~ FAULHABER releases new Motion Manager 7 ~

Where positional accuracy and motor movement control is key, you’re sure to find a motion controller. But achieving controller configurations matched perfectly to the application requires specialist software. As the UK and Ireland distributor for FAULHABER, Electro Mechanical Systems (EMS) now offers the newly upgraded Motion Manager 7 to help customers maximise motor performance and efficiency.

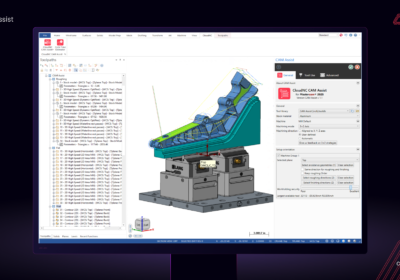

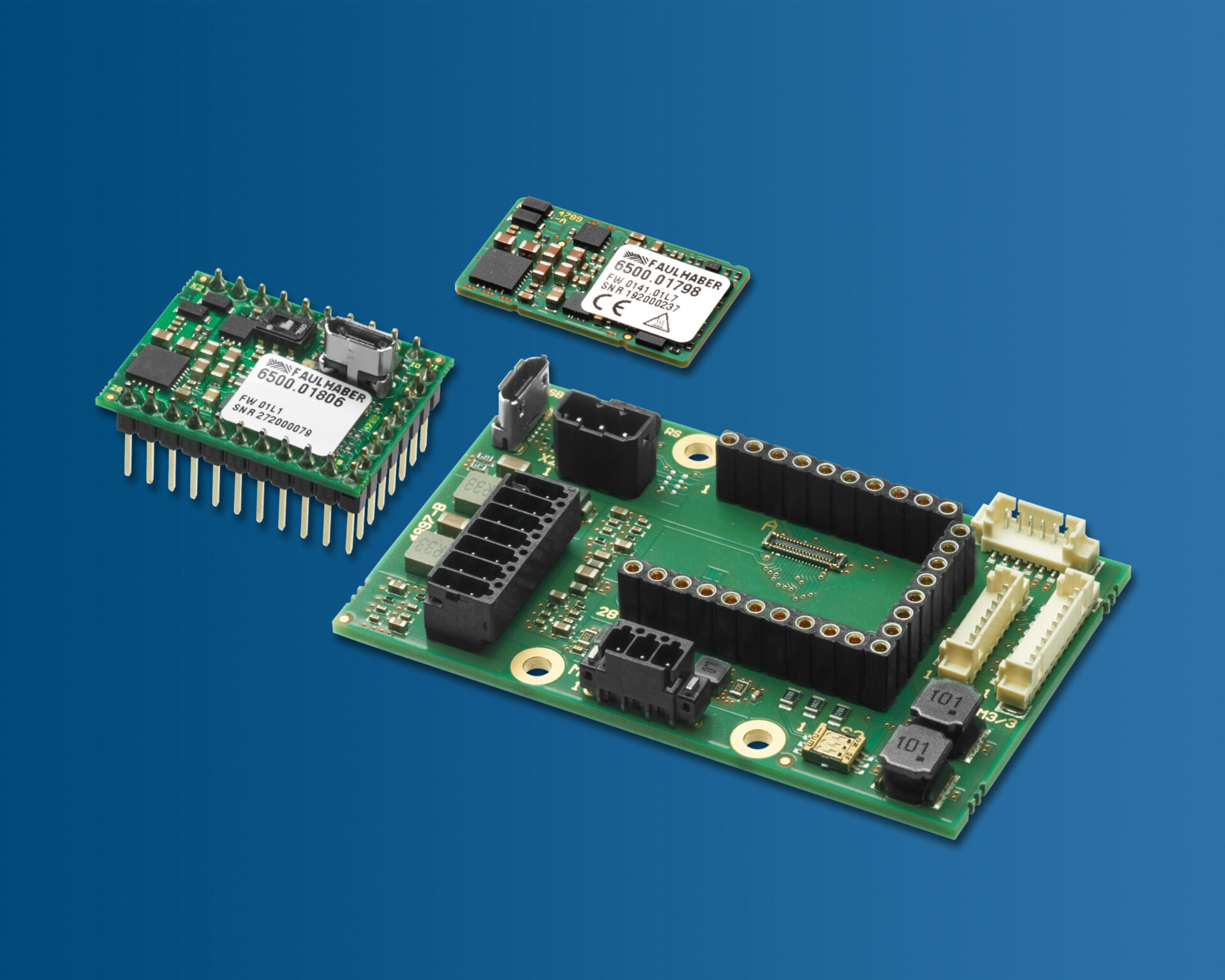

Enabling easy motion controller operation and configuration in just a few clicks, FAULHABER’s Motion Manager software has been designed to help customers maximise drive system performance and positioning accuracy. Released to complement the latest V3.0 family of motion controllers, including the MC 3001 B/P and MC 5010 models, the upgraded Motion Manager 7 software offers several benefits over its predecessor.

The first upgrade is a newly designed area for easy commissioning and configuration of the drive systems. An expanded toolset is now available to control and observe drive behaviour, as well as provision of a development environment for sequence programs and a maintenance area for diagnostics and firmware updates.

Setting up of the drive system within Motion Manager 7 is simple. To begin, users can manually enter their motor’s details or simply choose from FAULHABER’s product database. Any additional components such as precision gearheads and encoders can also be specified at this stage. The selected drive is then configured accordingly and can be safely operated without load.

Using Motion Manager 7, it’s possible to set the application and environmental parameters necessary for successful integration of the drive electronics. Current, speed and position limits to protect both the electronics and the motor from overloading can be determined at this stage.

Control parameters may be carefully adjusted to improve motor dynamics for an optimised drive system performance. To observe drive behaviour, the Motion Manager 7 offers graphical analysis with axis scaling as well as a status display of actual values. These recordings can then be exported either as a bitmap file or as a text file CSV for further external processing.

Projects created for individual drive systems can be saved and shared across PCs, enabling work to be carried out across multiple desktops as and when required. Several different interfaces are supported by the software including CAN (HMS-IXAAT, Peak) and COM (RS232). Controller connection via USB is also supported with specialist drivers, installed automatically within Motion Manager 7.

“Many industrial automation technologies such as pick-and-place systems and conveyer belts rely on drive systems with precise positional control. Motion controllers are often key to achieving this level of accuracy,” explains Dave Walsha, sales manager at EMS. “Regardless of the type of motor being used — be it brushed, brushless or linear — the addition of a motion controller is crucial. Not only does it help protect the drive from overload damage, but controller integration also greatly improves motor dynamics, accuracy and efficiency.”

Motion Manager 7 is now available to download for free from the FAULHABER website in both English and German. For exclusive access to FAULHABER’s range of drive electronics in the UK and Ireland, get in touch with EMS today.