Heat treatment processes are a crucial component of many manufacturing processes, but precise control of temperature requires more than just heating control. This is where the thermal loop comes into play. Thermal loop solutions have become increasingly popular for achieving improved temperature control and consistent outcomes, but what exactly does the thermal loop mean? In this article, Andy Selvy, chief system designer at industrial technology company Watlow, offers his insight.

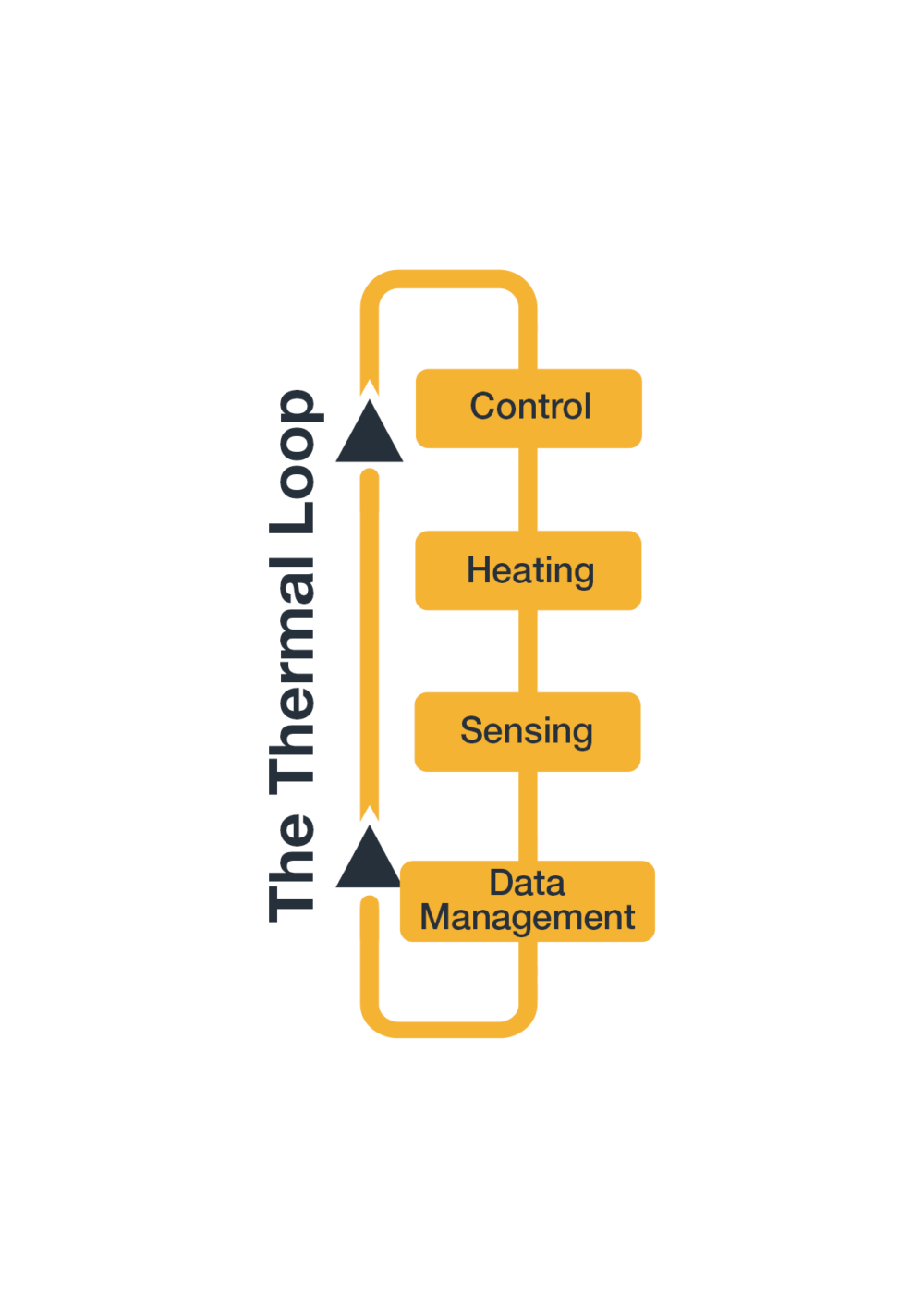

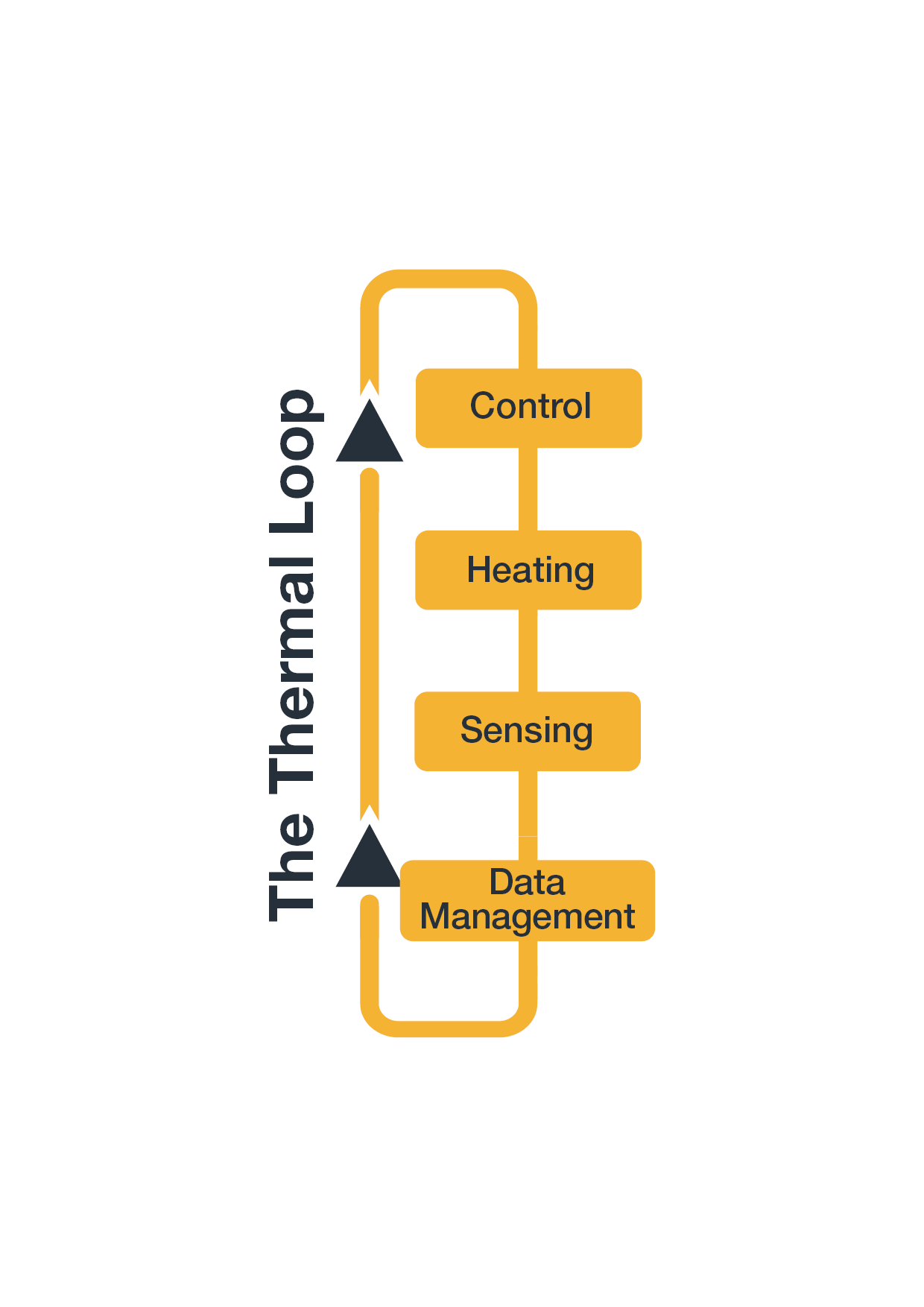

A thermal loop is a system designed to precisely control the temperature of an object, fluid or gas. It comprises a closed loop system with vital components, such as an electrical power supply, power controller, heating element, temperature sensor and process controller. The electrical power supply furnishes the necessary energy for heating, while the power controller modulates the power output to the heating element. Subsequently, the heating element raises the material’s temperature, and the temperature sensor gauges the temperature. Ultimately, the process controller fine-tunes the power output to sustain the desired temperature for the specified duration, ensuring improved temperature control and consistent results. In some cases, a single component can play multiple roles.

For example, with high temperature coefficient of resistance (TCR) materials, it’s possible for a single component to act as both a heater and a sensor, which cuts down on the total number of components and wires needed in the system. Altogether, these parts create a system known as a thermal loop that can maintain process temperatures automatically through time.

How does it work?

