~ Experiments and fault diagnosis are cheaper and easier in simulation ~

Engineers are, by nature, bold. To build or fix something, often with thousands, or even millions, of pounds on the line, and to say with confidence that it will work, is courageous. Despite that, the advent of power system modelling has brought surety to engineers, meaning they can demonstrate their designs will work before even flicking a switch. Here, Ryan Kavanagh, director of excitation control specialist Excitation Engineering Services, explains the transformative impact of power system modelling on the control engineering sector.

The ability to create a simulated version of a power system, whether a generator, industrial site or even commercial facilities, is self-evidently a very powerful tool. These models can produce simulated data to show how a power system might perform under certain conditions and operating scenarios, such as peak demand, voltage variations, fault analysis or even integration of renewable energy sources.

The offline and unintrusive study of a system’s behaviour in different scenarios without having to stop or interrupt its function is incredibly valuable. Indeed, some fault scenarios are impossible to test without simulation, as they would severely damage or destroy equipment.

Some information, such as performance and historical electrical nameplate data, cannot be collected during plant operation. This data is especially important for aging assets and legacy equipment where original documentation is unavailable. Suspending production, either because of faults or just for investigation, can cost tens of thousands of pounds per hour.

The financial implications are not the sole reason for this practice’s importance. The Grid Code, the collated technical requirements for connecting to and using the National Grid Electricity Transmission (NGET) system, mandates that computer models should be submitted for any excitation control system (PC.A.5.3.2.c). This is a legal requirement for any generating units or synchronous power generating modules to be connected to the NGET.

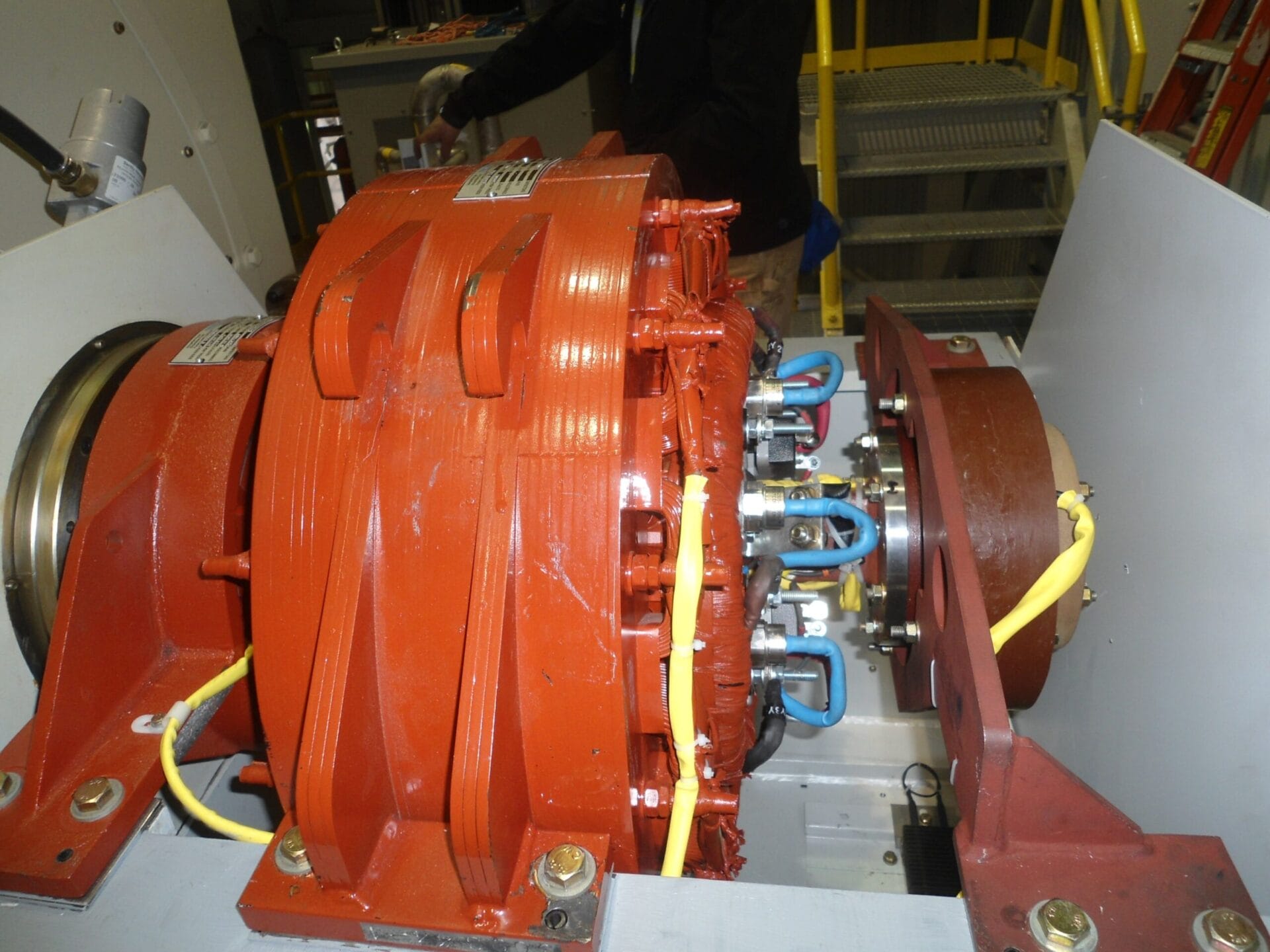

Typically, engineers will travel to the site and take electronic measurements from the system designated for study. Constructing the model in the software of choice is time-consuming and challenging. Once complete, however, the engineers will model different conditions and scenarios. This trial and error approach has two uses: either it can prove that a system will operate safely, complying with standards or guidelines, or it yields the same aberrant readings obtained from the real system, enabling a diagnosis and recommended treatment.

