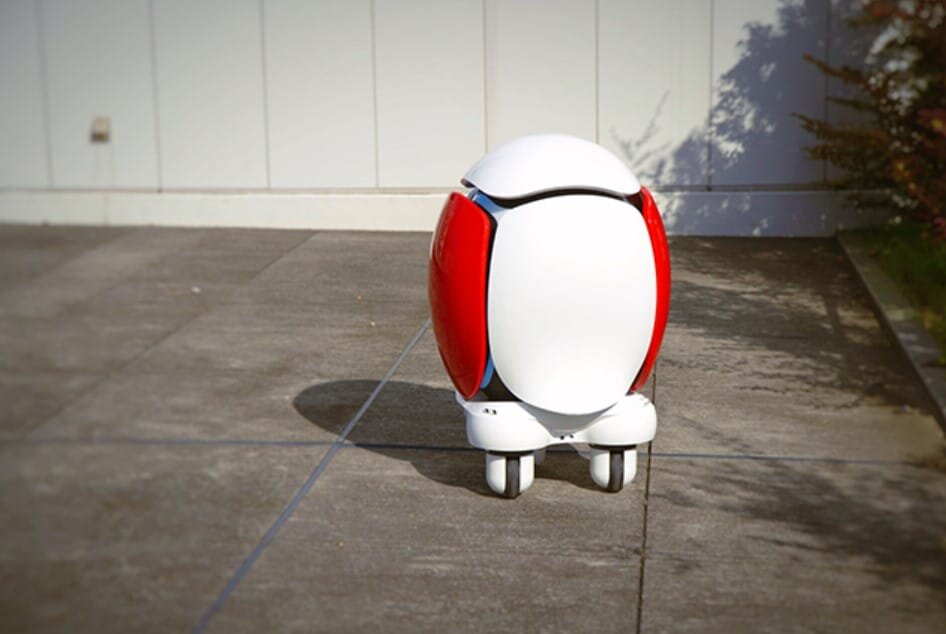

As part of a drive to get robots into more and more workplaces, operating side-by-side with humans, a team of expert development engineers at global motion control specialist NSK have come up with a novel way to improve the mobility of collaborative robots (cobots): the NSK Active Caster. This innovative omnidirectional motorised drive unit, which is ready for use in a diverse range of cobot and service robot applications, could soon come to the assistance of countries facing ageing populations and labour shortages.

NSK‘s Active Caster can move in all directions, carry heavy loads and traverse gradients

NSK‘s Active Caster can move in all directions, carry heavy loads and traverse gradientsThe NSK Active Caster wheel unit is suitable for use in close proximity to people. Smart, quiet and compact, Active Casters fitted to service robots are currently undergoing field tests and could shortly play a role in workplaces around the globe. Service robots that interact with humans is a very new field, one with direct benefits for a number of industries, including logistics and medical.

Hospitals and care facilities, for instance, require workers to perform many physically demanding tasks in a timely manner to aid the recovery of patients. Here, Active Casters could act as service robots by automating medical carts, transporting medical supplies, moving gurneys and reducing the overall workload in these busy environments.

This capability could prove vital in many established economies around the world suffering from ageing populations and labour shortages. In such locations, cobots and service robots taking advantage of Active Casters may soon become necessary to automate repetitive and manual tasks, enabling humans to focus on higher value work activities.

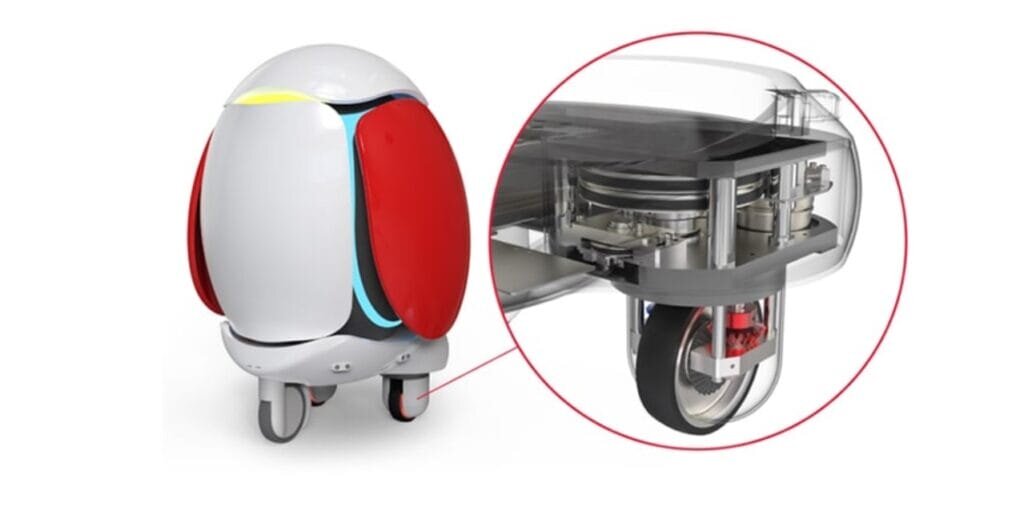

The NSK Active Caster is an omnidirectional motorised drive unit for cobot and service robot applications

The NSK Active Caster is an omnidirectional motorised drive unit for cobot and service robot applications

Potential applications also exist in wider society, helping people suffering with limited mobility for instance. Here, Active Casters could become part of a robot ‘suitcase’ to make it easier for people to travel, or a moving cart that doubles as a walker to help carry things around the house. The programmable walker could move out of the way and return when convenient, giving the user more space when sitting down without having to worry about keeping it within reach.

At present, the NSK Active Caster is undergoing repeated operational tests in a laboratory featuring various surface environments, such as uneven floors, carpets, bumps and slopes. The team wants to ensure the product can facilitate motion in all directions, carry heavy loads and traverse gradients over the most challenging of terrain. Active Casters feature two motors per wheel, and control steering and motion through the difference in their rotational speeds. Moving forward, the company’s development engineers will continue to evolve the design by applying NSK’s strengths in bearing and lubrication technology.

NSK Active Casters feature two motors per wheel

NSK Active Casters feature two motors per wheel

Balancing the performance-to-cost ratio is a key focus of the development process. Ultimately, the team is using technology and know-how cultivated in many fields of research and development to drive this ambition.

NSK has been manufacturing bearings for more than 100 years, helping the company nurture close ties to cutting-edge fields such as cobots and service robots. In the Active Caster project, like many projects before, NSK will continue to communicate closely with its customers and make every effort to devise solutions that add value to industry and society.