A home thermostat is a simple, everyday example of closed loop temperature control. You can adjust the temperature of the range, but this must be done manually. The system does not detect temperature or adjust itself — it only provides heat. A homeowner could set a thermostat and leave it for months, never having to actively direct or control the system, but the system would maintain the same temperature range during that time. They work well for heating our homes, but certainly come with limitations with regards to temperature control.

The limitations seen with traditional thermostats provide a good parallel for understanding the challenges that industries face when it comes to process heating and thermal control. For instance, heaters are typically controlled by consistently monitoring the power being provided. If power can be controlled in a more precise manner, then heaters can be better controlled and heater life can be extended. This often requires going beyond simple “power on or off” switches and introducing advanced forms of power control.

Temperature sensing needs to be done in multiple zones, not just one place. For example, a surface for creating semiconductor chips might need to be divided into several zones so that temperature uniformity can be achieved at each point — much like having a thermostat in every room of your house.

Systems thinking versus component thinking

This is why systems thinking is so important. Even if you find that “best” component — the best heating element, the best sensor, the best power controller — it does not mean that you have found the best component for that particular application and system. Problems often arise not necessarily because of an issue with the right component, but rather the way the entire system has been engineered.

This can include temperature sensors that are either too close or not close enough to the heating elements, which create an unreliable picture of the temperature on a heater surface or within a heated space. Small fluctuations in temperature at the heating surface can lead to “hot spots” which, over time, can cause scorched material accumulations that can foul up the equipment, resulting in equipment failure. Lastly, the power needs and input to the system fluctuate over time, leading to inconsistent heating even when sensors are recording the correct temperature.

