ABB automates warehouse operation in instrumentation factory in Italy

- ABB has transformed the warehouse operation at its instrumentation factory in Ossuccio, Italy by introducing a fully automated storage and retrieval system

- Automating logistics has led to a 90 percent improvement in overall logistics efficiency at the factory

- The ABB OmniVance™ FlexBuffer™ robot system manages all warehouse loading and offloading activities

From a manual activity to fully automated warehouse operations, ABB has completed the transformation of the logistics operation at its instrumentation factory on Lake Como in Italy. The upgrade was aimed at improving logistics and achieving overall operational efficiency.

The fully automated storage and retrieval system is critical since the

process handles one piece every three minutes.

By introducing a fully automated storage and retrieval system, ABB has achieved a 90 percent improvement in overall logistics efficiency at the factory. Eliminating manual handling has also reduced the time required for final assembly of packages by 30 percent. This improvement is critical since the process handles one piece every three minutes.

“We wanted to improve logistics at the Ossuccio site, while also enhancing the entire manufacturing process,” said Mariafrancesca Madrigrano, General Manager of the ABB Measurement & Analytics factory in Ossuccio. “We constantly strive for operational efficiency through innovation and are always looking for ways to better address customer needs and ensure customer satisfaction.”

Adoption of the system has alleviated the physical strain associated with manually handling heavy boxes.

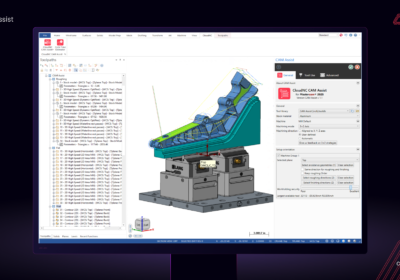

The solution consists of two ABB OmniVance™ FlexBuffer™ systems connected by a conveyor, each one equipped with ABB robots to enable efficient order handling. FlexBuffer allows for easy transitions between buffering, storing and sequencing tasks. It excels in efficiently combining temporary storage and sequencing functions, giving it a competitive edge over traditional systems. The mixed item variant of the FlexBuffer enables the user to store a wide variety of box sizes, all being handled with the same robot gripper. Because of the dynamic racking positions all boxes are stored with minimal loss of space.

FlexBuffer allows for easy transitions between buffering, storing

and sequencing tasks.

Adoption of the system has enhanced working conditions for operators, alleviating the physical strain associated with manually handling heavy boxes. In addition, the workforce was reallocated to other manufacturing areas that required additional manpower, giving the factory a greater flexibility during production peaks.

The ABB Ossuccio factory is specialized in the production of pressure transmitters.

The ABB Ossuccio factory is specialized in the production of pressure transmitters that enable industrial companies around the world to measure, monitor, and control applied force. Key for both safety and efficiency, pressure measurement is fundamental in industrial digital transformation. The factory exports 90 percent of its production.