ALIO Industries is once again redefining precision in motion control with its latest advancements, addressing the growing needs of the 21st-century metrology sector. As industries push the boundaries of accuracy, ALIO’s innovative motion systems, designed to achieve nanometer-level precision, have become the benchmark for OEMs creating the next generation of 3D metrology tools. With the market’s trajectory aimed at ever-finer measurements, ALIO’s commitment to excellence ensures that metrology tools are not only meeting but setting new standards in a field where precision is paramount.

ALIO fulfils the rigorous requirements set by Original Equipment Manufacturers (OEMs) who are developing state-of-the-art 3D metrology instruments. These OEMs navigate a market that is both dynamic and intensely competitive, where the call for increasingly precise metrology answers is constant.

Bill Hennessey, the founder and president of ALIO Industries, highlights several pivotal reasons for the indispensable quality of the motion system. “The system is the cornerstone of exact positioning and movement for the measurement process. Any deficiencies within the motion system, such as mechanical backlash, hysteresis, or non-linear responses, could lead to measurement inaccuracies, undermining even the finest sensors and encoders. By adopting a motion system that matches or excels beyond the quality of these components, such discrepancies are minimized, harnessing the full potential of the high-performance sensors and encoders.”

The stability and accuracy of the motion system also play a critical role in securing the position and orientation of the sensors and encoders during measurements. Vibrations or deviations in the system can skew the readings. It is therefore vital that the motion system delivers the requisite stability and precision to avert these disturbances, preserving the sensors’ and encoders’ accuracy.

Resolution in the motion system directly influences the readings captured by the sensors and encoders. Should the motion system’s resolution fall short compared to that of the measuring components, it becomes the limiting factor in the metrology tool’s accuracy. Hence, a motion system with a resolution on par with or surpassing that of the sensors and encoders is crucial to exploit their capabilities fully.

In instances where multiple sensors and encoders are employed in 3D metrology, their movements must be precisely synchronized. A superior motion system guarantees accurate timing between components, ensuring the metrology tool’s readings are both dependable and consistent. Furthermore, the motion system’s swiftness and responsiveness are essential for precise measurements, and needs to reposition sensors and encoders rapidly and fluidly, eliminating errors or delays that could affect the measurements. This is essential for maintaining accuracy across a range of object sizes and complexities.

With the ongoing advancement of metrology tools, the demand for enhanced precision and accuracy escalates. Employing a motion system that outperforms existing sensors and encoders positions manufacturers to future-proof their metrology tools, making them compatible with upcoming innovations.

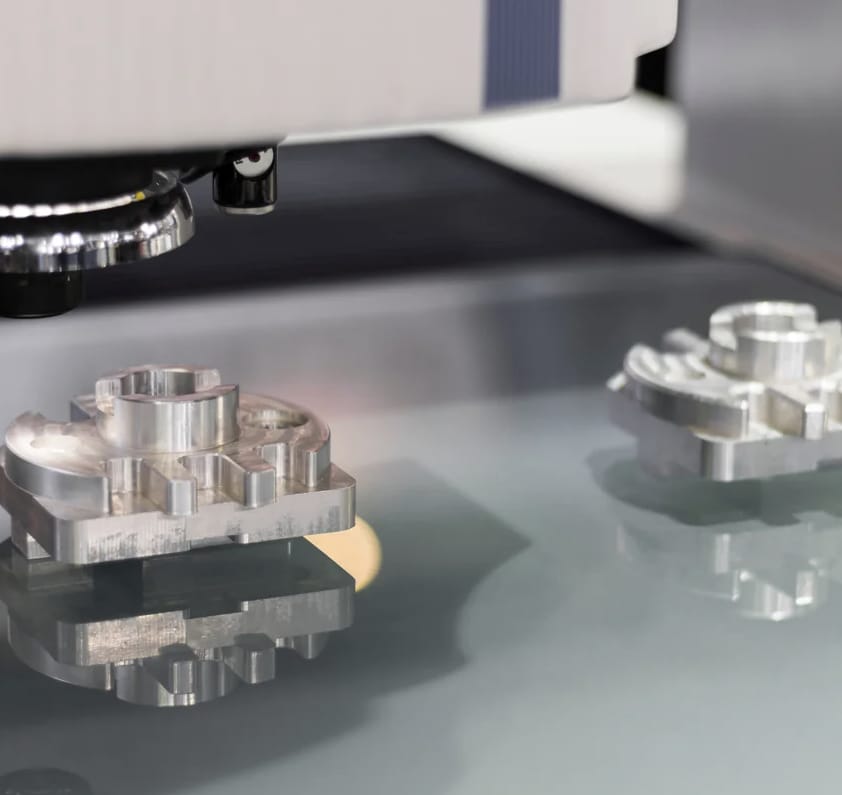

Hennessey continues, “ALIO is ahead of the curve with its advanced offerings such as near air-bearing performance crossed roller bearing XY Nano Metrology® stages, which provide up to 450mm of travel. These stages use DC Servo linear motors, offering motion performance with outstanding precision and repeatability, with 3-Sigma, 6-D (linear, straightness, flatness, pitch, yaw and roll) and bi-directional repeatability of less than +/- 250nm. In other words, the volumetric bi-directional repeatability of any XY point is within a sphere of 500nm or less.”

Such XY Nano Metrology® stages are highly regarded for their precision, accuracy, repeatability, stability, extensive travel range, low maintenance needs, compact design, and versatility, making them the go-to solution for a wide array of industrial and scientific applications requiring sophisticated motion control.

Engage with ALIO Industries to explore how the company is meeting the metrology sector’s demand for ever-increasing precision and unfaltering accuracy in motion control solutions.