Thermal loop applications

There are many applications where the control of thermal processes matters. This includes semiconductor processing, energy generation, materials processing, medical devices and food and beverage equipment.

Within each of these industries are sensitive processes that require varying levels of temperature regulation. For example, when a manufacturing process molds and shaping metal, the equipment needs to maintain a temperature above a certain threshold. But an exact temperature may not be necessary. So, why do we talk in terms of “thermal loops” at all? Why not just talk about heaters, sensors and power controllers themselves? Granted, naming the parts of the thermal loop and understanding their features is easier. But these individual components are just that — components.

Understanding the thinking that goes into choosing the right components, and putting them together, is a far greater challenge. This is where Watlow’s thermal expertise comes in. For Watlow, the underlying concept behind its entire offering is of the thermal loop. Currently, some of the applications where Watlow is solving complex thermal problems include respiratory devices, analytical equipment, oil and gas processing and semiconductor processing.

The thermal loop is an idea that not only gives structure to what Watlow offers, but also contributes to the structure of a thermal system as a whole. Understanding the thermal loop for a given application requires an appropriate understanding of the components in the loop. But more than that, it requires bigger picture thinking that considers how the various components need to work together and how they will be embedded in an application to achieve various goals.

To discover more about Watlow’s thermal solutions, visit the website.