Models represent reality

Without proper validation and verification of the models’ output, these simulations would be useless. Verification means demonstrating that the data output from your model matches up to your specified requirements. For example, do the mathematical equations governing the system’s behaviour correspond to the simulated code?

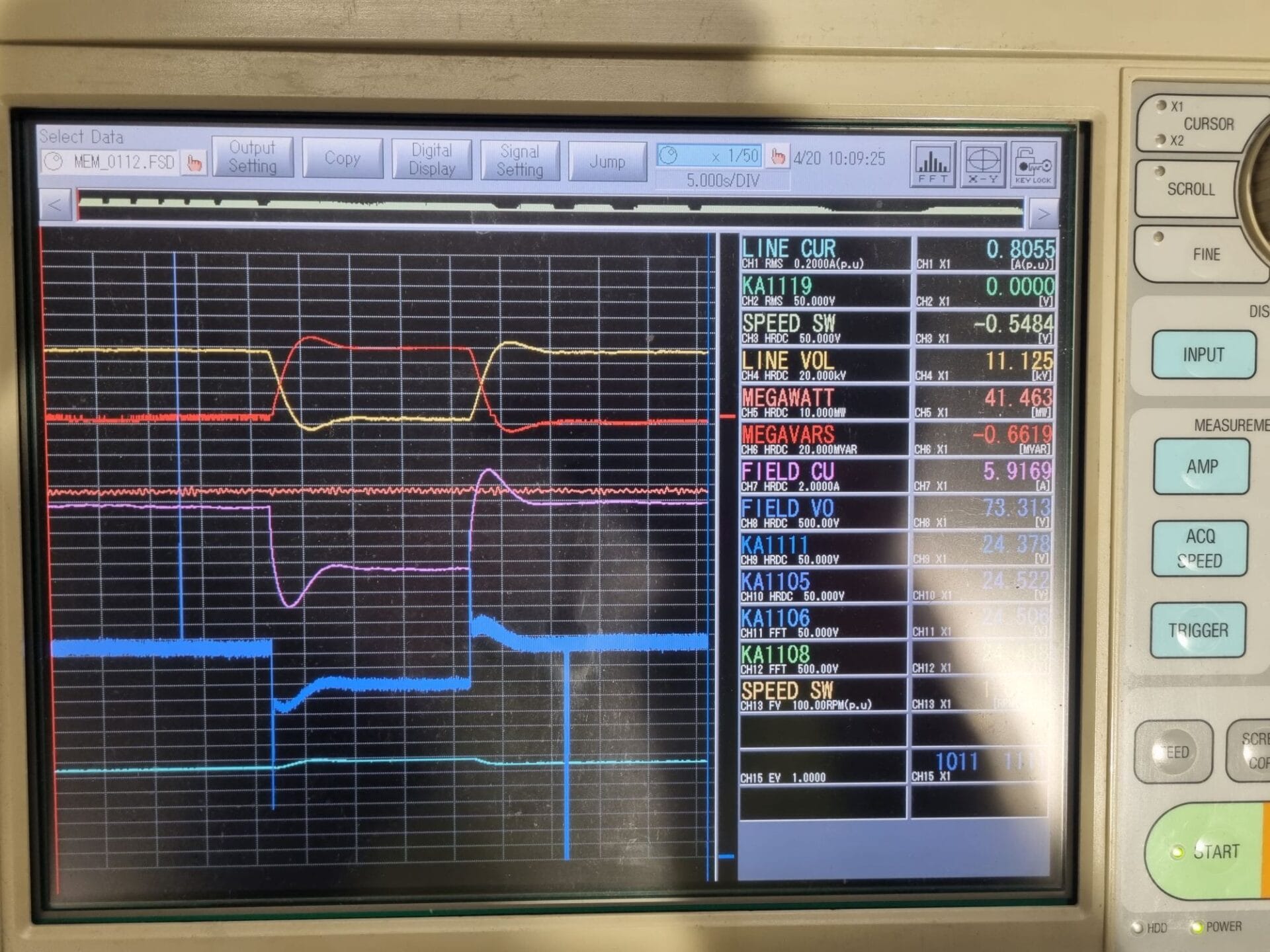

In slightly different fashion, validation means showing that your model behaves as the real power system would outside of your simulation. This involves using real-world observed data or field measurements to compare against the model’s output, to ensure that they match up. While validation appears to be a simple comparison of real and simulated results, both this and the verification process are complex and rely on the sort of experience that excitation engineers have within this specific area of knowledge.

In early 2024, EES had a customer report a fault with an excitation system. Our engineers took measurements onsite and built a model of the system when they realised the excitation supply current readings were peaking abnormally. After running many experiments in MatLab SimuLink, they produced readings that matched up to the measurements taken and identified a periodic fault.

The customer, VPI Immingham, shared the trace imaging with the equipment manufacturer. The manufacturer instructed VPI to examine a specific part of the system, where engineers found several burnt-out components. VPI was then able to replace these components and rectify its issue.

Power system modelling is an essential service in power generation engineering. The rarity of companies that offer on-site investigation, laboratory modelling and fault diagnosis in one package represents an area for the industry to grow. Companies such as EES have the technical capability and the decades of expertise to prevent extensive, expensive downtime and allow engineers to get back to being bold.

To find out how EES’ power system modelling could help you understand your power facility better, visit https://excitationengineering.co.uk/consultancy/