Precision liquid flow measurement supports innovation and diversification in the oil, gas and energy industries.

The pressure towards sustainability is pushing the oil, gas and energy sectors to evolve innovative and diverse solutions in a move to create an energy efficient future.

Major transformations within the oil and gas industry in the form of adopting sustainable practices, developing new revenue streams and pushing the boundaries of technology, are being trialled and delivering success. Expanding into new areas such as renewable energy, advanced chemicals and biofuels, is driving innovation and diversification.

Titan Enterprises provides optimised and custom designed liquid flow measurement solutions for oil, petrochemical and green energy applications for OEM customers. These have included bespoke oval gear flow meters for marine fuel flow measurement, monitoring the volume of grease lubricating wind turbine bearing mechanisms, high pressure intrinsically safe units for offshore oil drilling additive injection, and for biodiesel plants converting bio waste into sustainable biofuels.

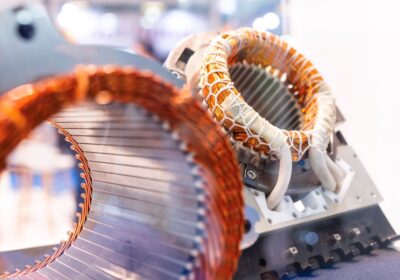

Monitoring Grease Lubrication Flow in Wind Turbines

One of the fundamental requirements for ensuring reliable and efficient wind turbine operation is to keep the heavily loaded main bearings fully lubricated in all operating conditions. Fully IP65 / NEMA 4 compliant, Titan’s compact oval gear flowmeters are optimised for measuring the flow of viscous liquids. Designed to operate at pressures of up to 700 bar and temperatures up to 150°C, and with a standard flow range of 0.01 to 4.0 litres/min on 30Cstk oil, the OG1 or OG2 models can routinely achieve outstanding accuracy (0.75%) and repeatability (0.1%).

Optimum Flow Meter Accuracy Critical to Biofuel Production

Titan’s Oval Gear (OG) flow meters are an intrinsic component within Green Fuels’ biodiesel plants converting bio waste into sustainable biofuels. Green Fuels’ award-winning research and pioneering process plants have powered buildings with sustainable fuel from used cooking oil, with ongoing development to convert fish oil and sewage sludge into biofuel. Simple, accurate and chemically resistant, Titan’s OG flow meters, with the addition of the Namur switch, have proved the ideal solution for precise chemical dosing for Green Fuels’ biofuel plants within a potentially hazardous environment.

Adaptive Flow Measurement Designs for Petrochemical Applications

Titan Enterprises offer special options and adaptive designs of its Oval Gear (OG) flow sensors to meet specific high-pressure requirements, aid chemical compatibility, and ensure safe operation in potentially explosive atmospheres. Titan’s Oval Gear range include ATEX compliant IP65/NEMA 4 protection models, and devices that offer intrinsically safe options for processes that operate within harsh environmental conditions, such as explosive or corrosive atmospheres, where flowmeters are required to withstand tough environments whilst maintaining accurate and reliable measurement.

The pivotal role of oval gear flow meters lies in controlling precise liquid dosage for efficient and economical process operations. Within the petrochemical sector, a chemical injection system employs accurate low-flow measuring sensors to inject a precision dosage of chemicals required, including antifoaming scale inhibitors and methanol, into oil wells. Accurate chemical dosing is essential for the optimal functioning of the well system, promoting efficiency and heightened productivity without excessive costs. OG flowmeters are critical in preventing overdosing that can lead to unnecessary expenses, or under-dosing that may trigger premature maintenance and suboptimal well performance.

For measuring high viscosity liquids like thick oils, bitumen and tar, precision-engineered flow meters are necessary. Titan’s standard OG flowmeters are designed to provide highly accurate flow measurement up to 1000 cSt. For viscosities above 1000 cSt, Titan provides High Viscosity OG options specially designed with profiled gears to facilitate additional flow of the liquid and prevent hydraulic lock.

Visit Titan Enterprises’ website for further information on flow measurement or to discuss specific OEM applications, please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk.