~ What to consider before embarking on an ASIC design project ~

Manufacturers ready to make the most out of a custom IC can be keen to jump into development. But before putting any pen to paper, it’s vital to ensure you choose the right partner for your design project. In this article, Ross Turnbull, Director of Business Development and Product Engineering at ASIC design and supply company Swindon Silicon Systems, explains what to consider.

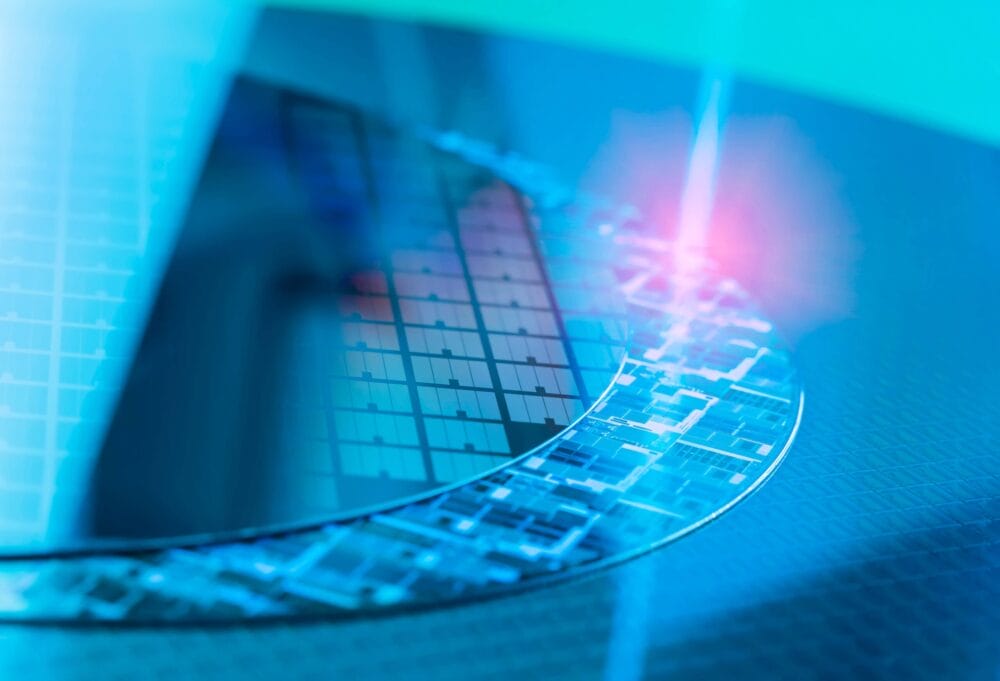

For manufacturers looking to gain both a technical and commercial edge over their competition, an Application Specific IC (ASIC) could be the ideal solution. An ASIC is a chip that has been designed specifically for its designated application. As a result of the bespoke design approach, an ASIC can offer superior performance and functionality over off-the-shelf solutions.

But while the benefits of an ASIC may be well understood, less so is the process of choosing the right ASIC partner. So, what should businesses consider when searching for a custom IC partner?

Engineering expertise

The first step is to identify whether the IC designer can deliver a product that meets application requirements. The strength of an ASIC comes from its bespoke design approach, with the chip built to fit customer expectations. If the designer doesn’t have the expertise to fine-tune performance at such a high level, the resultant chip likely won’t be as successful.

For example, if you need an ASIC solution that combines both analogue and digital functionalities — typically ICs are used for analogue to digital signal conversions — you’ll need to look for a mixed-signal designer. A mixed-signal specialist can combine analogue and digital technologies on a single device without corrupting the signal integrity of either domain. The result is a high-performance chip in a small, low-cost package.

It’s also worth finding out if the IC designer has experience working in your application sector. An IC designer familiar with your particular industry will make achieving regulatory compliance a much easier process. Sensitive markets where safety and precision are critical will often require the product to undergo strict certification procedures. In the automotive industry for example, relevant safety methodologies include AEC Q100 and ISO 26262. As part of the ISO 26262 certification, it’s also necessary to determine the Automotive Safety Integrity Level (ASIL), essentially a hazard and risk assessment for each individual component in the vehicle.

Certification criteria should be considered as early as possible in the design stage to ensure the final product meets demands; choosing an ASIC supplier that understands these helps to ensure that the delivered product is 100 per cent compliant, avoiding the need for costly redesigns.

In-house capabilities

Another element to consider is how much of the IC design workflow can be done in-house. Choosing a supplier that offers a full turnkey ASIC service, including initial specification, development, packaging and test means that the customer has a single point of contact and therefore one person of responsibility overseeing their project. If there are any issues, either on the customer or design side, communication is far simpler.

And a process managed entirely in-house will likely be much more efficient, with quicker production lead times and reduced costs. The result of this is a high-quality ASIC solution that meets specification and is delivered on-time.

A robust supply chain

The last key point to consider is the supply chain. An IC designer might be able to deliver one batch of high-quality product on time, but what if one batch isn’t enough? In most cases, embarking on an ASIC design project is the beginning of a much longer relationship between customer and supplier. For many manufacturers, it could also include shipping ASIC chips worldwide.

To avoid being left vulnerable, it’s essential to look for a supplier that can deliver long-term. This protects your business from being stuck with an ASIC design and no-one to produce it; or, worse, not possessing your IP at all and having to go through the entire ASIC workflow again.

When thinking about the long-term, obsolescence is likely to be a key concern for manufacturers. One of the main benefits of a custom IC over off-the-shelf solutions is obsolescence protection: production of a standard IC can be halted at any time at the manufacturer’s discretion, but not so with a custom IC.

However, there is still a risk of obsolescence, typically due to the silicon process becoming obsolete. A reputable ASIC designer will take care to design the IC solution using a process that matches the required longevity of the product. But in the unlikely event obsolescence does occur, they must be able to work quickly with the customer to find the right solution for them.

Key points to check are how long the ASIC supplier has been in the industry, its supply chain management policies and obsolescence protection. Swindon, for example, has been a market leader in ASIC design and development for more than 50 years. With a dedicated account management team, Swindon is in constant contact with customers to ensure there is enough Work in Progress (WiP) in the production line to meet customer forecasts and requirements. And as an ASIC designer offering an FTK solution, Swindon’s in-house Quality Assurance Department is constantly monitoring product quality and yields to ensure on-time delivery of a superior product.

When it comes to protecting against obsolescence, Swindon works on a four-pronged approach to ensure the ASIC solution is available for the entirety of the product’s lifetime. This not only includes careful consideration of the ideal silicon process at initial design, but also extensive support beyond product delivery. Swindon will work to ensure there is never a gap in IC availability in the most cost-efficient way for the customer. Regardless of the route taken, it’s always one that is agreed mutually.

Manufacturers keen to unlock the benefits offered by a custom IC can be tempted to jump headfirst into a project. But it’s crucial to take the time to find the right supplier for your product. Industry experience, in-house capabilities and whether the company can deliver a long-term solution are all key considerations to make before beginning any ASIC design project.