Aerospace automation specialist Loop Technology has signed a deal with FANUC UK for seven new robots – including four units of the largest industrial robot ever to be ordered in the UK, the FANUC M-2000iA/1700L.

Renowned as the strongest long-reach robot in the world, three FANUC M-2000iA/1700L six-axis units will be delivered to the University of Sheffield Advanced Manufacturing Research Centre (AMRC) for its new innovation facility in South Yorkshire. This is part of Project Compass (Composites at Speed and Scale), a larger £80 investment which includes an aerospace manufacturing R&D project delivered by a consortium of partners including Boeing, Loop Technology, Spirit AeroSystems and the AMRC. The Loop/AMRC deal also encompasses two further FANUC M-2000iA robots: a 1200L and a 900L model.

As part of a separate project, another 1700L model, along with an additional 900L unit, have been ordered by Loop Technology to form part of a high-rate composite preforming cell for a North American aerospace client. This brings the total number of FANUC M-2000iA six-axis robots commissioned by Loop Technology for this latest order to seven.

Loop Technology’s FibreLINE is a high rate preform manufacturing system for the aerospace sector.

Decarbonising the aerospace sector

The aerospace manufacturing sector is booming, with 3,850 aircraft orders being placed in 2023 – a global record, according to ADS, the trade association for the aerospace, defence, security and space sectors. However, there is also currently a global aircraft backlog of 15,753, which is the largest on record. Increasing the level of automation in aerospace manufacturing is one of the main ways to increase productivity and help to reduce this backlog, while also tackling one of the sector’s main challenges – decarbonisation.

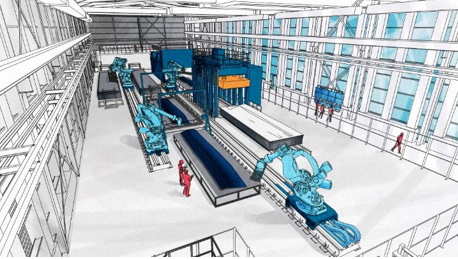

The new AMRC innovation facility in Sheffield has been developed to help solve composites manufacturing challenges in order to meet future demand for lighter commercial aircraft and help the aviation industry reach net zero. It aims to de-risk and develop high rate sustainable structures, with the potential to reduce large component process times from around 40 hours to approximately four hours. The facility is expected to be completed by the end of 2024.

The building will be home to a raft of state-of-the-art equipment secured through a £29.5m grant from the Aerospace Technology Institute (ATI) Programme to support new capabilities, technologies and processes to reduce cost, waste, production time and associated carbon emissions.

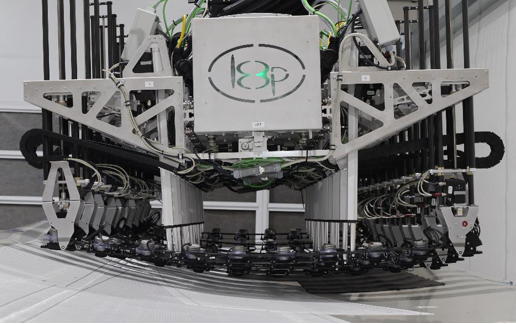

FANUC’s six-axis M-2000iA/1700L is the strongest long-reach robot in the world.

Boosting productivity

The five FANUC M-2000iA industrial robots that have been ordered by Loop Technology for the AMRC facility will form part of Loop’s proprietary high-rate deposition cell, known as FibreLINE. This state-of-the-art high rate preform manufacturing system, with FibreFORM at its centre, can pick composite sheets (plies) and form them into complex 3D double curvature profiles before placing them onto a tool, inspecting them and heat staking them ready for the next stage of the production process, at a rate of up to 200kg an hour. Traditional methods typically operate at 40kg/hr, so this is a significant improvement. Meanwhile, the National Composites Centre, which uses a different configuration of FibreLINE that includes FibreROLL, has stated they are on track to deliver 350kg/hr.

AMRC CEO Steve Foxley pictured at the groundbreaking for Project Compass with research partners: Todd Citron, Chief Technology Officer of Boeing; Sean Black, Senior Vice President and Chief Engineer, Engineering and R&D at Spirit AeroSystems; and Alun Reece, Managing Director at Loop Technologies.

Market-leading size and reach

Loop Technology has also ordered two further FANUC M-2000iA robots to form part of a separate FibreLINE system, for a key North American aerospace customer looking to carry out R&D applications. Once built, the entire FibreLINE system will measure more than 20m in length. It will centre around FibreFORM, a 3D double curvature preforming gripper that weighs more than one tonne, meaning that heavy-duty industrial robots with a high payload and long reach are essential. With a 1.7 tonne payload capacity and 6.2m stroke, the M-2000iA/1700L provides maximum flexibility on operations involving large and heavy objects. Capable of lifting and positioning an entire car body, it is officially the strongest long-reach robot in the world, making it the ideal choice for Loop Technology both for their North American aerospace client, and for the AMRC innovation facility.

“Being aero structures, the parts that are being manufactured on our FibreLINE systems are extremely large,” explains Alun Reece, Managing Director of Loop Technology. “These two projects therefore both require robots with high payload and reach capabilities to access all the areas necessary in order to carry out deposition or inspection activities. While we could have used precision gantries to deploy our end effectors, they limit access to the cell area due to requiring two rails on which to carry the gantry bridge. In contrast, the M-2000iA robots are mounted on a single axis rail, providing clear access from one side. They are our clear robot of choice for such projects.”

An artist’s impression of the new research facility.

A solid partnership

Oliver Selby is Head of Sales for FANUC UK and has worked alongside Loop Technology for a number of years, helping to increase innovation in the aerospace sector. “We have been proud to have Loop Technology as one of our system integrator partners for the past five years,” he states. “Their solutions, such as the FibreLINE and its constituent parts – FibreFORM (ply manipulation), FibreTACK (ply tacking) and FibreEYE (inspection) – are helping to increase automation uptake among aerospace manufacturers. Given the labour shortage within manufacturing as a whole and the extensive aircraft order backlog, higher levels of automation are essential to increase productivity and ensure the industry continues to thrive in the coming years.”

Alun Reece adds: “Innovations in robotics around scale, precision and collaborative working are opening up new opportunities for aerospace manufacturers all the time. Whether in high rate preforming systems, fibre placement, or assembly operations such as drilling, fastening, sealing or automated inspection applications, the versatility offered by modern robotics is redefining the way tasks are performed, helping to drive down aerospace manufacturing costs while driving up quality.”