All-round good protection

Packaging units from a variety of different industries require optimum packaging and securing for international transport. In many cases, this is achieved with a fully automated strapping system at the end of the production line. Steel cable carriers from KABELSCHLEPP Metool ensure reliable and precise guiding of all media on these machines, enabling a reliable process and high availability even in tough conditions.

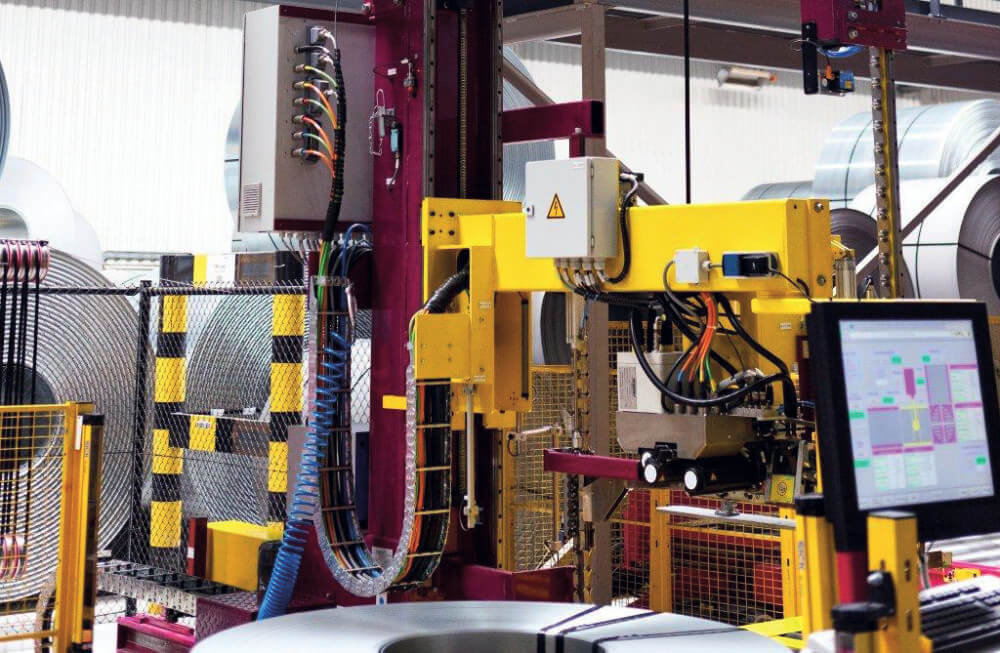

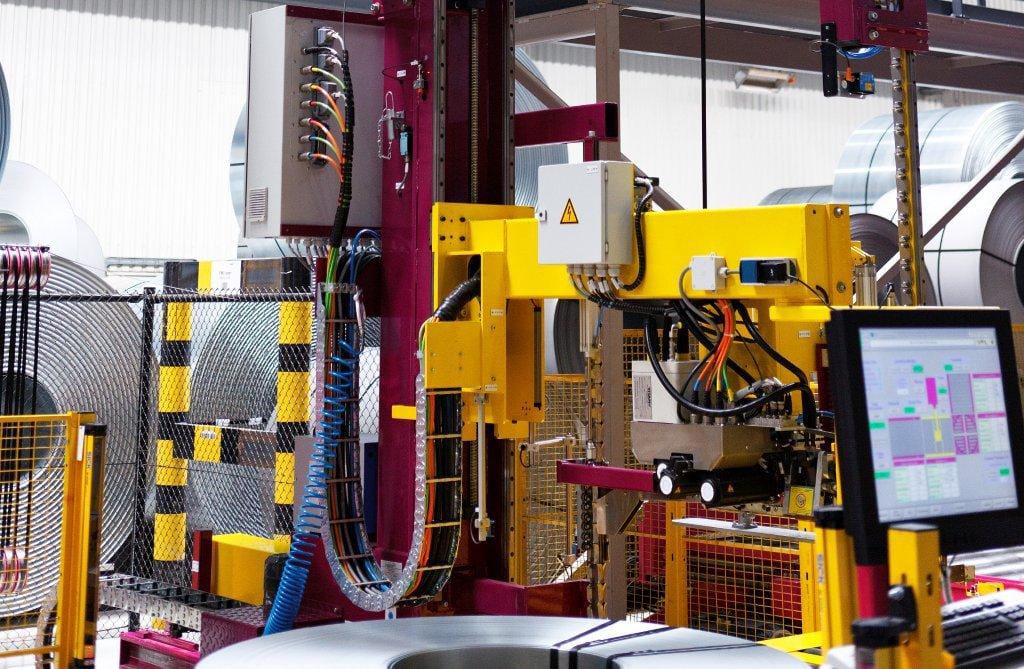

The base frame of the strapping system is movable to accommodate different ring diameters. The cables and hoses run through steel cable carriers from KABELSCHLEPP Metool here as well.

The use of plastic or metal strapping enables reliable securing of transport goods, regardless of whether they are shipped by truck, ship or railway and how many times they are handled under less than ideal conditions. A practical example: Strapping system can be used for packaging slit coils made of steel, copper or other metals. These coils usually weigh several tons and are secured to the pallets individually or in stacks. In preparation for transport, the split coils move through two strapping systems, where steel straps are first placed around the outer circumference and then applied several times through the coil eye.

Strapping as the central step is carried out by the strapping unit, which is flexibly mounted on a boom. In addition to the strapping, this unit also securely fastens the applied plastic or steel “rings”, for example using contactless TIG welding with a tungsten electrode and inert gas.

Cables and gas hoses for the strapping unit are guided in the S 0650 and S 0950 (pictured) steel cable carriers from KABELSCHLEPP Metool.

Steel cable carriers – reliable in any situation

In addition to the cables for the drive motors, the strapping unit mounted on the boom also has to be supplied with the inert gas for the integrated welding system. The steel cable carriers from the S/SX or LS/LSX series from KABELSCHLEPP Metool provide perfect protection for the cables and gas hoses and allow all media to be guided together. The length, width and exact configuration of the cable carriers can be adapted precisely to the specifications of the system at hand.

Steel is often the favored cable carrier material for this type of application as many strapping systems are used in tough conditions, for example in the hot areas of steelworks or in the concrete industry. But plastic cable carriers, for example from the ROBOTRAX series, can also be a good solution. The experts from KABELSCHLEPP Metool use their longstanding experience and comprehensive industry knowledge to help manufacturers find the right solution, so the right cable carrier can be identified quickly and delivered within the shortest time possible.

“KABELSCHLEPP steel cable carriers were developed specifically for extensive unsupported lengths with high mechanical loads or cables and hoses with a high dead weight,” explains Marco Strunk, Industry Manager Intralogistics at TSUBAKI KABELSCHLEPP. “In addition, the steel cable carriers are the first choice for use in rough conditions, which is often the case for strapping machines. High ambient temperatures, as in metal and steel processing, or extreme ambient influences from dust and dirt, as in the concrete industry, pose no problems at all for our durable steel cable carriers.”

For more information: https://tsubaki-kabelschlepp.com/en-gb/products/cable-carriers/lslsx-series/

https://tsubaki-kabelschlepp.com/en-gb/products/cable-carriers/ssx-series/